Week 9

Waterjet and ShopBot

Make Something Big - Bookcase

For this week's project, I thought it would be cool to make some kind of furniture using the ShopBot. After considering what I needed in my room, I decided to try to make a bookcase. I figured I would just make it press-fit and apply what we did on the Lasercutter on a bigger scale.

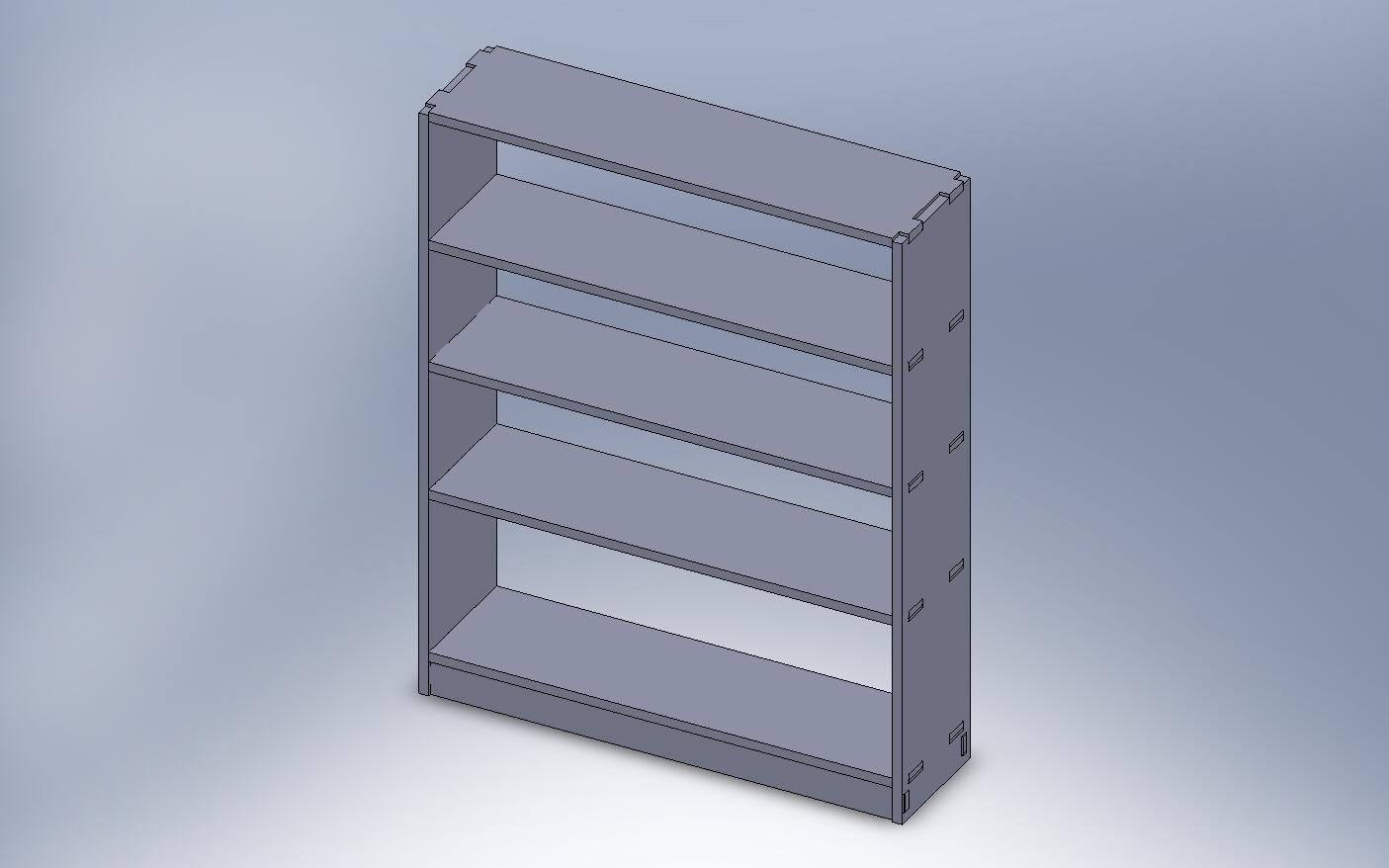

First, I designed the bookcase in Solidworks. I created a drawing of the parts in Solidworks and saved it as a DWG file. I was able to open this in the ShopBot software without any problems.

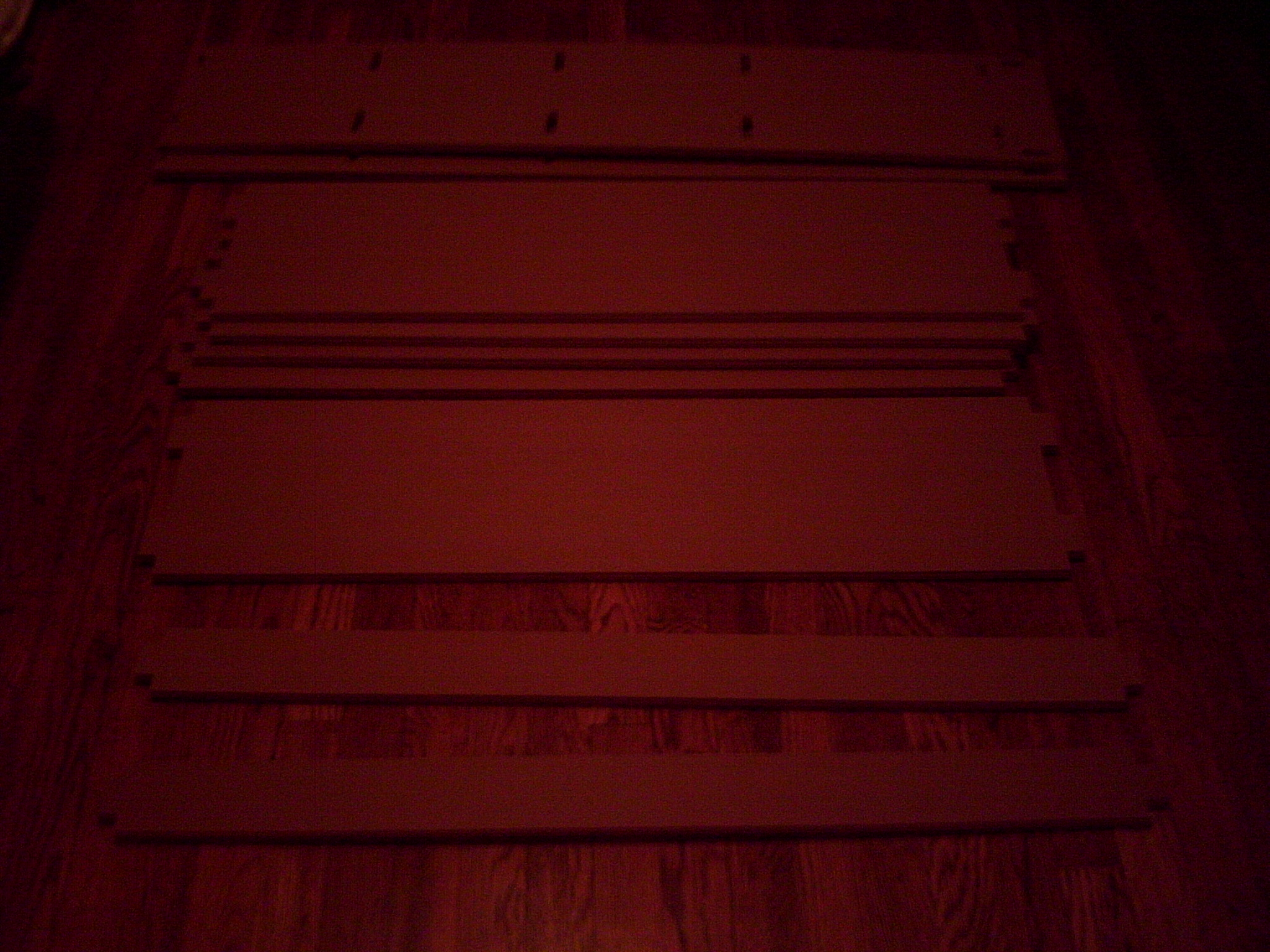

Tom helped me to use the ShopBot and I was able to cut out all of the pieces without any real issues.

The first problem I ran into was that I realized that I had forgotten to change the thickness of the boards in my Solidworks model (before I had just guessed that it would be 3/4"). I was able to change the size of the holes in the sides, but I forgot to adjust the depth of the press-fit structures on the shelves. This ended up causing my shelves to stick out a little bit at the end (see picture below).

A second problem I ran into was the way the Shopbot cut out the holes for the press-fit joints. Instead of cutting nice rectangular corners, the holes were left with sort of roundish corners. I was able to file down the corners of the shelves to put the bookcase together, but if I was doing this again from the beginning, I would have had the ShopBot cut away extra wood from the corners of the holes.

Despite these problems, I was able to assemble the bookcase, and I think it turned out pretty good. Below are pictures of the assembled bookcase and the final bookcase with some of my stuff in it.