How To Make Almost Anything Class

Lassiter's WEEK #3 Assignment

The assignment for this week was to make a 3D object using two different machines

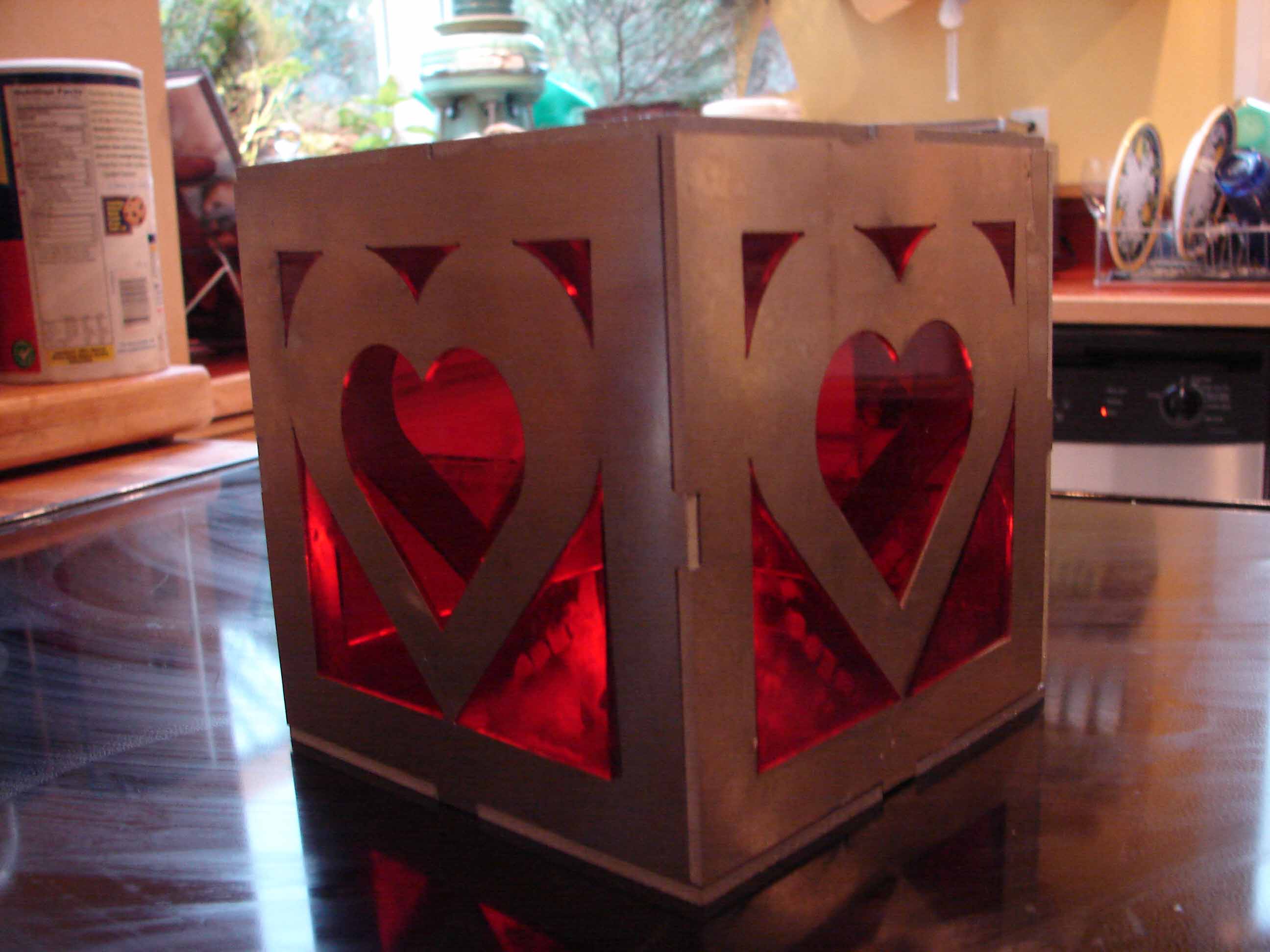

and two different materials. I chose to make an aluminum box frame with a heart shape design inside,

and with red acrylic in all the spaces such that it looked like stained glass. The box serves as a

decorative

candle holder.

The materials used were aluminum and acrylic, the machines used were the OMAX waterjet cutter and

the Universal laser cutter.

I started with an OpenOffice drawing-- made the design and then took it into the OMAX Layout.

OpenOffice file

There were some transfer difficulties... OMAX didn't see all the lines in my OO file, and there were

some other minor issues, but DiFrancesco helped sort them out. We used aluminum of 1/8th inch thickness.

The file cut perfectly the first time, and the fit was just right-- except for the bottom of the box, which

I needed to re-work to incorporate a slight offset caused by the thickness of the material. Otherwise it

worked beautifully.

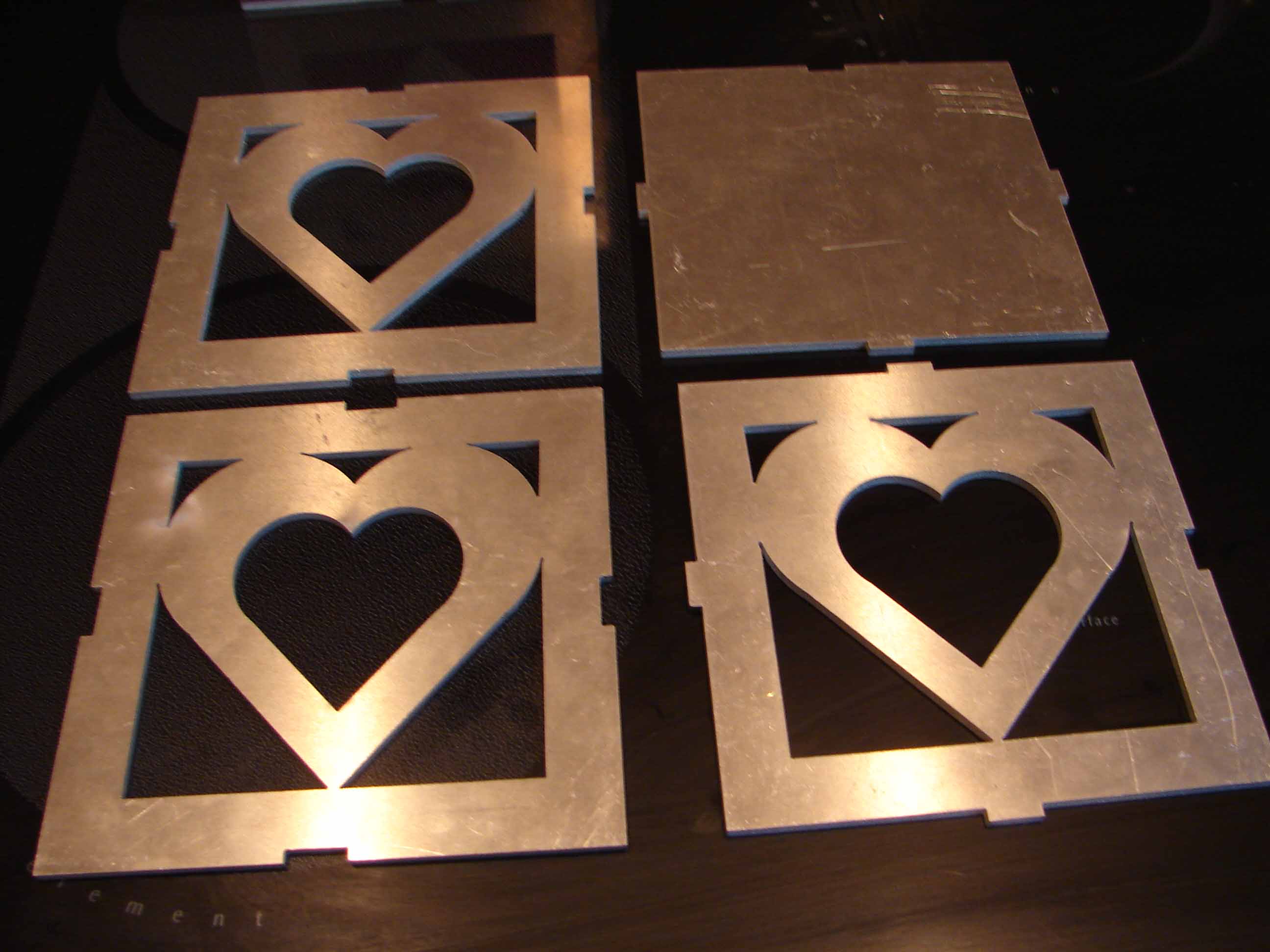

Aluminum sections made by waterjet cutter.

The difficulty came in changing machines and materials. First I cut a one to one scale of the OO file on

the laser cutter, using left over refelctive acrylic for my prototyping materials. I had terrible touble

transferring the OO file into the cam tool-- in general we seem to be having trouble with OO files

now-- they all trasfer in with some bugs. Cam translates long smears for some of the lines in the files.

Additionally, cam would not scale in the .001in range, only in the .01in range-- and I needed the

more precise resolution for fitting. So I had to switch to Corel Draw and rework the files a bit

in order to print/cut them on the Universal. In the end I had to use Corel Draw as my software and to

print. Once I finally cut the pieces successfully--I fit all ofthe interior space pieces into the

appropriate slots, and as expected, they were all too small for a good press fit.

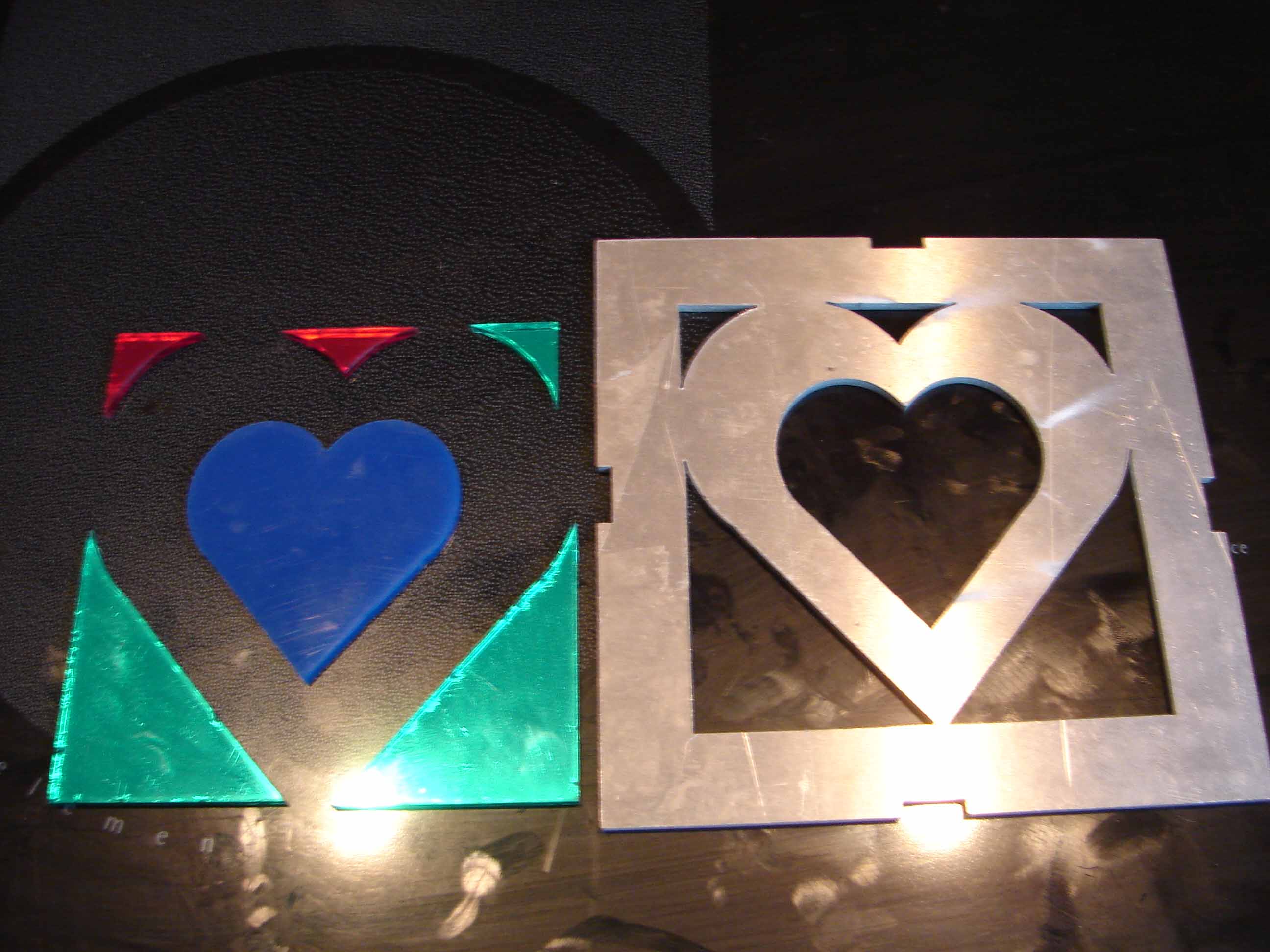

Interior pieces.

Scaling did not work for all the pieces as one file, so I had to split the master file into many little

files, one per piece, and scale each piece until I acheived a press fit-- a .02in increase in size seemed to be the

best place to start, and then manipulate in the .001in range to find the perfect fit. In some

cases, due to the odd edges of the pieces, I had to scale down rather than up. Once I found a fit for

all of the pieces, I recut them in the transparent red acrylic for the final fitting. Unfortunately

I had to start the scaling process all over again, as the reflective acrylic used for prototyping

cut differently than the transparent acrylic. Ack! Another problem is that the waterjet cutter

cuts a bevel edge, so the holes in the aluminum pieces aren't exactly square, which makes press fit

really really difficult. Ithink John said it's about 1mil difference per 5 mils of material.

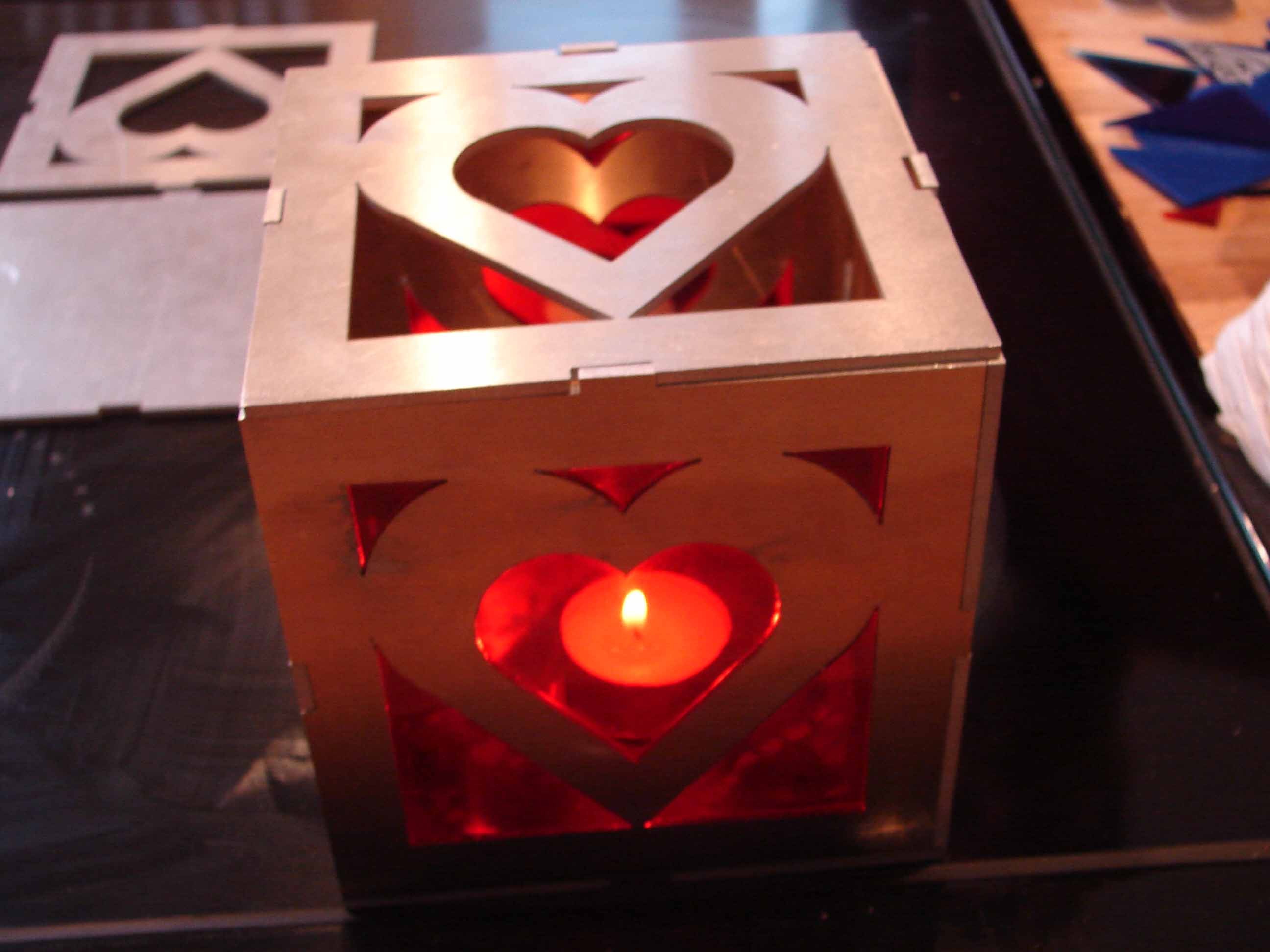

Finshed Heart Box, closeup of gaps, closeup of aluminum edge detail.

After many files and many tries, I came pretty close. If you examine the box up close you will see

little gaps here and there between the acrylic and the aluminum. Each piece should probably have

been slightly reworked at the edges in one of the software packages to make it perfect, but

time did not permit, and I like the way this looks. Already have 3 orders in for holiday presents...