assignment: To construct a press-fit kit using the water laser

and multiple materials.

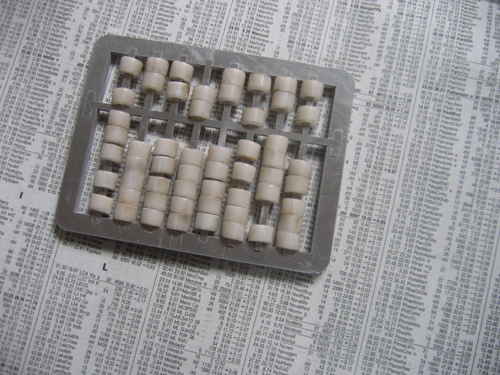

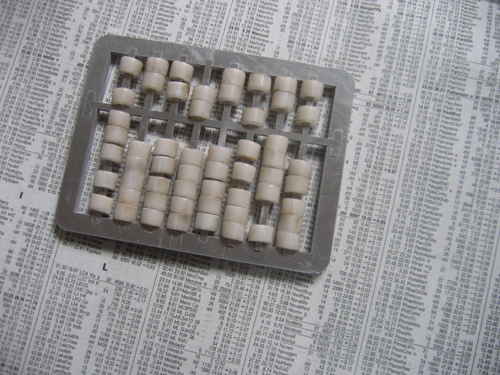

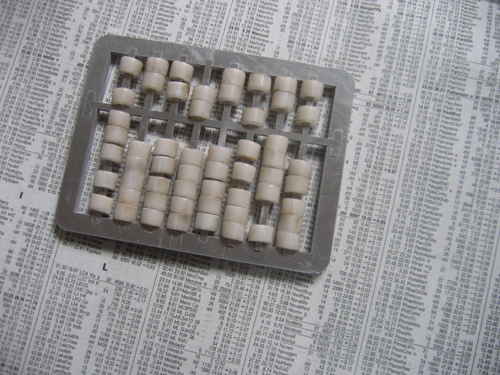

details: For this assignment I decided to build a simple, portable

abacus using both the water laser and HeNe laser. I tried using Omax

to develop the design but found it somewhat difficult to use. I chose

to use Illustrator instead and aside from a few hitches importing the

.dxf files I found it much easier to work with.

For my first attempt to cut the parts I used an offset of .015 inches

for both parts. After cutting the pieces I found that they did not

fit together as smoothly as I had hoped. After speaking with John I recut

the inside piece using a slightly smaller offset (.014"). Again, they

did not snap together easily. Manu pointed out that the metal showed

a bit of a slope through the thickness and that by filing the pieces

just a bit I could probably get them to press fit. I felt a bit guilty

about this as it seemed at odds with the assignment but John assured

me that post-cut de-burring and filing was often necessary.

After filing the pieces to press-fit I began to cut the abacus "beads".

Initially I had hoped to cut thin concentric rings of acrylic of different

color and thickness to ensure that the beads would be easy to move

individually. It soon became clear though that the dimensions of the

beads were such that heating effects were distorting the final part

shapes and I resorted to a single part bead. Upon assembly this seems

fortuitious as the beads are easy to move singly and would likely have

been very time consuming to assemble otherwise. Further, the effects

of laser cutting the acrylic rendered the beads somewhat discolored

and non-uniform which actually looks more interesting than more regular

shapes might have.

-> .dxf rendering of traval abacus

-> .sxd rendering of traval abacus beads

-> .dxf rendering of traval abacus

-> .sxd rendering of traval abacus beads

-> .dxf rendering of traval abacus

-> .sxd rendering of traval abacus beads

-> .dxf rendering of traval abacus

-> .sxd rendering of traval abacus beads

-> .dxf rendering of traval abacus

-> .sxd rendering of traval abacus beads

-> .dxf rendering of traval abacus

-> .sxd rendering of traval abacus beads