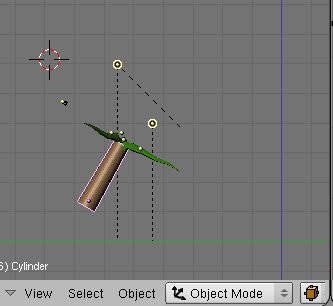

tree growing movie

tree growing movie

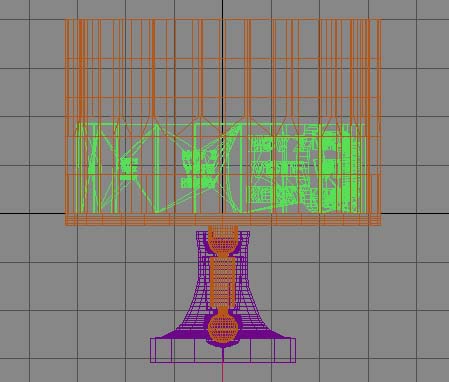

Our first assignment was to make a model of our current idea for our

final project. I was interested in the idea of making a small robotic

tree, one the would slowly grow up during the day in response to time

and touch and then bloom into a lamp in the evening. It would then

shrink down during the late night. I used blender to make a small model

and movie.

tree growing movie

tree growing movie

Sep 24, 2004

Hoping to make a press-fit dress for this week's assignment. Started to

play with making a little dress model out of paper just to see how I

wanted things to fit together. Will try to take a pic and post it

later.

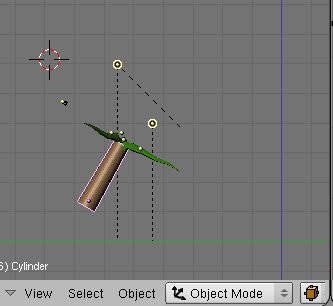

Sep 27,2004: Modern-day Cinderella

If Cinderella was

written today, she's have a fab lab instead of a fairy godmother.

Inspired by this, i wanted to create whimsical fashion. I originally

hoped to make a dress ala the photo above, but time and other

constraints (queues for laser cutter at 3 in the morning...) meant that

i made a crazy halter top (of the dress) out of acrylic and cardboard

using the laser cutter. I also made a necklace and a belt using the

water jet. The jewelery was a lot of fun to make and I was happy with

how it came out.

Things Learned:

i am the modela guru. click here for my notes on using it.

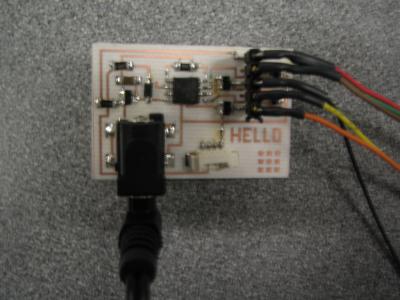

Made a circuit board. Had a little trouble setting the z-axis (see my

notes on the modela page on how to do this) until i talked to raffi.

Then stuffed the board and made some wires. Things I learned:

Sep 29, 2004: The Joys of Wires

Ah so it looks like the serial connector cable I made yesterday is not so good. I now need a new serial connector piece (must learn correct term for this) so I have to come back tomorrow. A few notes on this:

Oct 2, 2004: SCSC (Serial Connector Saga Continued)

I had a lot of trouble making a serial connector that worked. My

board was fine (though taking off the clip once took the

microcontroller with it, so I had to resolder the microcontroller to

the board) but the connector was awfully finicky. I got it working two

separate times only to later have the wires fall out. Lame. Anyway

looks like tonight I finally got the serial connector mostly right. Now

I have a cute little board which tells me to "viva la vida"!

Oct 12, 2004: Too Easy, Too Hard, Just Right-- Notes on the 3D Scanner

From my current experience, I think that the 3D scanner is useful for objects that are moderately complex, primarily consisting of straight lines. Very simple objects are easily created in 3D modelling programs, and very complex objects (in particular, objects with lots of holes) are hard to scan well. I tried scanning a mobius strip with holes in it. The result is below (or at least will be once I get the graphic up). It is a pretty complex shape with a number of holes. It requires scans at a number of angles to get a good perspective of the entire object.geomagic appears to get grumpy if one tries to merge too many scans, and so this was problematical. Tips:

Oct 13, 2004: Making Programs Play Together Nicely

I'm using 3D Studio Max to design something to print on the Z corp. The Z corp accepts .stl, vrml2 and .pyl files. Below are some tidbits about using these two programs:

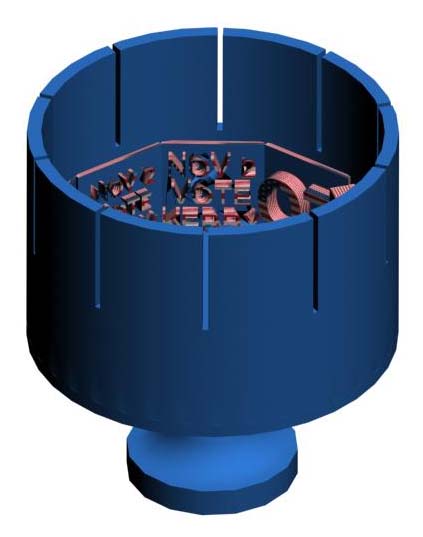

This week we had to play around and make something with the 3D scanner and one of the 3D printers. i wanted to create something that took advantage of the 3D nature of the printer and i thought it would nice for the object to be topical. The upcoming election is looming large in my mind and we've all been inundated with debates, advertisements and news coverage recently. While you frequently have to read between the lines to figure out what the candidates' true priorities are, I decided to make an object that was not so subliminal.

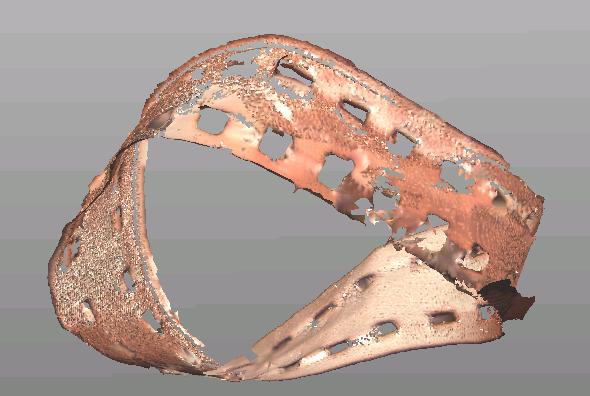

Oct 18, 2004: Escher Wanna-be

I was interested in making a shape which confuses the eye, ala Escher's mobius strip. I made a mobius strip out of paper and then scanned it using the 3D scanner. I was initially planning to add ants or another creature walking around on the strip and then print it. Dues to some issues I mention in another entry, scanning the strip didn't turn out quite as well as I was hoping. I imported it to use on the stratasys but the software complained since the part was still not quite closed. I elected to print something else.

|  Photo of Mobius Strip Photo of Mobius Strip |

Scan of Mobius strip Scan of Mobius strip |

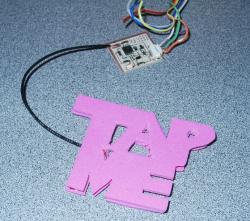

For assignment 5 we were supposed to take a efe board (schematics and code available here) and modify it in some way to add interactivity to something. I oriignally tried to use the vinyl cutter to make my circuit. My circuit came out fine (after some experimentation with getting the force and speed settings) and it even worked when I downloaded the code-- yeah! But the b value wasn't correct. When I tried to start taking the programming clip on and off the board (and general board handling) my copper traces started coming up from the epoxy film. This continued until they started to come apart and my board just wasn't working. I've misplaced that board right now but I'll try to find it and take a photo so I can show what it ended up looking like. I think the vinyl cutter is fine as long as you don't have to handle the board too much. I should have covered the board with sealent or super glue or epoxy to keep all the components safe as soon as I knew it was working.

I decided to make a sensor that makes a noise that depends on the capacitance (a rough measure of how close you are). The more you cover or press the sensor, the higher frequency of the noise. I made two programs for this. In one you can tap on the sensor and see a ball get larger and the tone get louder as the capacitance increases. The other is a simple game where you try to match the size of a rectangle by pressing or covering the sensor to make another rectangle the same size. When you succeed you hear a ping and the file displayes "matched!" The inspiration for this is those games at fairs where you try to swing a hammer to make a disk shoot to the top of a tower.

|

|

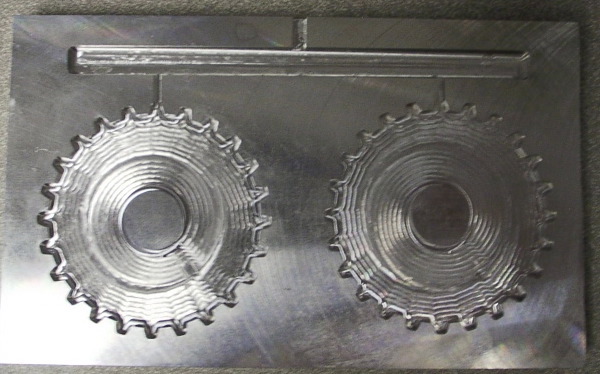

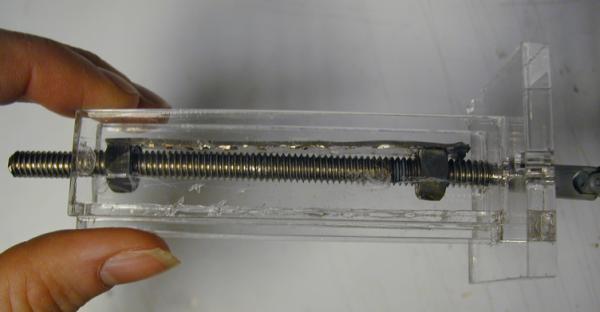

Nov 1, 2004: Gear Dreams: Part 1

Ah the pull of moving parts. This week's assignment was to make a mold using the NC mill that the following week we would use for injection modling. The nice benefit of molds is that you can make many items very easily. So I'm hoping to make a display of gears with LEDs for next week. I'm hoping the gears will mesh but I may need to use a smaller tool to machine the mold: due to time constraints we used a pretty small tool but it may not be small enough.

|

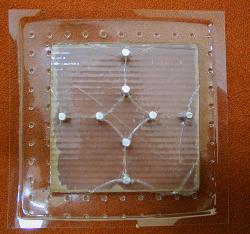

still need pics for this. i wanted to make a display of gears, maybe involving LEDs. i got ambitious and thought of making the display using the vacuum former. turns out it's hard to do precise engineering with the vacuum former since the vacuum often moves not-so-stiff objects about, so the display didn't quite work. close though. and i made some fun vacuum shapes on the way. pics later

still need pics for this. i wanted to make a display of gears, maybe involving LEDs. i got ambitious and thought of making the display using the vacuum former. turns out it's hard to do precise engineering with the vacuum former since the vacuum often moves not-so-stiff objects about, so the display didn't quite work. close though. and i made some fun vacuum shapes on the way. pics later

|

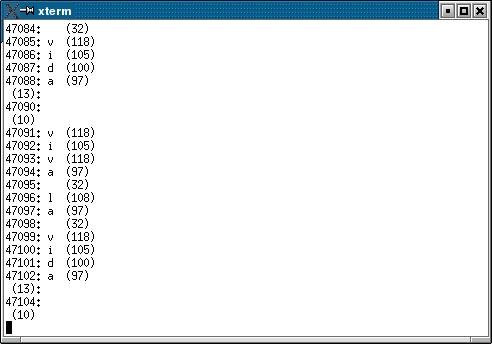

This week's assignment was to play around with motion control. Vincent gave us a great tutorial on how to use the chemical etcher (see limor's written tutorial here. So I now have a chemically etched board and a modella milled board. I was silly and didn't allow quite enough width when I was milling so the top trace is dangerously thin in parts. I think the board would still work fine if I used a jumper cable, but I elected to just use my chemically etched board for now. Today I stuffed my board and got it to work using the code Neil gave us (hello9 wave stepper code). I'm hoping to attach my motor to something to do convert rotary motion to linear motion. A small video of my board working doing the basic "hand waving behavior" is here (thanks to burak for letting me borrow his digital camera to make the movie and take the photo!).

Nov 14, 2004: Linearity

|