It's milling time! First of all, the milling machine CAN KILL YOU, so better use with caution. The first step in the milling / inyection molding process is to create your design in a 2D imaging software like Corel Draw. In my case I decided to make a set of gears, which are shown here.

Once the design is ready, its necessary to create the 3D features from the 2D file, like extruding, pocketing, island creation and several more features using the allmighty FeatureCAM software.

After creating the features, specifying the depth of the milling process and several other configurations, its a good idea to simulate the process to see if the final result is what you expect. In this case, the process used two kinds of tools a larger one to make a rough image of the gears and another pass using a finer tool to detail the edges and give it a nicer finish.

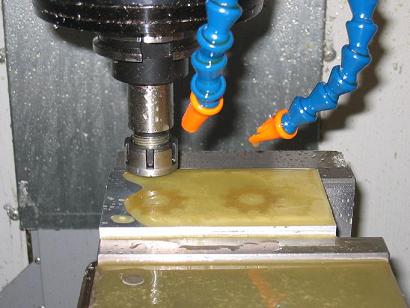

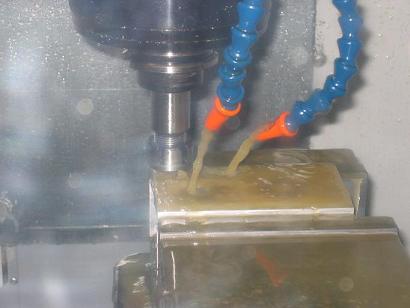

If the simulation gives the result you want its time to mill your part. Its interesting the huge possibilities of this technique since you can manufacture anything from a combustion engine to a plane turbine or lego molds. In this picture the mill is generating the mold that I'll use later to create my plastic gears using the inyection molder.

If everything went well, you should now have a mold that you can use to inyection mold your pieces. This is the inyection molder. Its got a compartment in the back to pour the small plastic pellets that it melts to inyect them into the mold. Its possible to use different colored pellets to get colored parts.

Here I'm pulling out the mold once it has been inyected with plastic. You can see red melted plastic coming out of it. It happens that the molds do not perfectly fit each other because they need to be polished, but in this case we didn't worry about that.

After pulling it out from the machine you need to take out the mold from the metal containers that press it together to keep the plastic in.