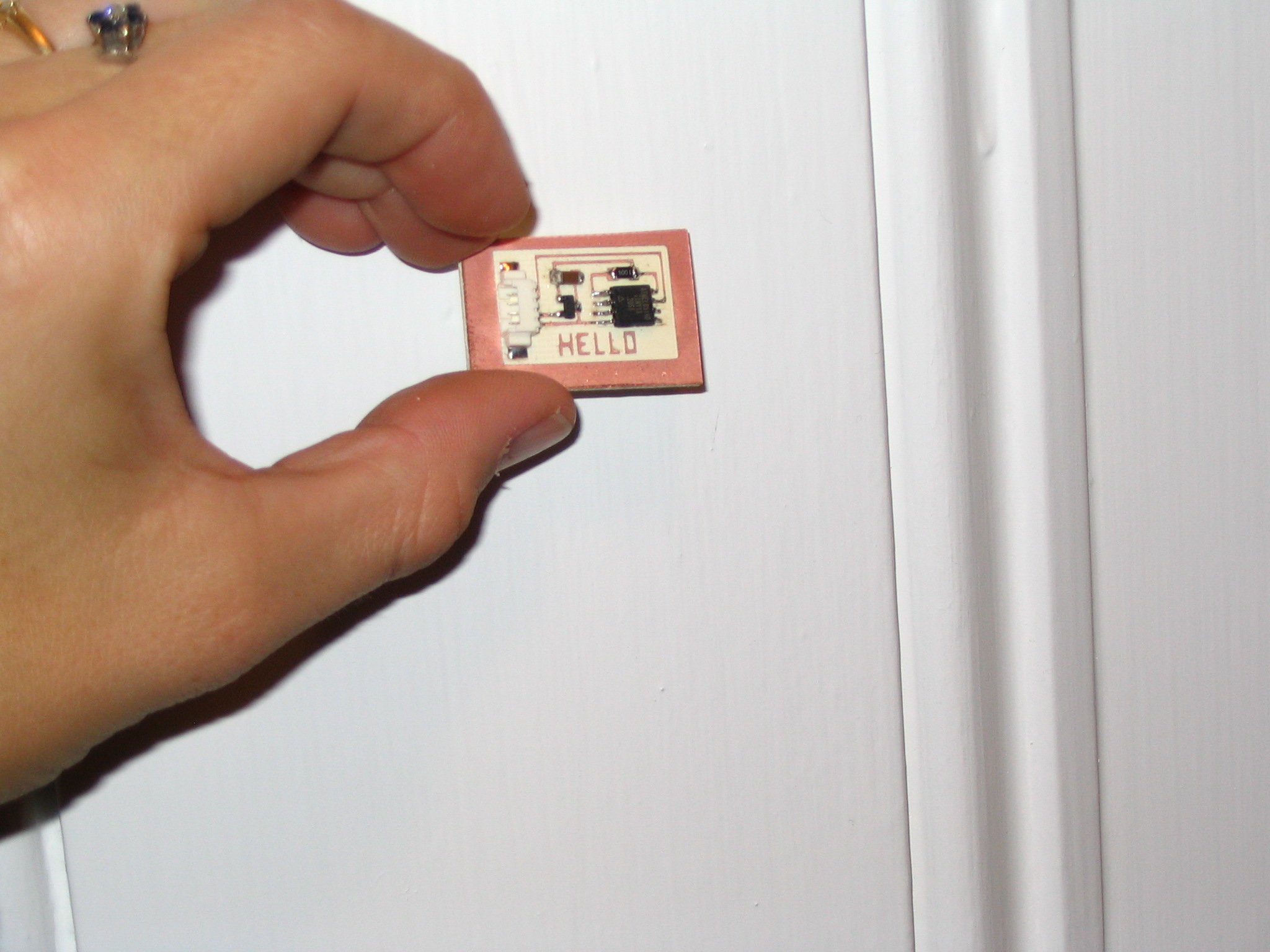

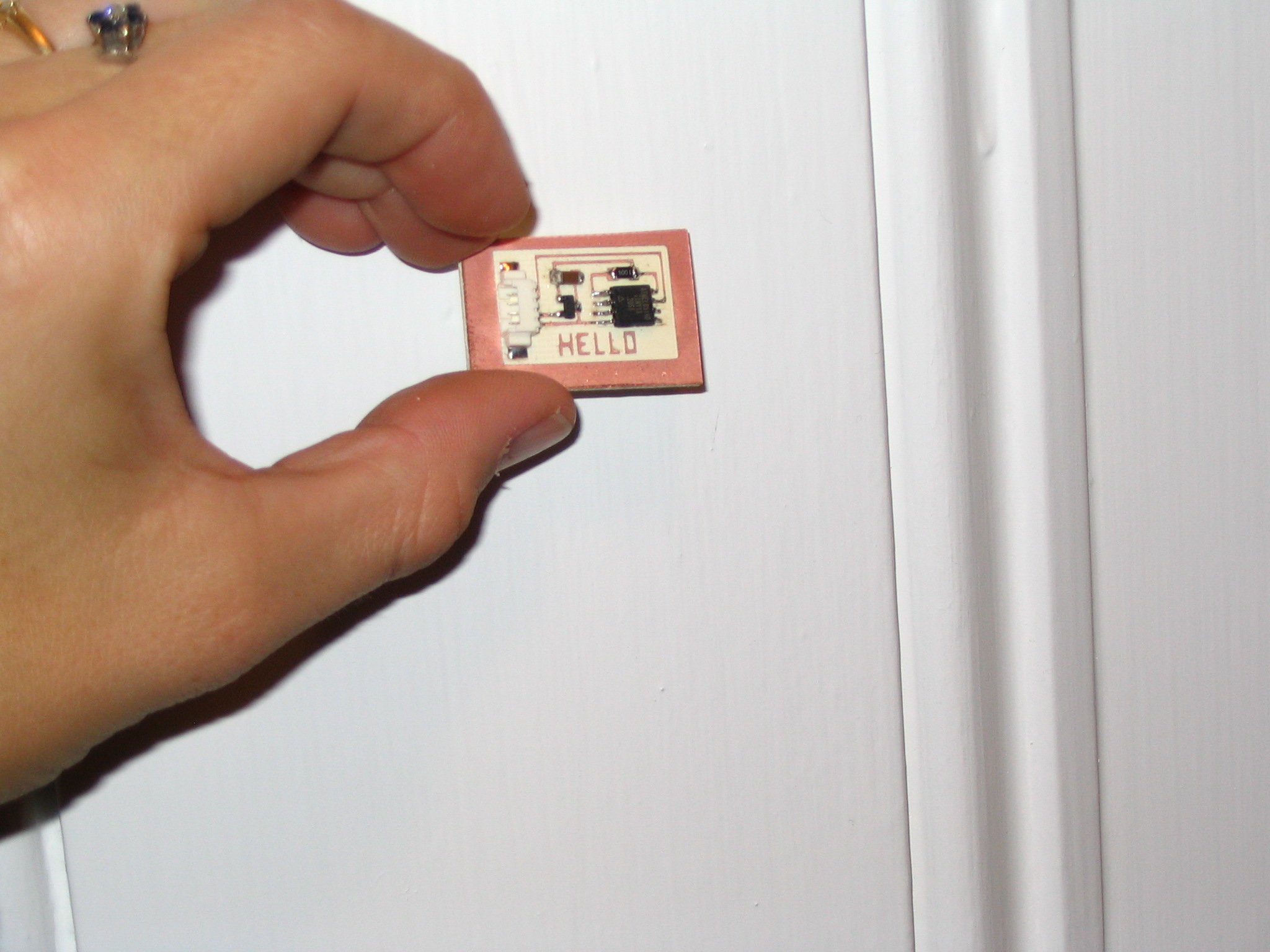

This week's assignment is to mill a "hello world" PCB on the Modela machine, then install the surface-mounted components to make it work. Here are pictures of the board schematic and layout . It took me a few tries to mill the board; the first 2 or 3 times, either the board was not flat or I was not cutting deeply enough, because the Modela did not raster all the way through the copper (I would show you a picture of these failed attempts, but with my camera they either turn out blurry and dim or blurry and entirely white with light from the flash.) After a few failed attempts, I switched to my second board and told the Modela to cut 4% deeper, and I had success! I cut out the chip with the scroll saw. Seth helped me print out a picture of the board layout, and I soldered on the required components. Amon suggested that I check all the connections between the components and leads with the multi-meter (there were some that were "suspect" because, I admit, they were a bit globby), and they were all good. The result of my work:

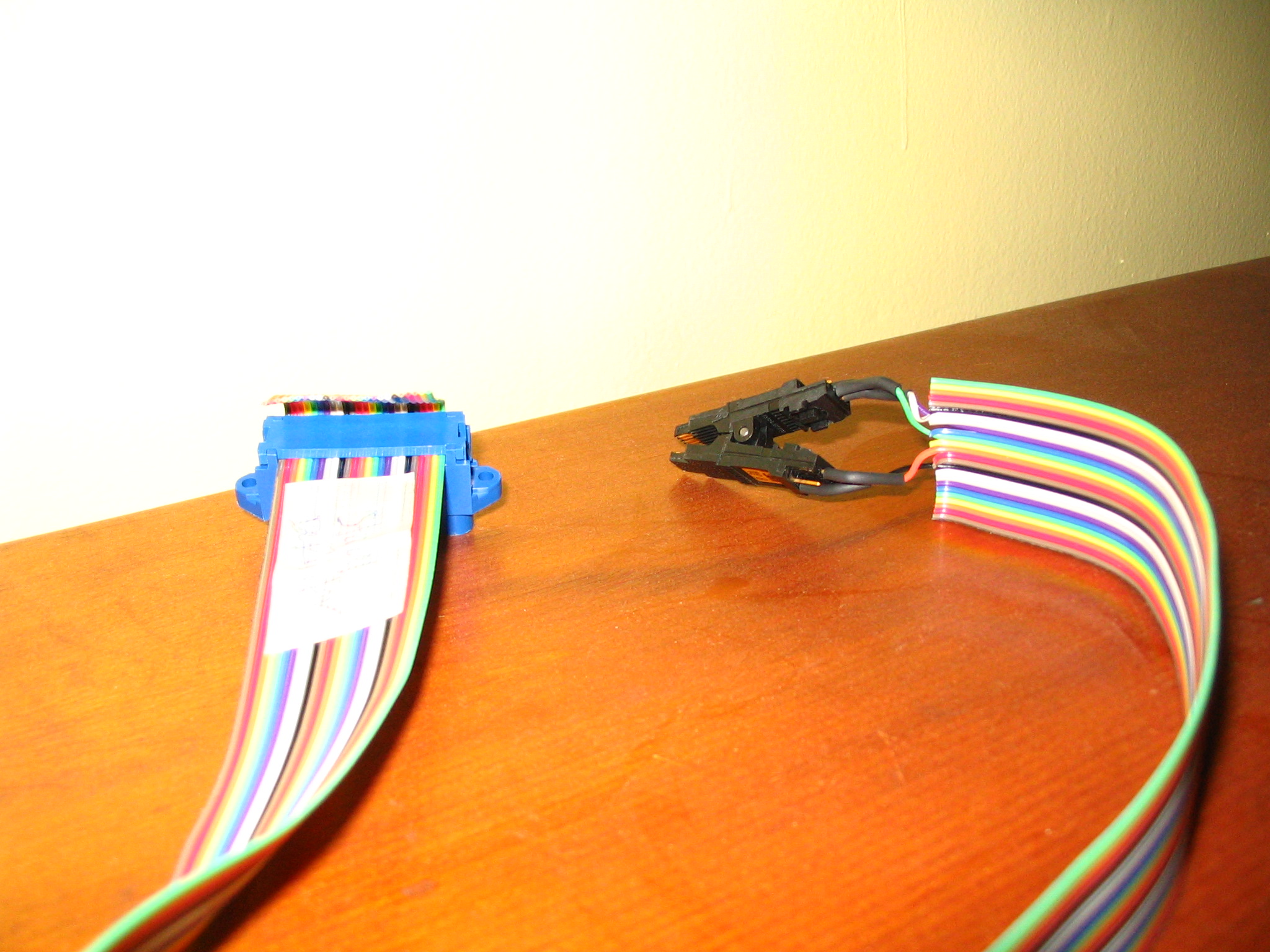

I went in to the lab today and tried to program and test my chip with the class cables. It didn't work on the first try, so I took Ken's suggestion and removed some of the solder from the connections to the microcontroller (I admit it again - they were a little globby, and may have been preventing the programming clip from closing properly). After the solder clean-up, my chip was programmed and transmitted "NILF| NILF| NILF|" or some such thing to the computer it was hooked to. Apparently (according to my classmates) that meant that the computer needed to be restarted, and if I had restarted it, it would have registered that my chip was actually sending the message "hello world." I also made my own programming cable today, and although I checked all the connections with a multimeter and they were OK, I didn't try it on my chip yet. The cable: