How to Make (Almost) Anything

Week 4: Make Something Big

Monday, October 12, 2009

This week’s assignment was to make something big using the waterjet cutter and/or ShopBot. I decided to build a big wooden clock. I’ve never attempted to build a clock before. To say the least, it was a learning experience.

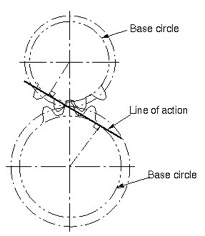

By far, the thing that I learned the most about this week was gears. I figured that before I attempted to actually design the clock, I should learn about how gears are designed. This is not nearly as simple as it sounds.

The desired involute profile is somewhat time consuming to draw by hand in a CAD program. Fortunately, I was able to find a Python script on Thingiverse which would generate DXF files from a desired module and number of teeth. Since the module is a function of the working diameter and number of teeth of a gear, I was able to choose the sizes of the gears fairly easily.

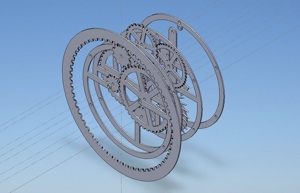

After generating the DXF files for the gears, I imported them into SolidWorks and extruded them into parts. I also made parts for the escape gear, escape lever, and pendulum. Next, I put all the parts into an assembly and arranged them in space, optimizing for functionality as well as aesthetics. This was a non-trivial task.

After the parts were cut, I cut wooden dowels to be the axles and support members, and assembled the clock. I was then dismayed to find a beautiful, yet quite nonfunctional wooden clock sitting in front of me.

I will post the SolidWorks part files here if and when I get the gears right.

Resources:

Here is a very informative document explaining the module of a gear.

This instructable contains a very useful spreadsheet for calculating clock gear train ratios.

These step-by-step instructions detail how to draw a deadbeat escapement in any CAD program.

It doesn’t work. But it’s the journey that counts, right? Right.