While I was playing www.terraserver.com and www.terraserver.microsoft.com, I was able to find my neighborhood and my house.

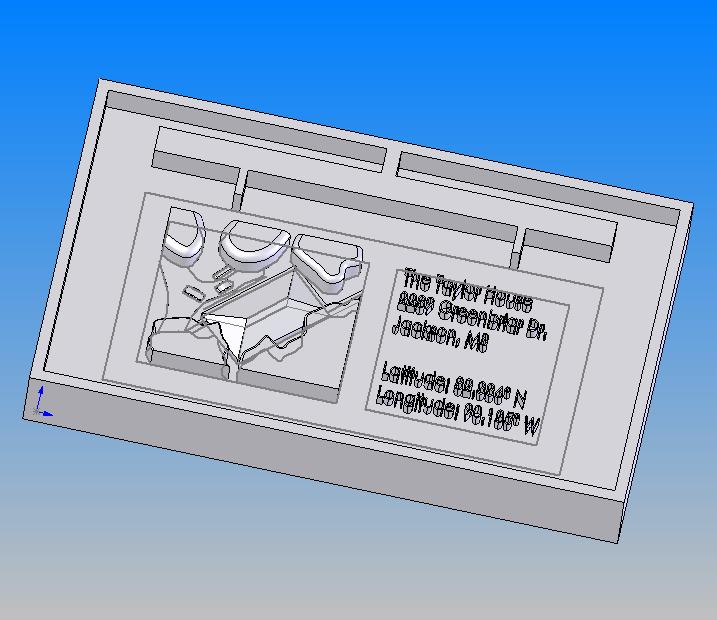

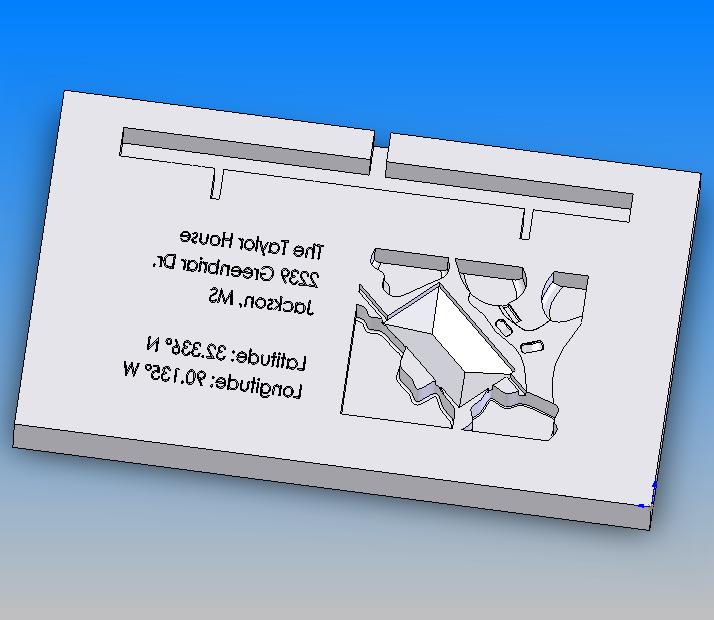

Deciding to make a complicated mold, I modelled my house in Solidworks, using the satellite imagery to provide a footprint.

I then changed the extruded form into a mold.

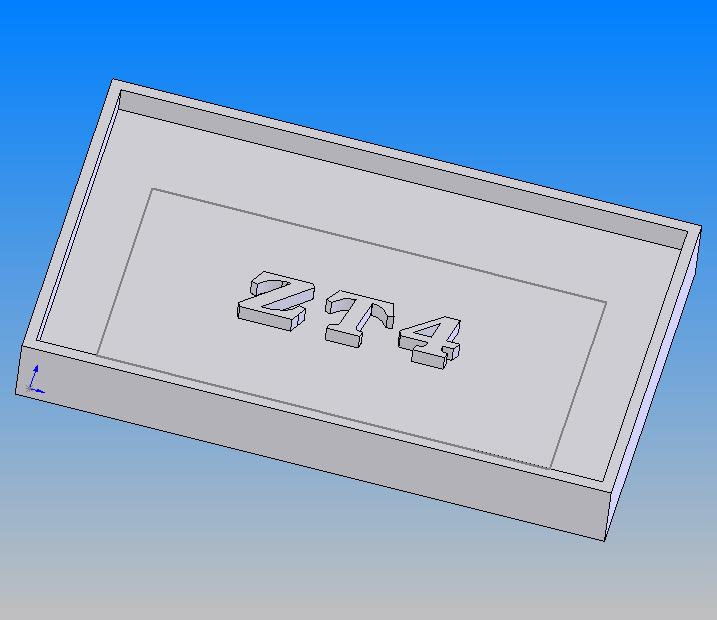

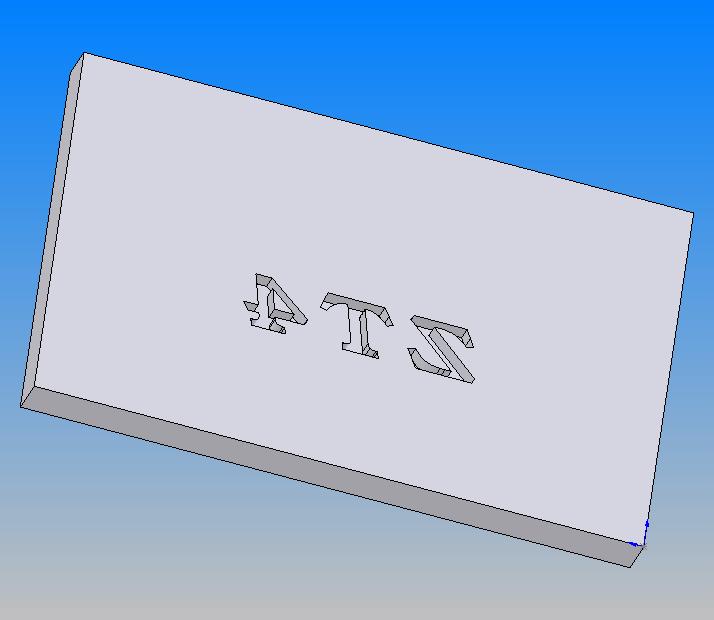

Unfortunately, the house in this mold, roughly 1.5 inches by 1.5 inches, would take five hours to mold. At John's recommendation, I decided to try something simpler, my initials. I generated this mold in Solidworks as well:

This mold took about 15 minutes to mill. The file imported from Solidworks used surfaces to form the text where curves would have been convenient, so a simple dxf file was created which also had my initials on it. It was then used to make the mold.

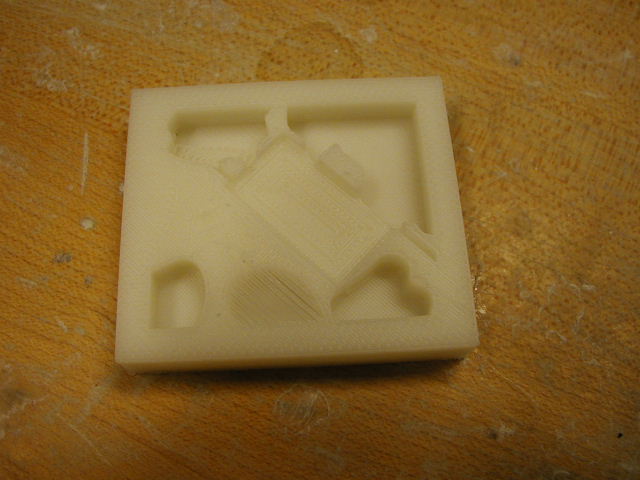

Not wanting to abandon my initial idea, I printed the "mold" of my house on the Stratasys.

Before the house mold printed, I was alerted that there were open curves. When the house printed, there were some extra bits of plastic that I had to break off. I believe that the extra plastic was because of a conversion error that created the open curves. Here is the mold before I broke off the extra plastic:

Of course, the aluminum mold was put to good use as soon as I got home.