Water-jetting Stone

I first acquired some stone from Home Depot. They sell stone tiles as flooring, though almost all the tiles are ceramic with a finish on one side, which seems good for flooring but not if you're going to cut it into a shape where both sides are visible. The do however have a few kinds of marble as 12" square tiles, so I got some of those.

For this material, we set turned on the settings for brittle material and slow start, and also added 3 wiggles. This worked well for cutting without crumbling the material.

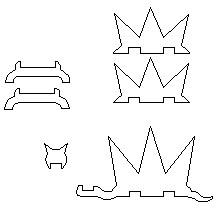

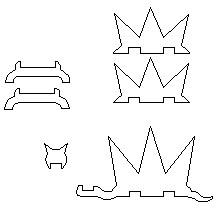

I designed some parts meant to assembled together with interlocking slots, however I did not imagine there would be much give to the marble so I left a little extra space in the slots so they could slide without deforming

However, I did not leave quite enough space and the stone broke apart when the slots were fitted together.

After decreasing the toolwidth by 0.0015", the pieces almost fit perfectly. Some imperfections in the cutting prevented the pieces from interlocking, but these were easily scrapped off with a knife. I was surprised how much the cut increased from the top of the material to the bottom, even before widening the cuts the widest part (bottom) of the slots always had enough room to fit together.