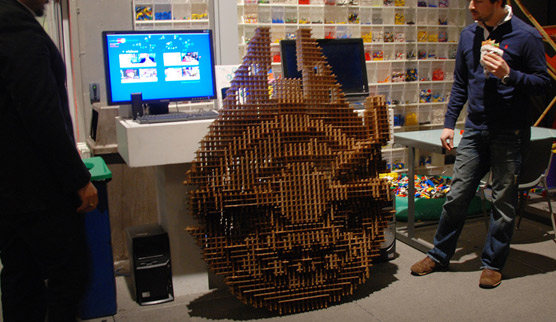

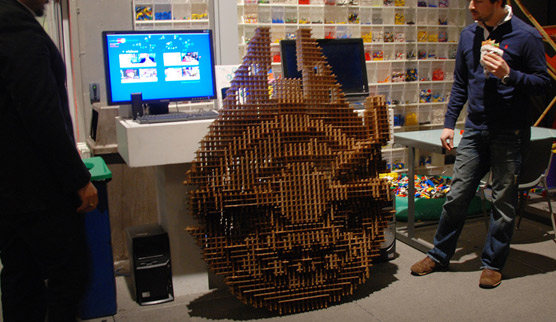

Well, here it is, MIT resources and boyhood wonder left alone for too long. To enable new types of 3d fabrication, I cooked up some cool software to process 3d models. The program, (written in python), slices a 3d model into layers that can then be cut and assembled. As an extension, I wrote an add-on that fits each layer to a grid and generates assembly instructions from the grid. Using a custom press fit construction kit and the generated instructions; you can assemble a cool looking 3d representation of the original 3d model.

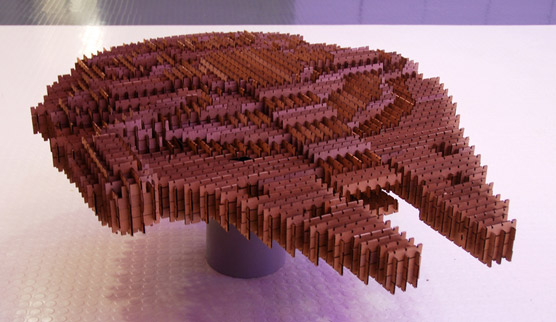

So, all this cool software magic%E2%80%A6 what should we make? %E2%80%93 Millennium Falcon. Here is a walk through the end-to-end process form CAD model, to model processing, to the final falcon. Modeling was done in Solidworks. 3d processing in Python under Linux. Manufacturing with laser cutter, good friends, good music, beer and lots of coffee. I am currently in the process of cleaning up the software and adding some examples. When finished, I will put the code up with an Instructable outlining the process.

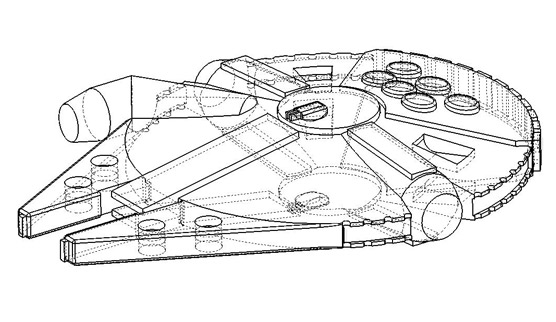

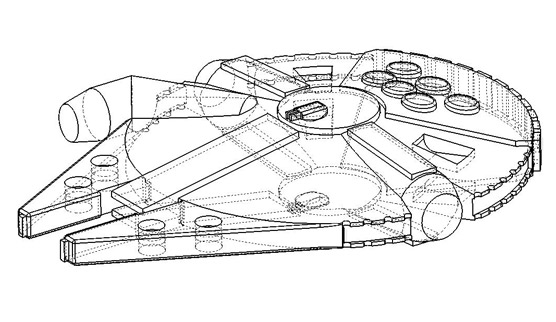

Solidwroks Model of the Falcon

Solidwroks Model of the Falcon

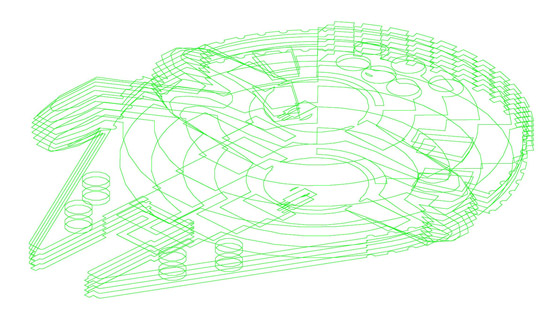

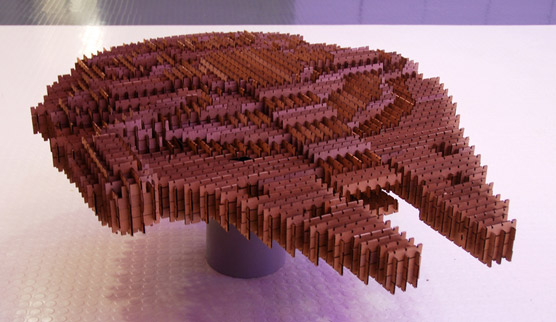

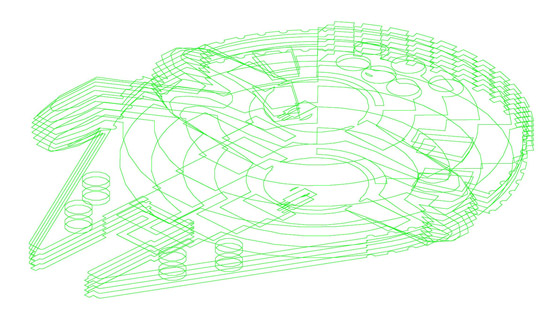

Output of 3d Slicing of the model done in the python program.

Output of 3d Slicing of the model done in the python program.

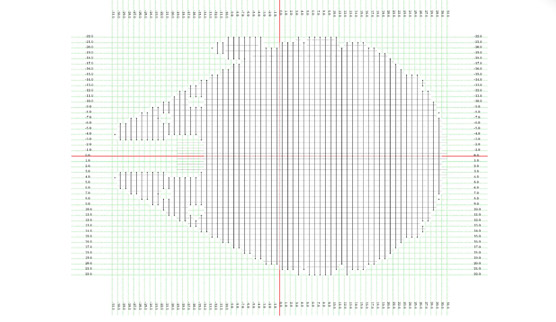

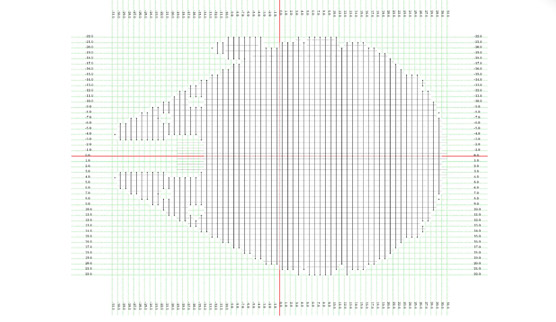

Single layer of model fit to grid - used to build giant version of falcon

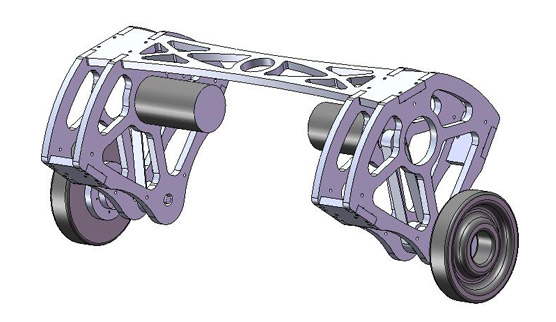

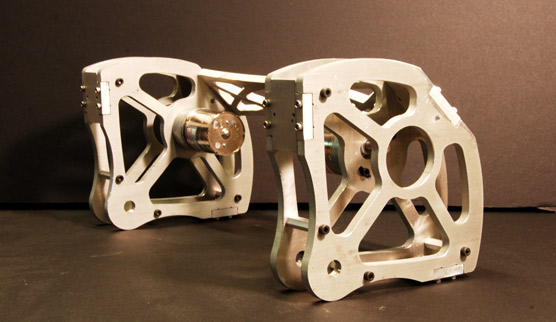

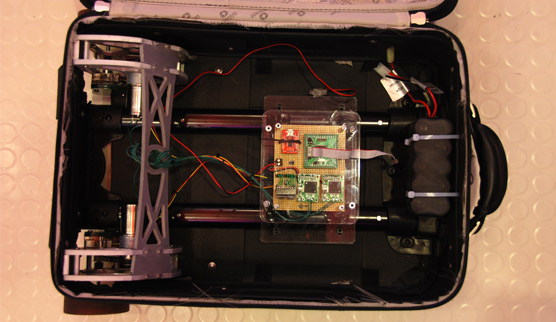

Final project 2 %E2%80%93 sort of

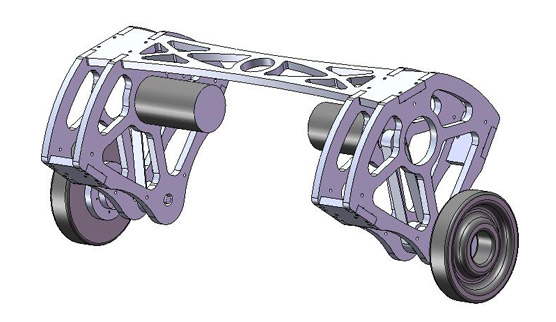

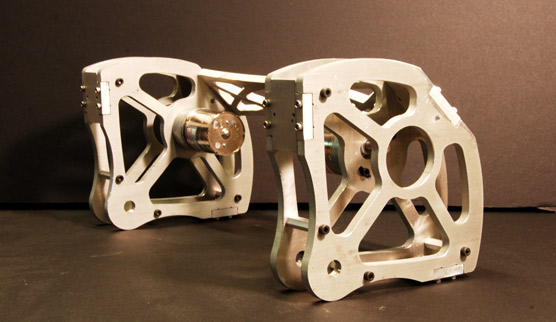

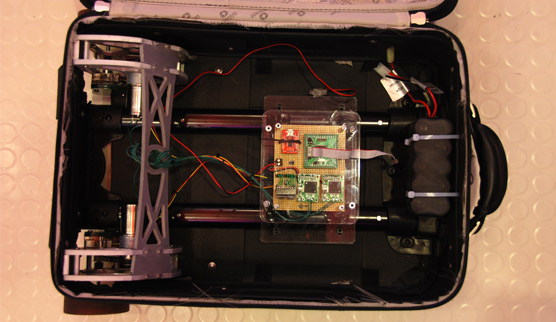

This falls into the weird ideas I have wanted to try for a while category %E2%80%93 making a suitcase that could follow you around. The project is done in terms of hardware and mechanics but, needs a good dose of state estimation and controls before zipping around in balance mode.

Components of the robot were designed and built throughout the quarter. These include the microprocessor board, motor chassis, custom cast urethane wheels, and IMU sensor. The final version should not take too much time to finish. Oh free time, where are you hiding.

So, all this cool software magic%E2%80%A6 what should we make? %E2%80%93 Millennium Falcon. Here is a walk through the end-to-end process form CAD model, to model processing, to the final falcon. Modeling was done in Solidworks. 3d processing in Python under Linux. Manufacturing with laser cutter, good friends, good music, beer and lots of coffee. I am currently in the process of cleaning up the software and adding some examples. When finished, I will put the code up with an Instructable outlining the process.

Solidwroks Model of the Falcon

Solidwroks Model of the Falcon

Output of 3d Slicing of the model done in the python program.

Output of 3d Slicing of the model done in the python program.

Single layer of model fit to grid - used to build giant version of falcon

Final project 2 %E2%80%93 sort of

This falls into the weird ideas I have wanted to try for a while category %E2%80%93 making a suitcase that could follow you around. The project is done in terms of hardware and mechanics but, needs a good dose of state estimation and controls before zipping around in balance mode.

Components of the robot were designed and built throughout the quarter. These include the microprocessor board, motor chassis, custom cast urethane wheels, and IMU sensor. The final version should not take too much time to finish. Oh free time, where are you hiding.