Having recently arrived in Boston I am still very much in the moving-in stage. With my books still in boxes I decided that shelves would be a useful thing to make. And what better material to make shelves out of then cheap and readily available cardboard?

The assignment called for press-fit construction so I ran some tests to discover the preferable method of joining two perpendicular sheets of cardboard.

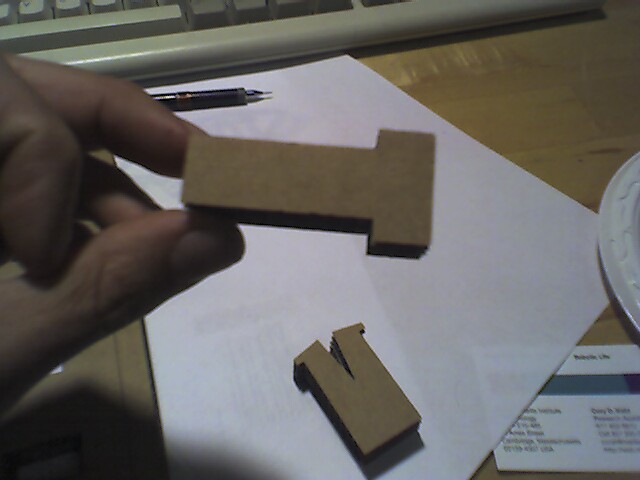

Below are my test pieces. There is a sheet of three types of female connections and two male connectors.

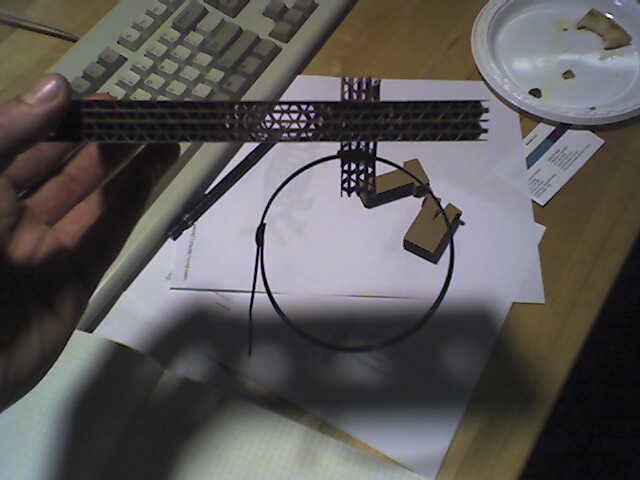

Immediately I realized the "V" shaped connector would not work due to cardboard's lack of flexibility along the axis parallel to its face. I attached the "T" shaped male connector to the "T" shaped female end and fastened a loop of strong zip-tie to the other end of the male connector.

I then filled my backpack with a healthy load of books and let it hang.

Amazingly, the first thing to break was the zip-tie, not the cardboard. I was satisfied that the "T" connector would be sufficient to hold the amount of weight I expect to put on my shelves.

Though my shelf construction would function as completely press-fit I found that gluing the shelf segments together significantly increased their ability to support weight. Here is a shot of a fully loaded shelf.

And here is the final product with some stylized shelves.

And some detail on the "T" joints.