This week's assignment was not too complicated, just find something to vacuum form using the machine. This is the machine used:

The process to vacuum form something is really straightforward, no fancy algorithms or formulas and no 3-hour preparation or complicated designs; heat a plastic and make it take the shape of an object. This picture shows the plastic being pressed by the black metal and the plastic holder.

Once the plastic is in place, the only thing to do is to turn on the oven-like knobs on the machine so it heats the plastic. You have to put it on top of the plastic of course, but you may take a look to check how much it has swooped and know if its ready to be formed. This picture shows the plastic already heated and almost ready to be formed.

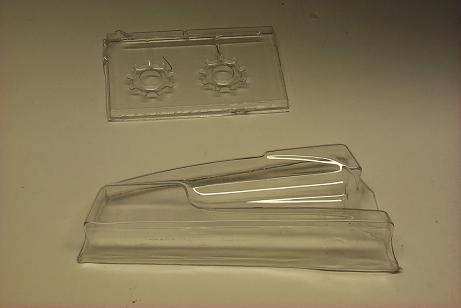

After forming the plastic, you'll end up with a square sheet of plastic with the formed shape in the middle, so it only remains to cut it from the square to get this: