Alternative Serial Connector (Prototype)

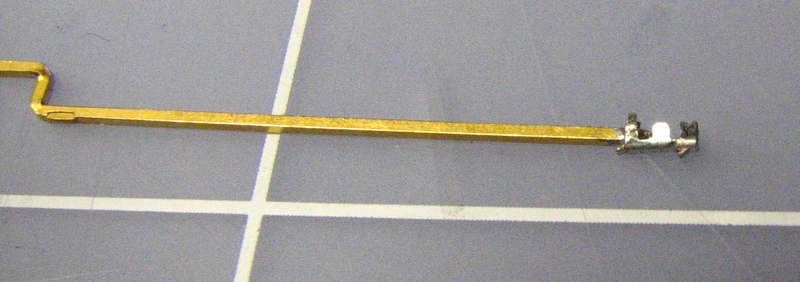

For me, the hardest part about making the cables was the serial cable's connector to the MOLEX header.

Even after my first version of the cable was done, the connection seems to be relatively fragile. Twice, when I had pulled the connector out of the board, one of the wires broke and I had to re-do the entire connector.

This is a suggestion

for an alternative way to make the connector, using stronger pins instead of the

thin wires of the cable.

This time we connect the pin to the

metal header instead of the wire:

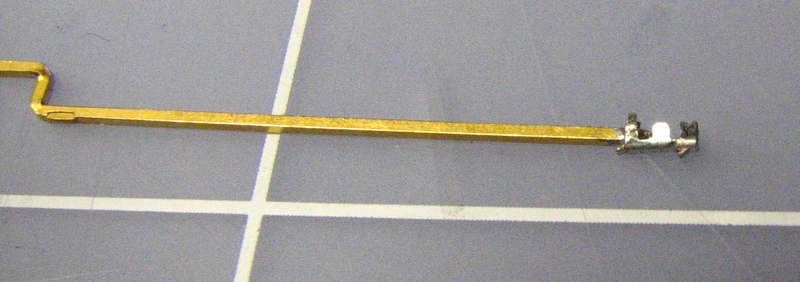

It fits!

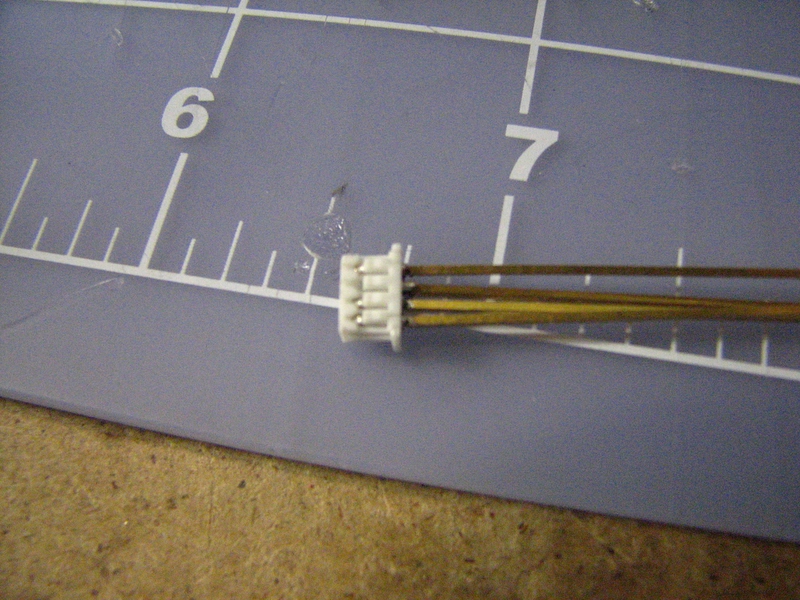

All four pins:

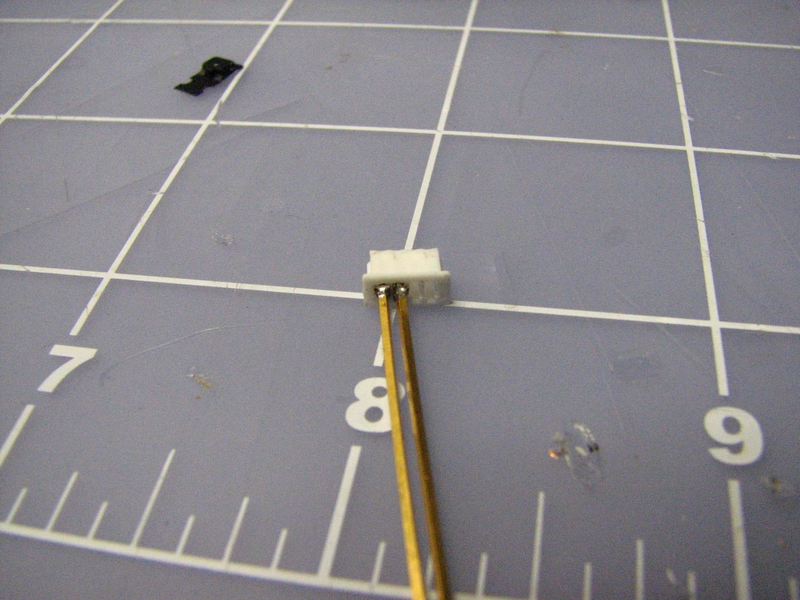

Connecting the pins to

wires:

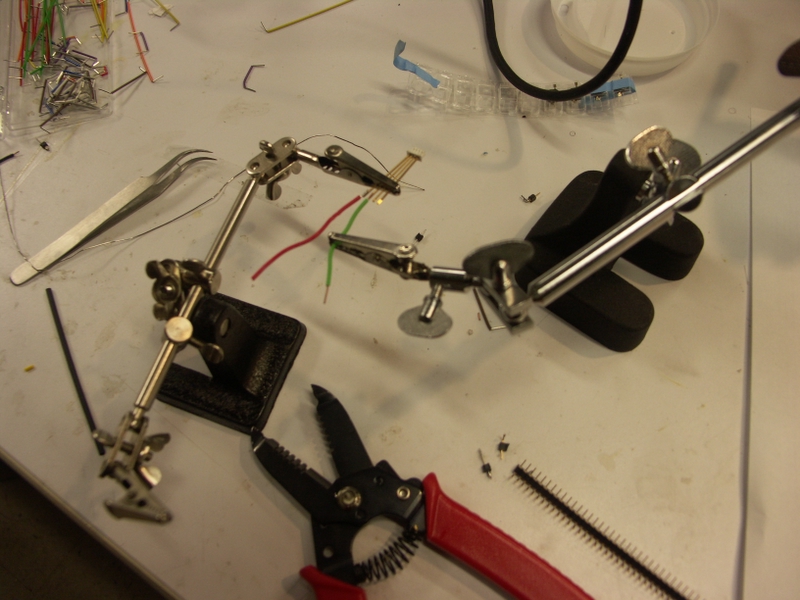

(I used the helping hands to separate the pins

from one another. It may be easier to first solder each pin to the wire, and

only at the end connect them to the plastic header)

I coated the pins with shrink wrap to prevent them from touching each other. I plan to also coat the whole group with a bigger shrink wrap, to keep them tightly together.

Result:

Notes:

This was a trial run, mostly intended to see see whether the concept works. Next time I do it, I plan to improve the process (e.g. connect the pins to the plastic header at the end and not at the beginning)

I had used the three pins that we extracted from the programming clip. I actually used 4 pins for the prototype, but we can also use just 2 of the extracted pins and cut them in half.

I plan to also coat the whole group with a bigger shrink wrap, to keep them tightly together.

Testing cable:

For testing purposes, I made a cable that has a serial connector on each

side. One side connects to the computer, as usual, and the other side for

testing different types of connectors.

The prototype connects to the cable with a serial "male" connector. The

final version of the connector can be attached to the serial cable direcrly.

Benefits of this connector:

The connector is sturdier

pressure points are not on the connection to the header anymore

unlike the wires, the pins don't deteriorate with multiple tries If anything goes wrong with one of the connections, its easy to de-solder it and re-solder it, without the need to shorten the wire.

Easy to align the orientation of the metal headers with the specific wires - we can turn the pins around any way we want.

I also think that its possible to take them out of the plastic header (by dismantling it with cutters) and re-insert them into another header (I'm going to try this soon anyways because I think I damaged my plastic header)