Assignment #3: Make "Hello World" circuits, cables etc.

Top: PCB Board

Bottom: Flexible board made with thin copper sheet cut on the vinyl cutter and glued on a flexible epoxy substrate (for heat dissipation).

Some notes:

When working on the vinyl cutter, there is a minimal size of sheet that is used to feed the machine. I found it useful to use it all up with several copies of the circuit, some cut with different power settings but some just for backup if something goes wrong when peeling of the unwanted material.

When soldering the PCB, I used thin double-sided tape to fix the board to the table.

When soldering the flexible circuit, I cut the epoxy film with large margins, so I was able to tape it from the top. The margins should be large enough so that the circuit won't be damaged when peeling off the tape.

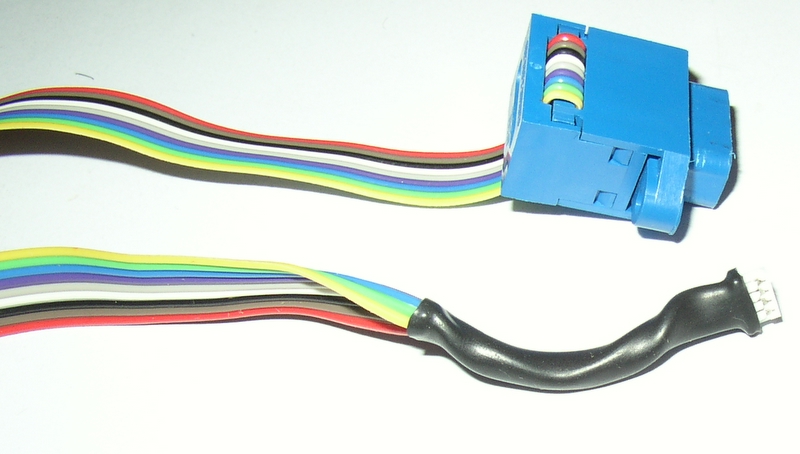

Serial Cable

Parallel Cable (Programming Cable)

Some notes

I initially had a hard time connecting the serial cable to the "female" pins for the board connector's "male" pins. After several tries, I noticed that the solder iron's head was pretty worn out. Once I replaced it with a new one things were totally different - it was much easier to create the connection - so this just showed me how much of a difference a good solder iron head can make.