Project 9: Casting/Molding. Mill

something out of wax using cad.py and the modela, make a mold out of

polyurethane, and make a plaster object.

I used Microsoft Paint to make an "F"-shaped shape with the word "art"

on it. Below is the file that I used.

I decided to use the 1/64" bit because of the small features of the

text. This made it take forEVER to render in cad.py and even longer to

mill.

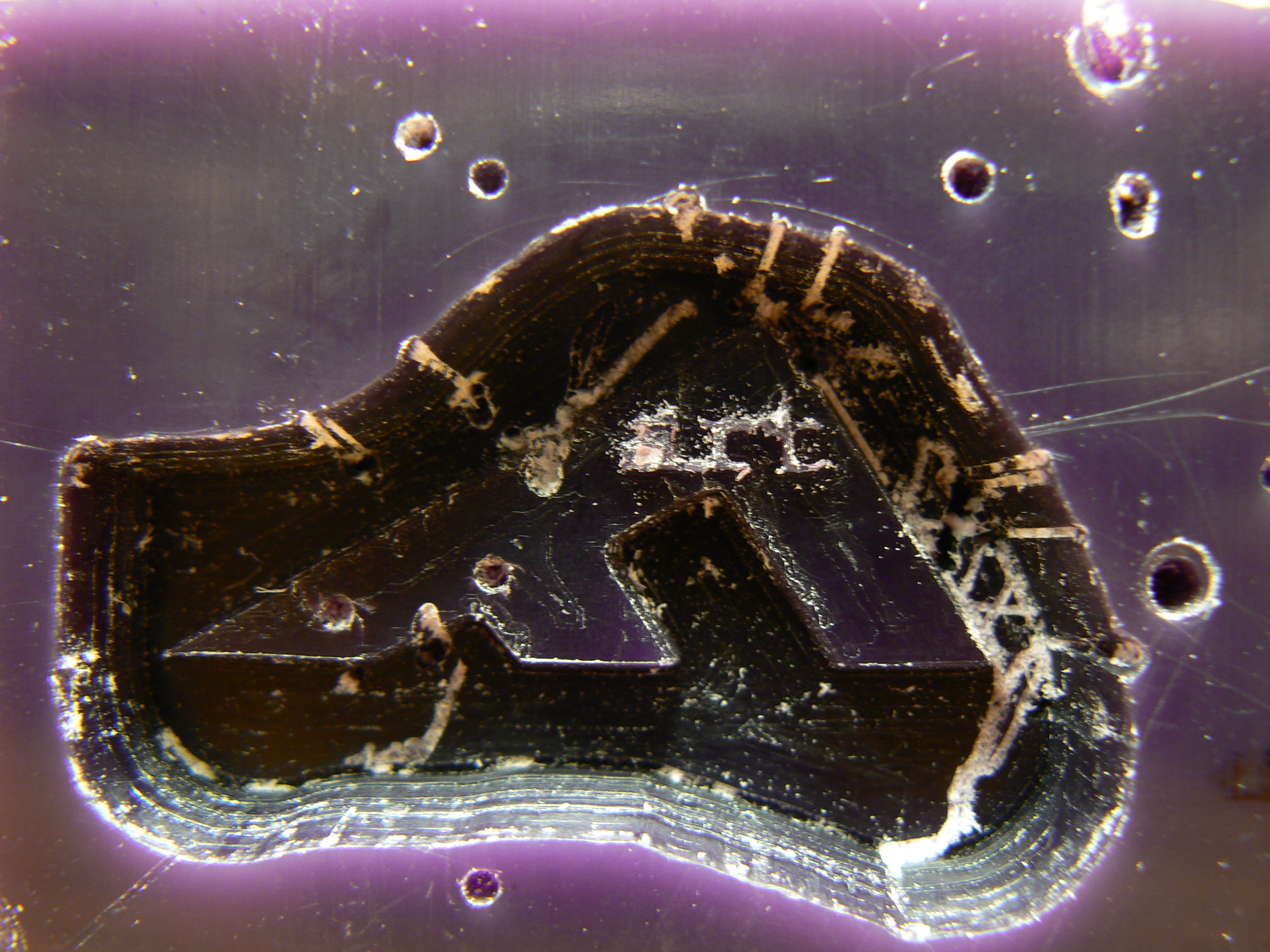

For some reason the mill decided to poke a bunch of holes in the wax

before I got to it. Who knows what that was from. It was also

really difficult to clean out all the shavings.

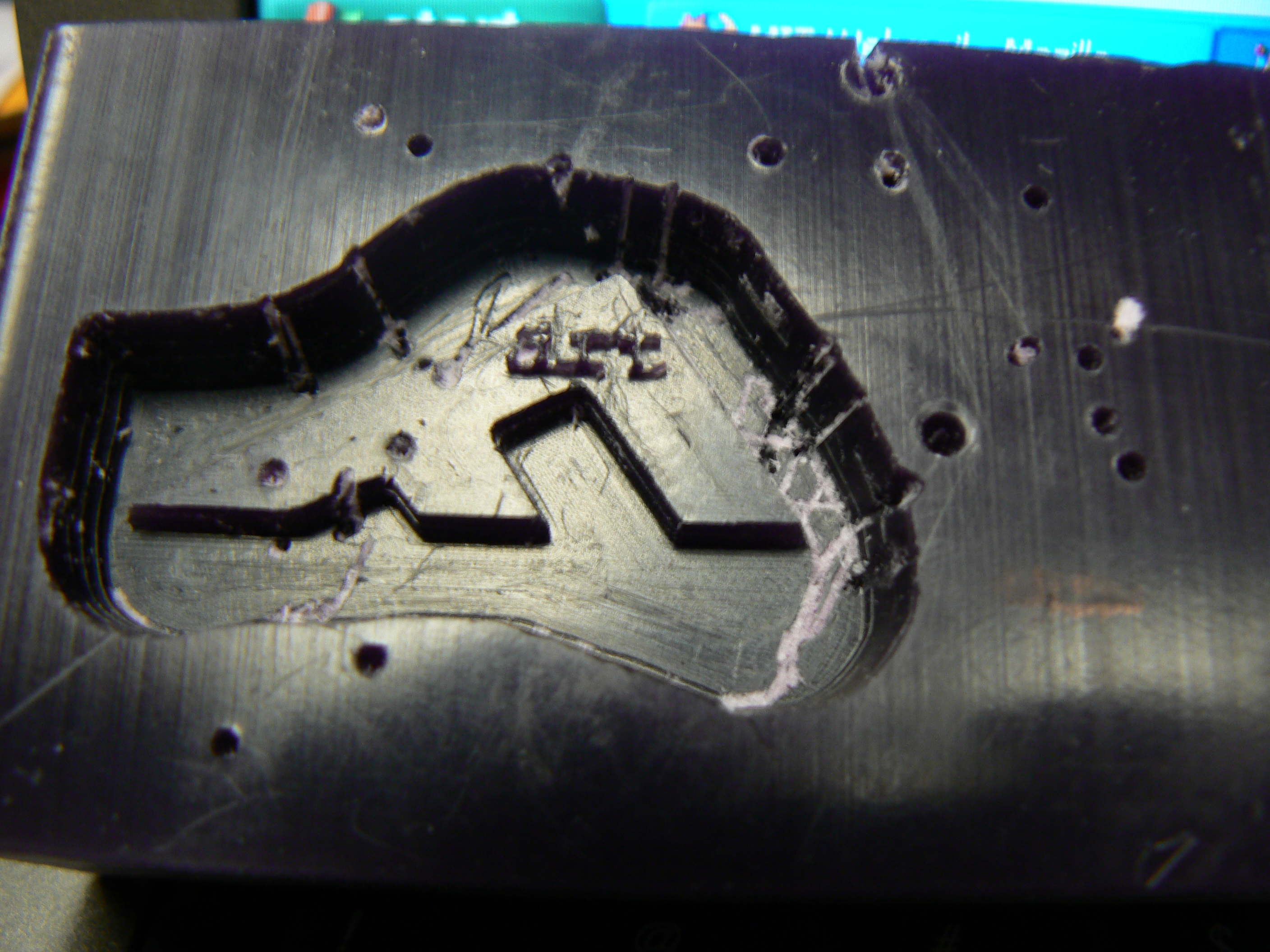

I was only able to find small amounts of polyurethane, but used them

anyway and made my mold. I left it to set for about 16 hours and tried

to demold.

so sad, it did not work!! Look at the ugly blob:

I believe this happened for two reasons.

1. I did not use demolder.

2. Regardless of this, the polyurethane is super slimy gross. I

tried again and when I remixed the two components I was shocked to

realize that part B looked really different than my first attempt

(less translucent, different consistency).

I believe this is because it needs to be stirred and since I was using

the very bottom, the dregs, the backwash of part B, it didn't quite

work to crosslink the polyurethane.