Assignment #2:

Make a press-fit structure

Back to main page

This

time I really tried to document my process.

Phase 1:

Brainstorming

Thinking about what to build for this

assignment, I realized that there are several themes that I want to

incorporate into whatever I end up making:

-

It should have real functionality

and could be useful (at least for me)

-

Each unit would stand on its own

and serve a purpose, but also be scalable/expandable – like a

building block for some larger structure

-

I want to experiment with

different types of press-fit connections – some of them should be

easier to disconnect and some will be more “permanent”.

This could be useful for a more

“directed-disassembly” - if force or pressure is applied to the

structure, the designer can influence which connections will break

first.

-

I really like motion and want to

do something that incorporates some sort of circular motion into the

press-fit structure.

Phase 2: The drawing board

I think that

I'll make a Modular-Expandable-Super-Structured-Wine-Bottle-Holding-Whatchamacallit. Or in short – a

MESS.

The basic unit

will be a folding storage unit that opens up and holds 6 bottles.

These units would be stackable on each other and create a bigger

storage unit. I am wondering if I also want to physically connect

such units on the sides too – but right now I'm not sure a physical

link is necessary since they can just be placed next to each other).

This way your

friendly-neighborhood-wine-enthusiast can start building up his

collection gradually from one unit up to a whole wine cellar...

I've been working with the Open Office

draw program. As was mentioned in class, the most useful feature is

indeed the ability to add and subtract shapes in order to make more

complex ones. The whole design can be done with combinations of basic

circles, triangles, and rectangles.

Some notes to

keep in mind:

Things to look

at:

- How

should the groove be designed to allow for disassembly – how

deep, how wide?

- Should it

be easy to disconnect them by hand, or will it be done with some

tools (like a pair of pliers, etc.

And hold the

“X” beams in the desired position like this:

Materials

-

It should be sturdy enough to hold 6 bottles of wine. If the units

are going to be stacked on top of each other, things may get heavy

for the bottom one, so I'll have to see if that's feasible or if I

should add some more support.

-

I guess the final material will be acrylic. I'm pretty sure that

the “X” beams will have to be with the thickest acrylic that I

could find, but maybe other parts can be with a thinner kind.

-

I can start practicing on cardboard and tweak the structure to what

I had in mind. Experimenting with the connectors, though, will

probably have to be done with acrylic, since the type of material

will greatly affect the connectors.

Phase 3:

Experimenting with the basic shapes and materials

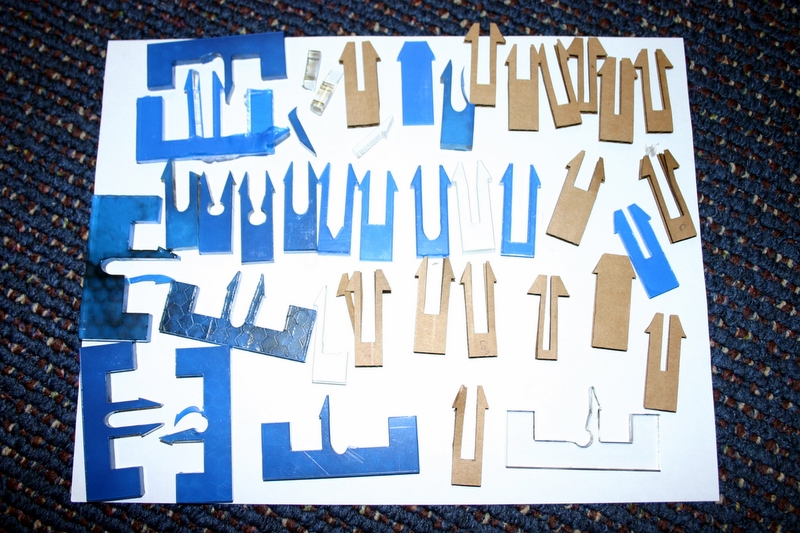

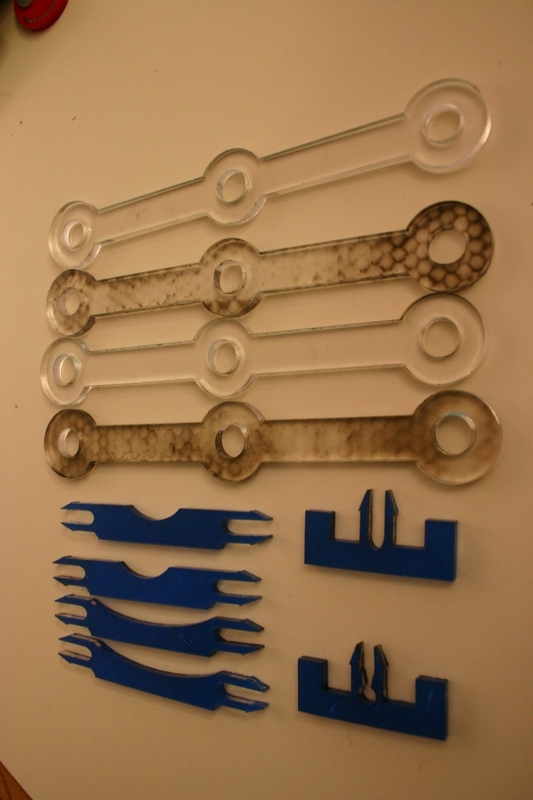

Here

are some results of experiments I did with the different materials. I started

with cardboard, and concentrated first on the shapes and features of the

connectors.

It was soon evident that cardboard is not good to test the snap connectors,

since it's too delicate.

Another thing I realized is that even if I figured out a good shape for the

connector, once I added material to it in order to get the actual shape I wanted

it to be part of, it changed the pressure points and weaknesses of the part, and

it snapped in places I hadn't foreseen originally. Most of these sensitive

points are pretty logical once you think about it, so as I advanced I was able

to better predict which parts would be more sensitive than others and try to

solve it in the design before actually building them.

I

also had many thingies like this left over from the holes of the connectors:

Any ideas what to do with these? (aside from

miniature poker chips)

I also found out that OpenOffice Draw has a neat option to export the drawing

file into a webpage, so here is my

OpenOfficee scratch pad, which also shows how the final design evolved as I

progresses with the experiments.

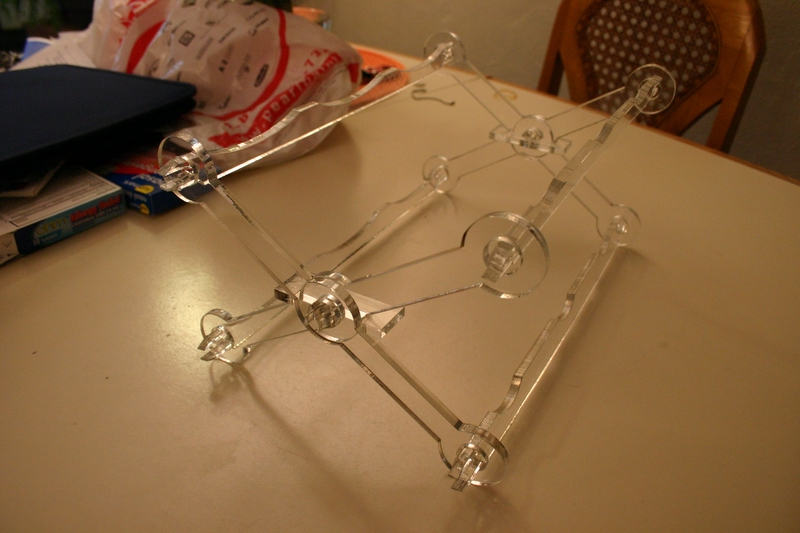

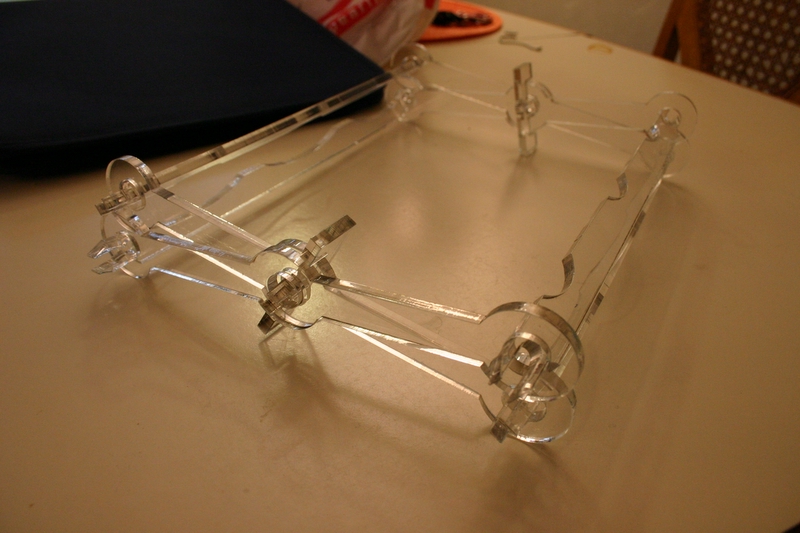

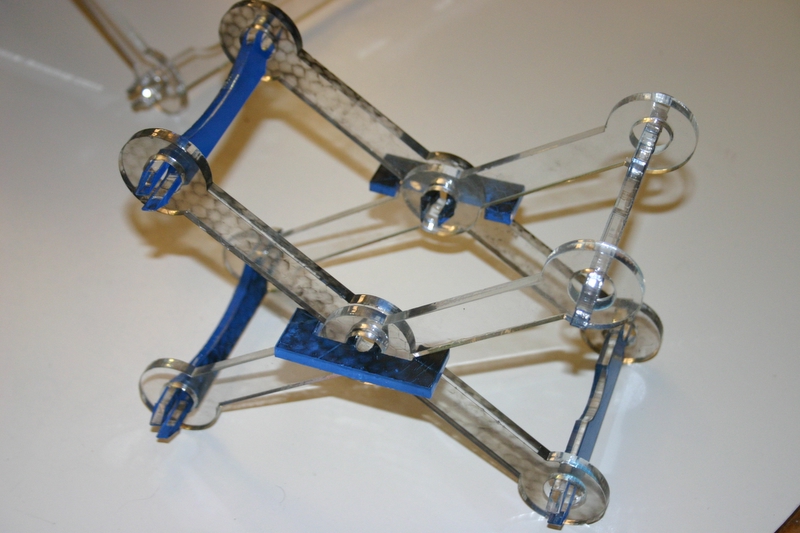

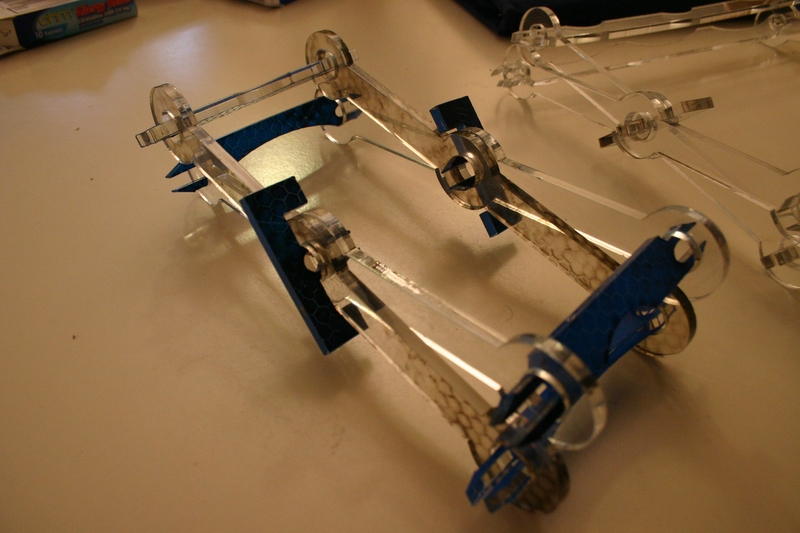

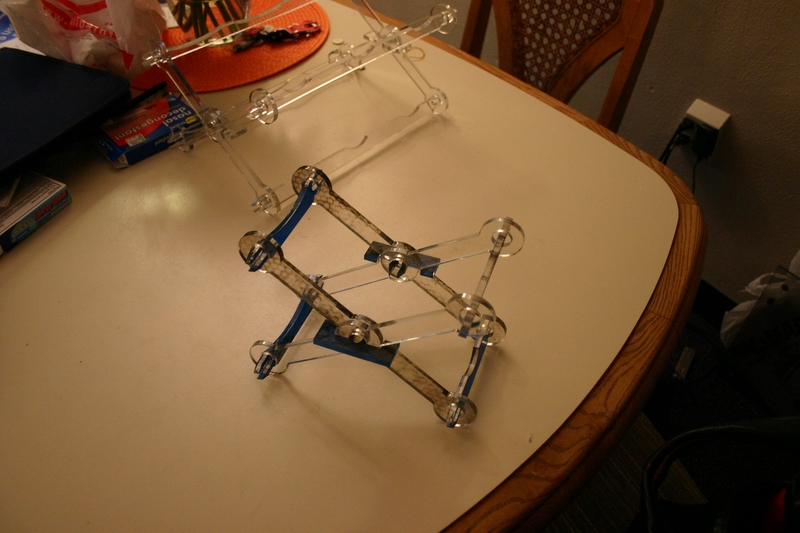

Phase 4: Assembling it

So

here's the final version. I made a 2 bottle version and a 6 bottle version. Both

seem to hold up pretty nicely under the bottle weight.

Six Bottle Holder:

Open

Folded

2

Bottle Holder

Open

Folded

Group photo:

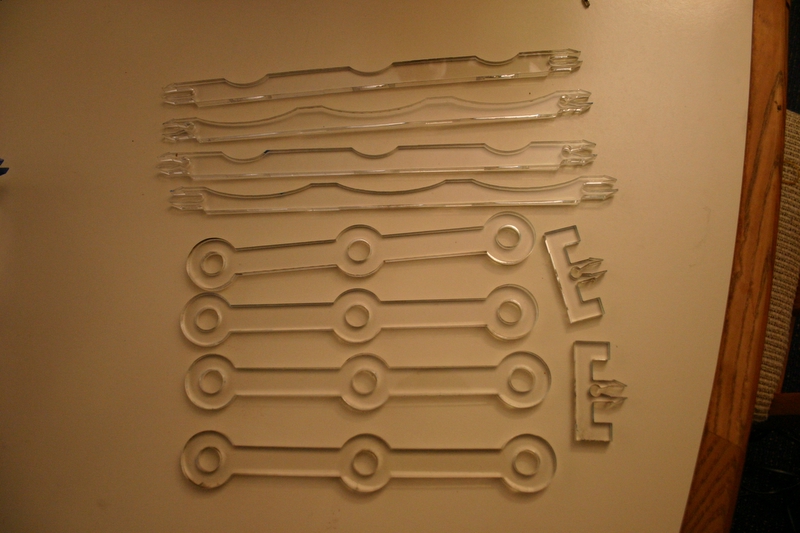

The parts:

Six Bottle Holder

Two Bottle Holder

Inter-Holder-Connectors

I

ended up doing them as stand-alone connectors. Originally the idea was that I

wanted to save material since if I hard-coded it into the arms of the holder, as

in the original design, I would have to actually manufacture several whole

devices so I can stack them up and see if my angles are correct.

By

making each connector be a standalone, its much easier to test them, and they

can be connected to the basic device and serve the same purpose. Since they can

rotate freely, they can adjust to any angle of the "X" joint, and the units will

stack up vertically.

Phase 5: It actually works!

(I

could only find 4 bottles at home..)

And

after a few sips:

Phase 6: Get more wine

Donations are welcome.