Our group assignment was: review the safety data sheets for each of your molding and casting materials, then make and compare test casts with each of them

The oomoo was pretty straight forward. We just had to mix two parts of each separately and then mix them together. It's important to not get any in contact with your mouth or eyes and not use the mold for anything that will be ingested. To reduce contamination glasses and gloves should be used. The room should also be properly ventilated

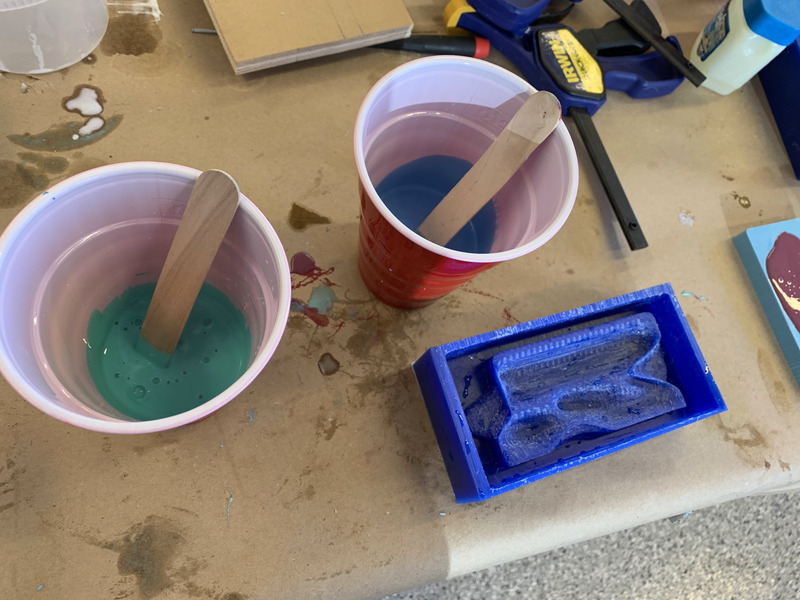

When pouring a uniform flow is ideal and then allow to cure for about 2 hours.

The SDS for hydrostone can be found here. Reviewing the SDS, we found that hydrostone was not particularly more harmful than any of the other materials we were working with so we can follow the same procedures generally, but it is somewhat unique in that it comes in a powder. As such, there is a hazard to breathing it in, which might be easy to do as dust could get knocked into the air as we scoop and mix. We already wear masks in the lab for Covid, but they provided some extra benefit for when working with hydrostone. We'd probably want to wear masks anytime when working with something like this.

We poured a few test casts of hydrostone while doing our training. The biggest material-specific highlight is that we want to let the cast dry in the mold for a few (~5-6) hrs, then remove it from the mold and let it dry in a well-ventilated place, preferably with moving air. We had a vent in the lab that was great for this.

The SDS for smooth-cast 305 can be found here.

Plastic needs to be used with gloves and in a well-ventilated area. It is more likely to have bubbles when it was poured, so after mixing and before pouring, we used the vacuum chamber to pull the bubbles out of the mixture. After doing this, there were very few bubbles on the surface after the pour, and in the final product. It was also easily dyed with just a few drops of colorant during the mixing stage, and the color was consistent throughout. The plastic has a much shorter pot time (7 minutes), so needs to be mixed and poured with more urgency than the oomoo. It also takes a shorter time to set, and can be taken out of the mold in 1 hr.