| Eleventh Assignment - 28nov2005 |

The vacuum forming machine is quite a lot of fun, and very simple to use. The most significant parameters to note are the crushability of that which is being molded, and the desired softness of the molding material (we used 'pet g'). Both require a bit a trial and error...

|

| Eleventh Assignment - 28nov2005 |

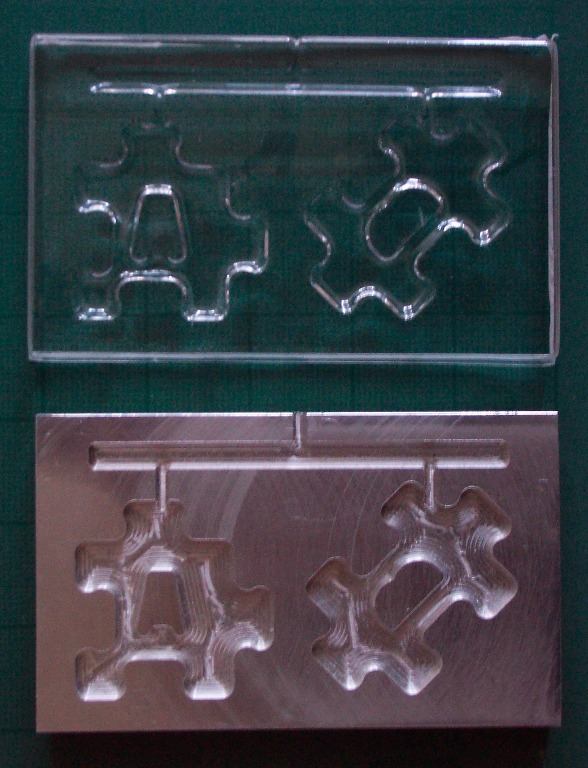

The first thing that I molded was my injection molding plate. Surprisingly, the resolution of the resulting mold is very high (the maybe ~2 mil milling pattern marks were transfered). The primary limiting factor, for this piece, was the ability of the vacuum (sourced through holes on a surface plate) to maintain air paths to all empty parts of the piece. It is an interesting problem (preventing bubbles), that only shows up with a non porous material that has many concavities.

|

| Eleventh Assignment - 28nov2005 |

Having so much fun, I decided to throw my phone into the molder. John mentioned that people had done this before, without destroying their phones (with the heat), so I decided that the risk was small enough. For extra measure, I kept the phone out of the machine until the pet g was ready (I put the phone in through the side), to avoid the radiant heat that makes it through. Again, the resolution of the resulting mold was fantastic (i.e. sticker text was apparent).

By molding one side, then trimming it down to a shape that could be easiy removed, then putting it back on the phone and molding the other side, I created a snap-together case for the phone. Beware, if trying this, that it takes quite a bit of effort to initially extract the phone from the mold, before trimming it, without damaging the phone. Heavy diagonal cutters, pliers, and a dremel tool are suggested operating tools :)

|