assignment: To construct a press-fit kit using either the laser

cutter or the vinyl cutter.

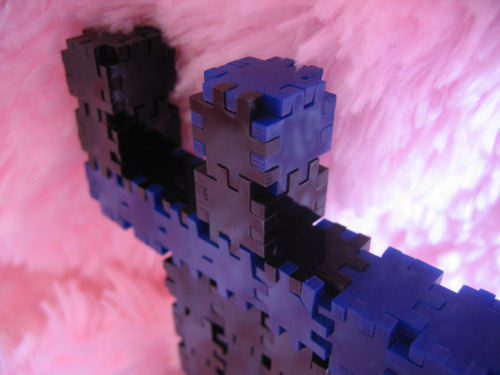

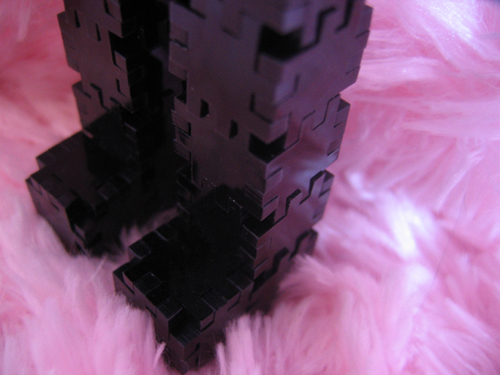

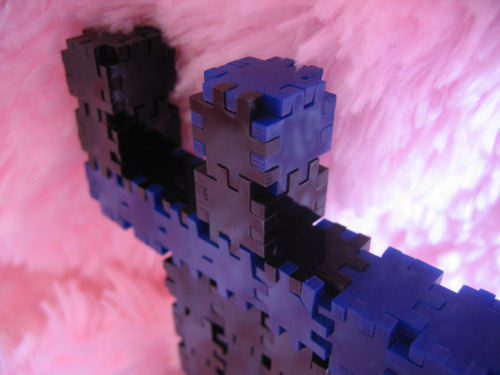

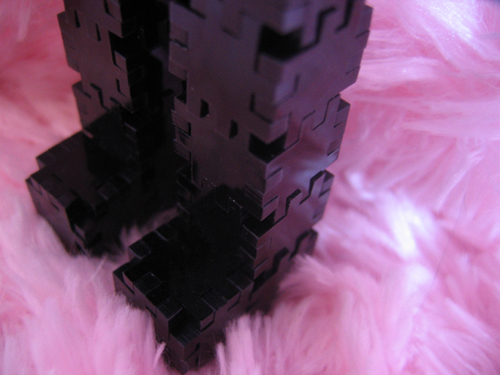

details: For this project I developed three designs. The first,

and most straightforward, was a simple 3D press-fit construction

kit using a single primitive shape. I designed the shape in OODraw

without introducing any additional processing tollerance under the

assumption that I could make the necessary adjustments in the cam.py

application. My intial attempt, using colored 1/8" acrylic and the

recommended settings proved ill-fitting. On my next iteration, I

increased the contour offset from .00 to .01 and the pieces seemed

to fit together well. When I took the shapes home and tried

assembing them though I discovered that there was more variablity

in the shapes than I had expected, resulting in a number of broken

pieces. I returned to the lab and cut more pieces with roughly the

same result. It was only upon inspection of the burn patterns on the

cut pieces that I realized that the material was warping during

cutting, resulting in the variation I saw in my shapes. Fortunately

I had enough well-fitting shapes to construct the simple model

depicted below. In general though it seems that acrylic tends to warp

under laser cutting and some measure might need to be taken to

ensure that the acrylic remains flat during cutting.

-> OODraw .sxd file of construction kit

My next design was a press-fit acrylic bike chain. The idea was to

introduce rotational motion into an object built from 2-D pieces.

With any luck I'll get this thing cut in the next few hours.

-> OODraw .sxd file of chain

My final design was a belt, again exploring the idea of introducing

free rotation into an object built up entirely from 2-D peices.

Additionally, this belt would include a crude latching mechanism

the functioning of which will depend upon the flexiblity of the

arcylic material.

-> OODraw .sxd file of belt

-> OODraw .sxd file of construction kit

My next design was a press-fit acrylic bike chain. The idea was to

introduce rotational motion into an object built from 2-D pieces.

With any luck I'll get this thing cut in the next few hours.

-> OODraw .sxd file of chain

My final design was a belt, again exploring the idea of introducing

free rotation into an object built up entirely from 2-D peices.

Additionally, this belt would include a crude latching mechanism

the functioning of which will depend upon the flexiblity of the

arcylic material.

-> OODraw .sxd file of belt

-> OODraw .sxd file of construction kit

My next design was a press-fit acrylic bike chain. The idea was to

introduce rotational motion into an object built from 2-D pieces.

With any luck I'll get this thing cut in the next few hours.

-> OODraw .sxd file of chain

My final design was a belt, again exploring the idea of introducing

free rotation into an object built up entirely from 2-D peices.

Additionally, this belt would include a crude latching mechanism

the functioning of which will depend upon the flexiblity of the

arcylic material.

-> OODraw .sxd file of belt

-> OODraw .sxd file of construction kit

My next design was a press-fit acrylic bike chain. The idea was to

introduce rotational motion into an object built from 2-D pieces.

With any luck I'll get this thing cut in the next few hours.

-> OODraw .sxd file of chain

My final design was a belt, again exploring the idea of introducing

free rotation into an object built up entirely from 2-D peices.

Additionally, this belt would include a crude latching mechanism

the functioning of which will depend upon the flexiblity of the

arcylic material.

-> OODraw .sxd file of belt