Project 7: Use the waterjet

cutter to make a flexure.

I designed two things--a musical instrument and some barettes.

-- singing S --

The first thing I thought of when we were told we had to make a

flexure was the musical saw. Maybe because I had just attempted a

theremin last week and they have similar harmonics.

A regular handsaw can be made into a musical instrument by bending it

into an S-shaped flexure.

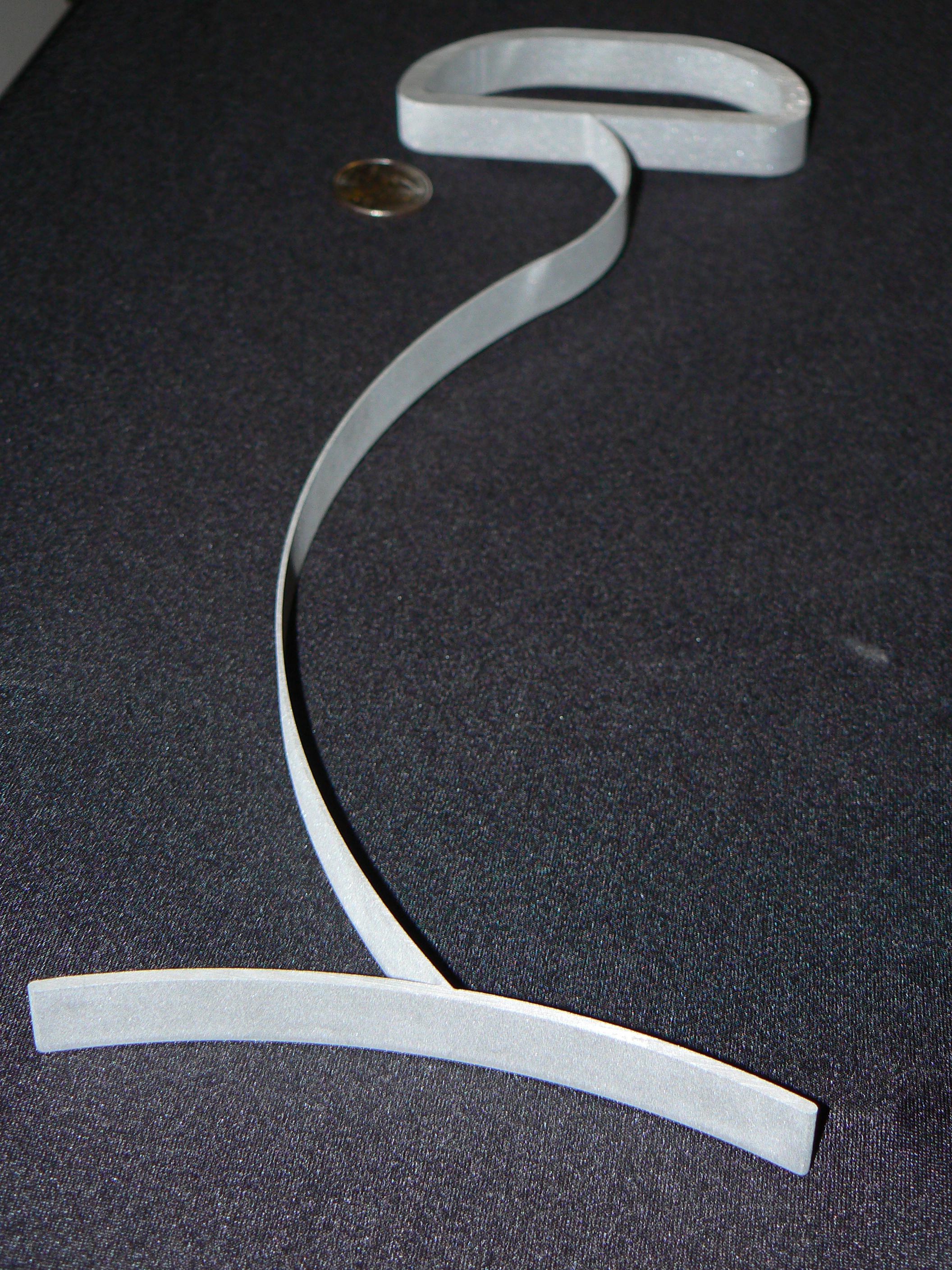

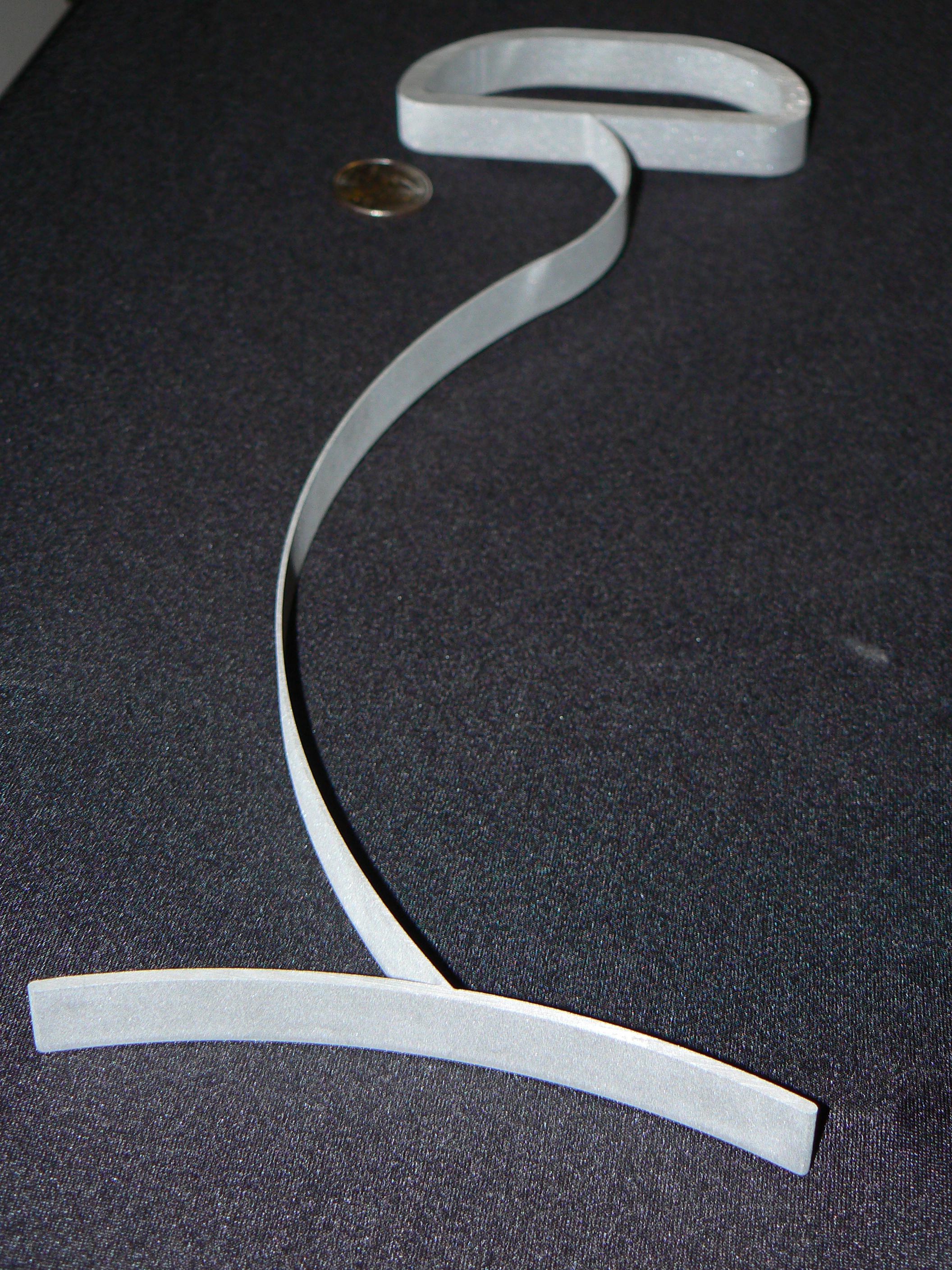

Using the musical saw as inspiration, I made a musical instrument out

of 1/2" aluminum. I wanted it to be easier to play than a musical saw,

so I designed a handle and a thigh rest into the instrument. By

pressing down on the handle or twisting it, the performer can change

the tension along the instrument and thus change the pitch.

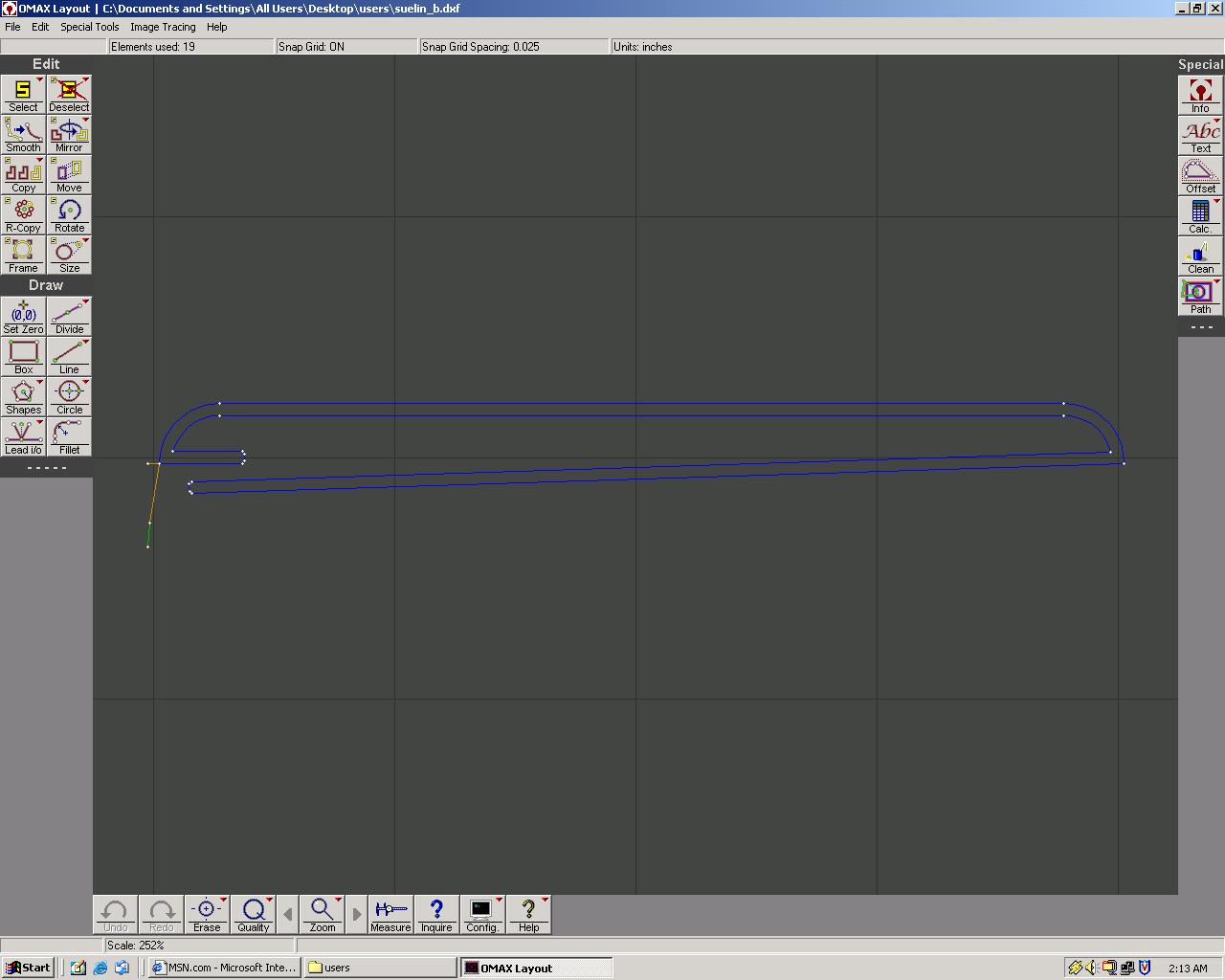

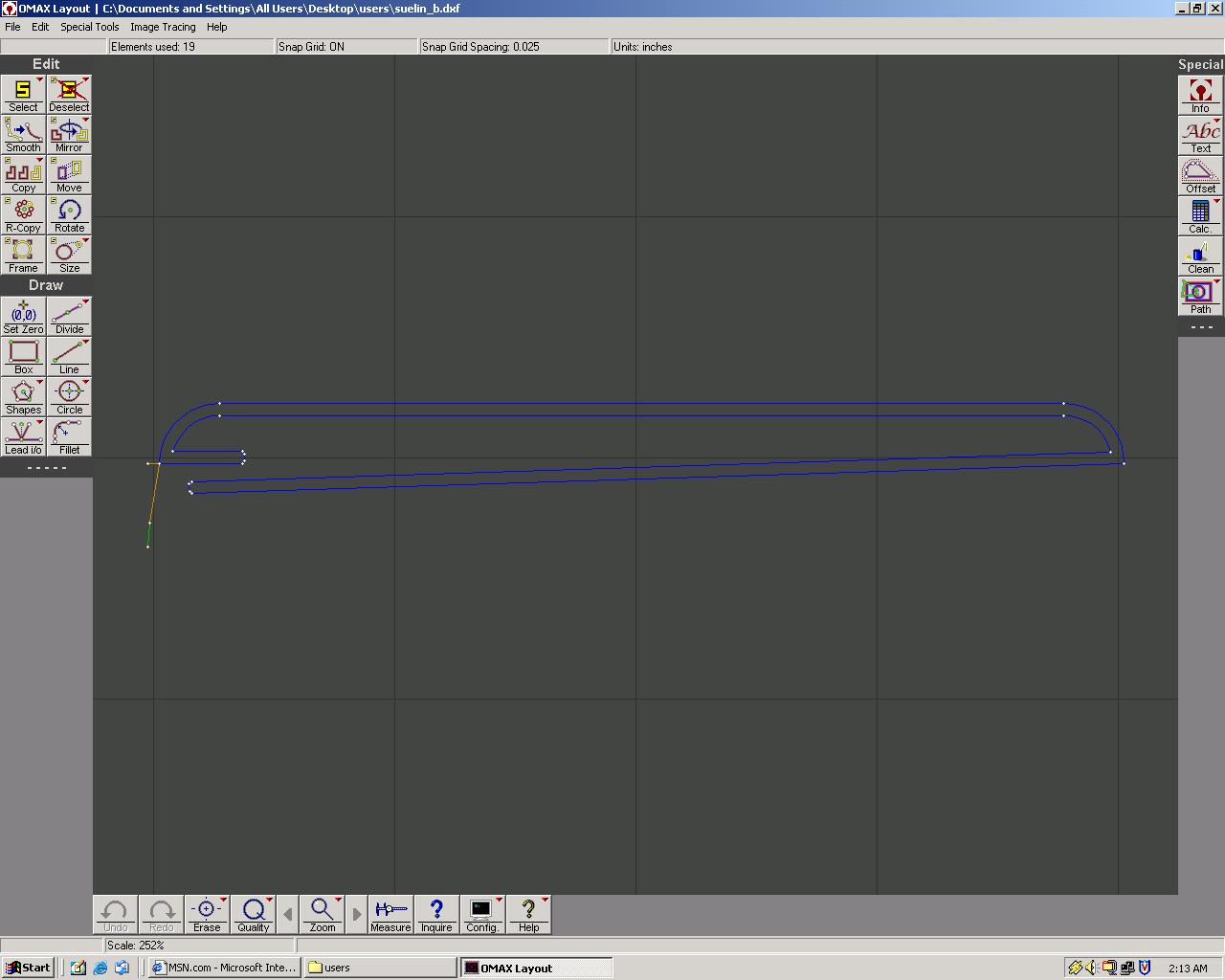

The toolpath is shown below:

The smallest width cut was 40 mils. I used a quality of 5 on the whole

thing, and made sure I clamped the metal down thoroughly.

Unfortunately, a regular musical saw is made with stainless steel,

which vibrates more nicely than aluminum. Furthermore, in my

instrument you cannot change the inflection point of the curve, which

may affect how the instrument is played.

Both my material choice as well as the size makes this not very

playable in traditional sawing ways. I feel that if I made it larger

(thicker and longer) and with stainless steel, I could bow it and

produce a sound.

As it stands, you can hit it to achieve a BONG.

-- barettes --

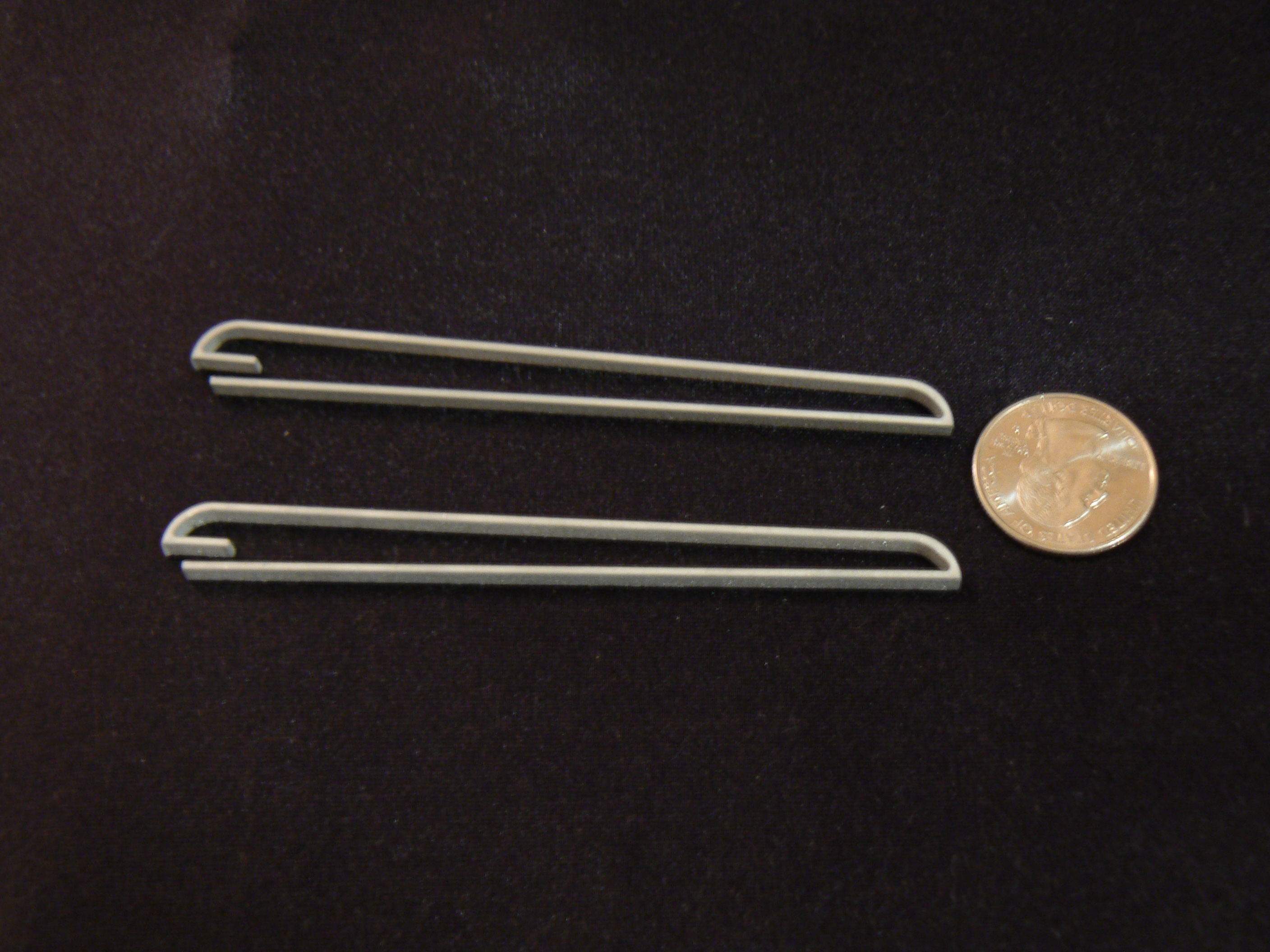

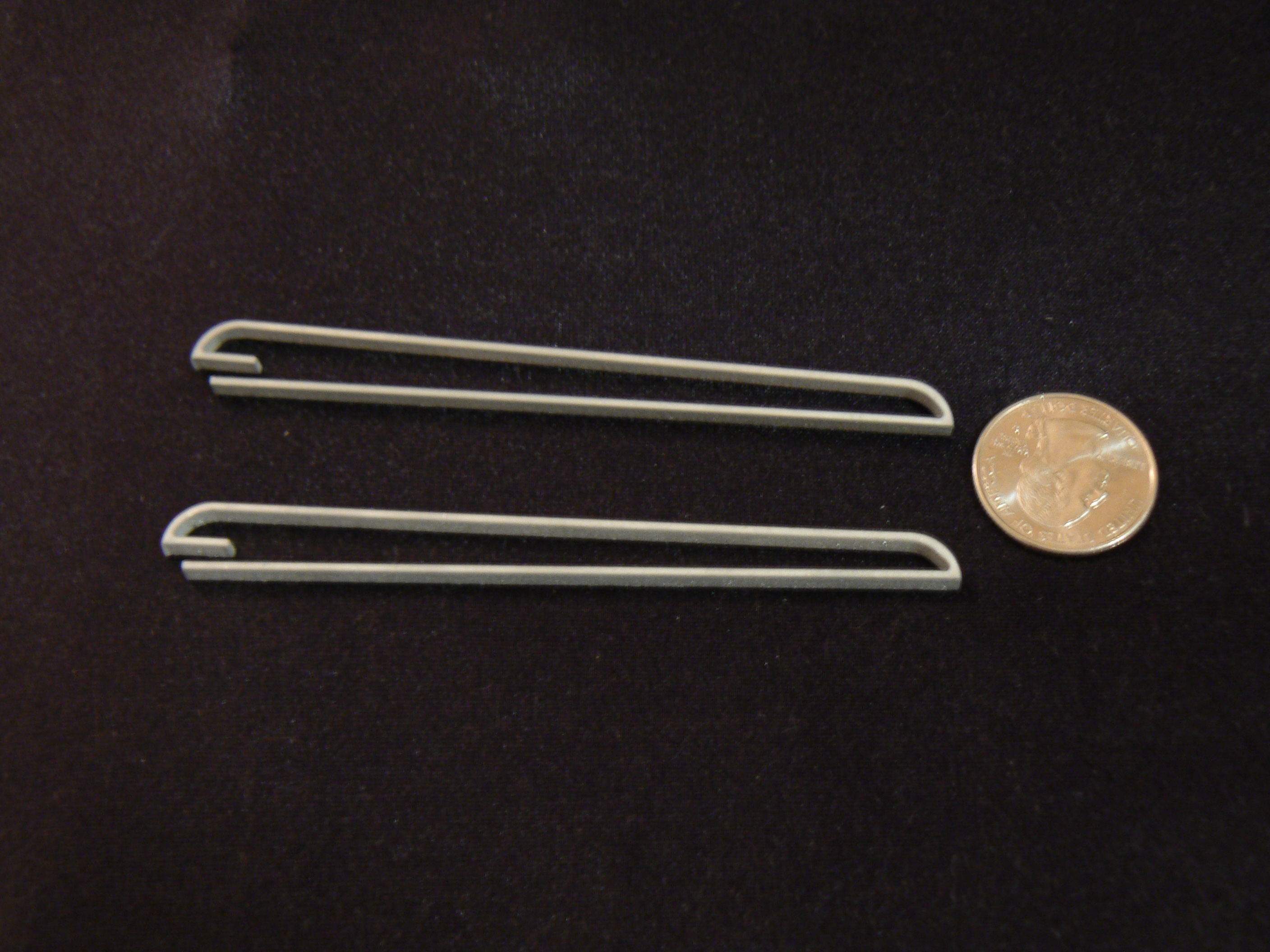

I also made some barettes, which are obvious simple flexures. I first

cut them out of 1/2" aluminum, but the aluminum is not flexible enough to

move the bottom part under the tab!

The 1/8" barettes work great though.

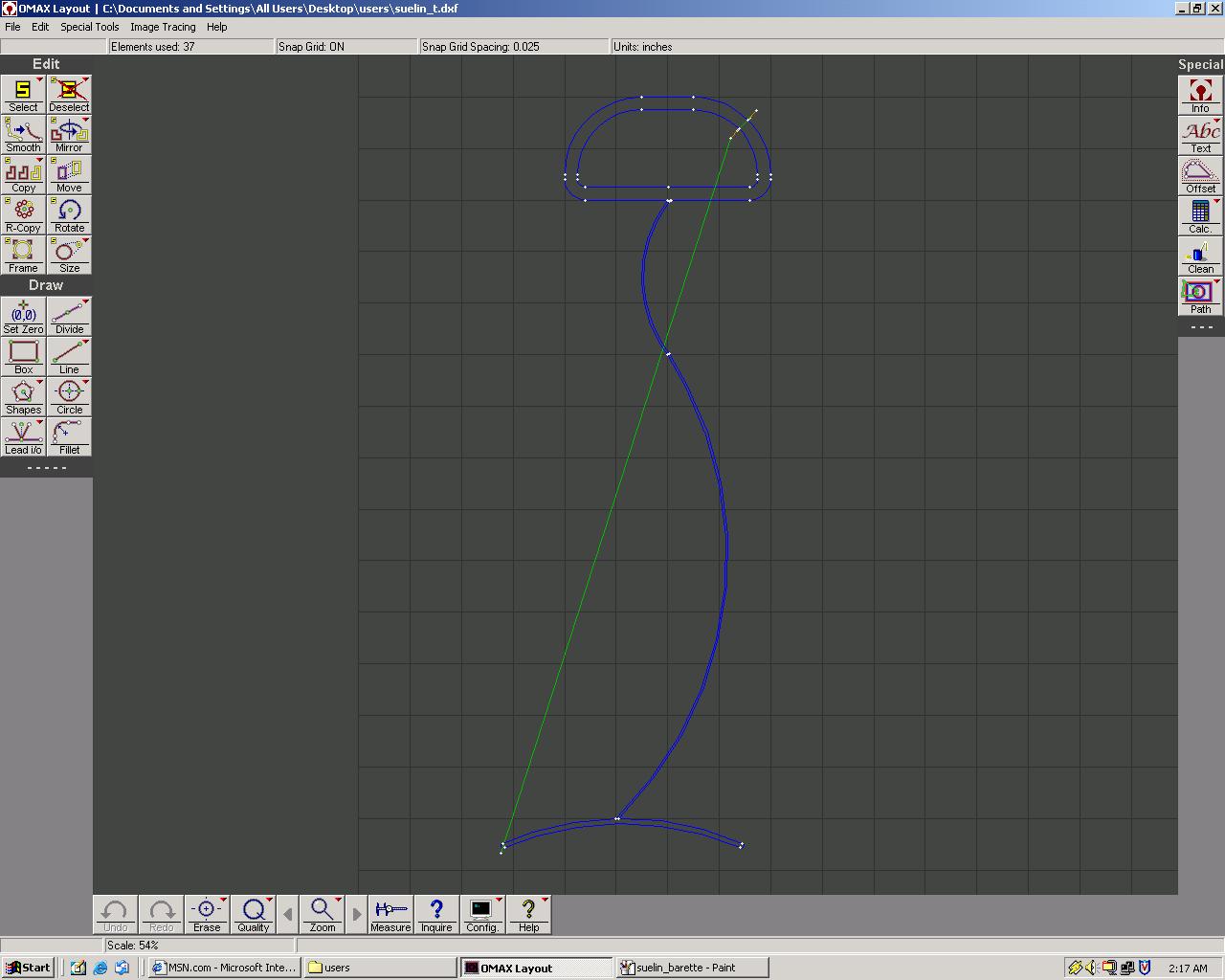

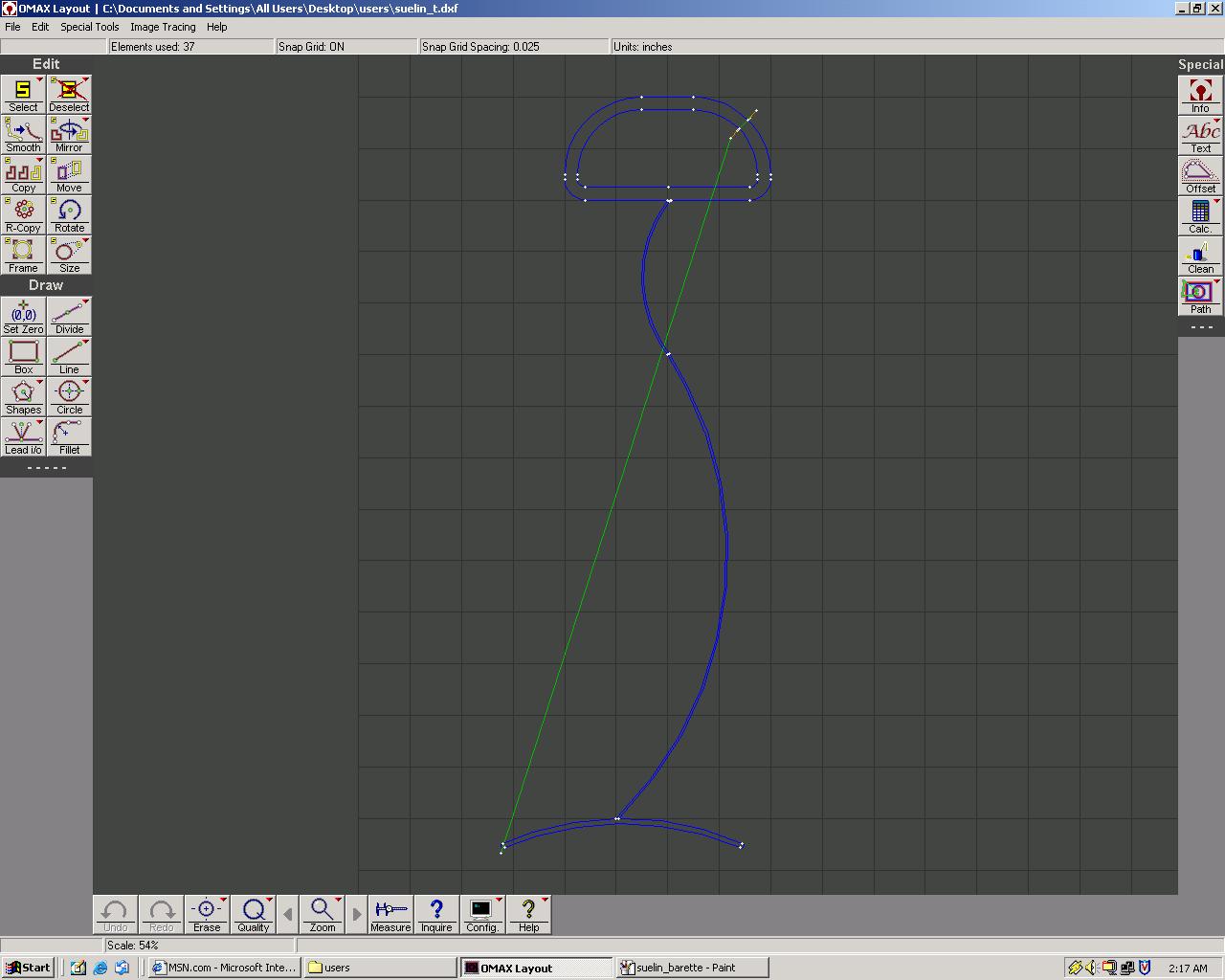

The toolpath is shown below: