plastic cuttleryMy idea was to create nice plastic cuttlery, since the ones available are terrible in my opinion. They are probably injected moldet, but are badly designed and dont feel nice in your hands. So I copyed a proper hand made master piece by Carl Pott, the number one cuttlery manufacturer of germainy. This was a price winning serie in 1930s. Still today, every piece is handmade and every knife goes trough 96 steps of production. On top of that, I was wondering if you actually can molding such thin parts as a knife.

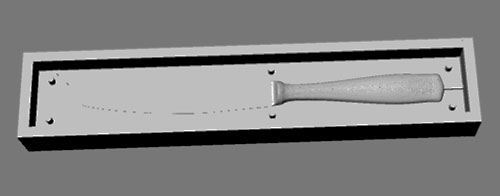

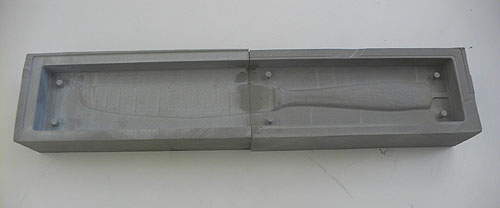

First, I started off by scanning the knife on the modela, and made a 3d negatieve mold in Rhino. One complication was that the object is to big to be milled out on the modela, so I had to cut the mold in 2.

Questions that raised during the process:

|