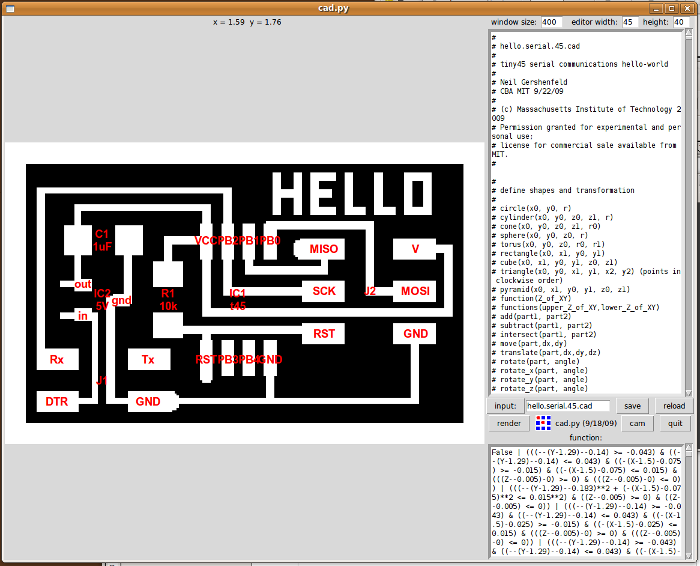

Step 1: Generate the bits

For the first step, I got cad.py running and generated the toolpaths

for the milling machine. This part is pretty easy--just follow the

instructions embedded in the cad file.

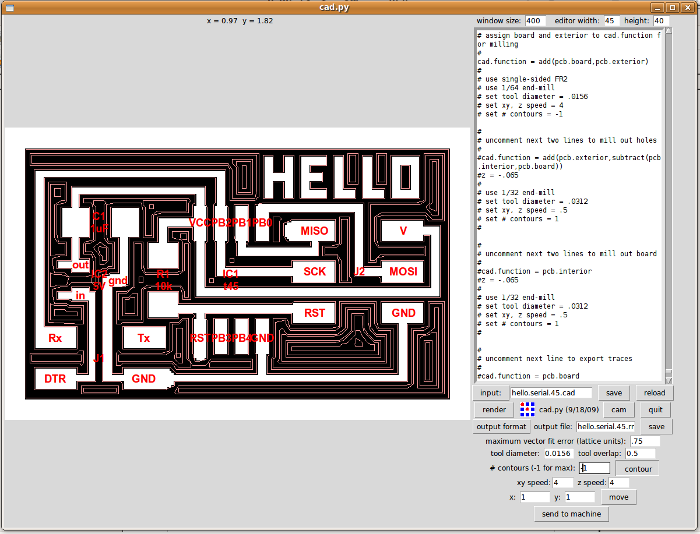

The first photo shows the board itself, without any tool paths. The

the second shows the path for complete material removal with a 1/64 inch

cutter.

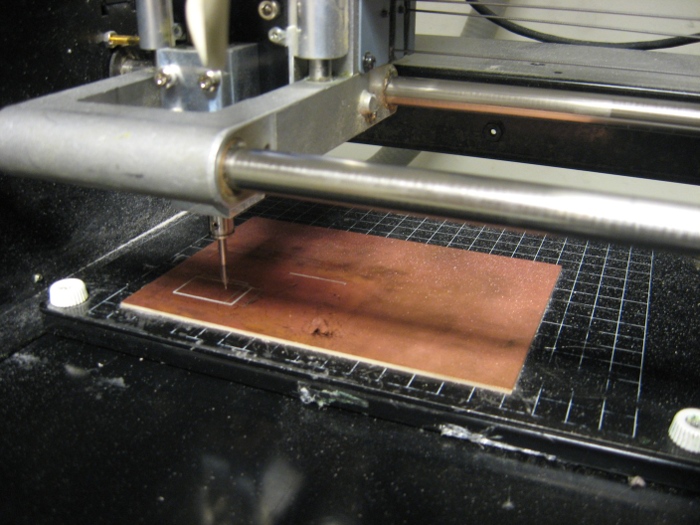

Step 2: Mill the boards

The next step was to actually mill the boards.

I stuck the raw PCB on the mill bed with double sided tape, and then

adjusted the Z axis so that the end mill just touched the board surface.

Once the machine was set up, the actual cutting took about 5 minutes

plus another minute or so to mill the board outline.

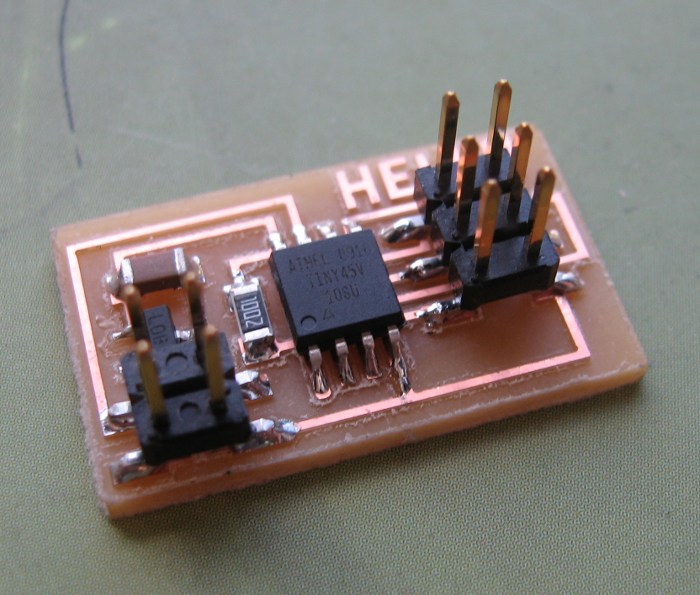

Step 3: Stuff it

With the board machined, it was time to solder. I started with the 10K

resistor next to the AVR. It looked like it would be difficult to do

that one after the AVR was soldered. After the resistor, I did the AVR,

the voltage regulator, the capacitor, and finally the two connectors.

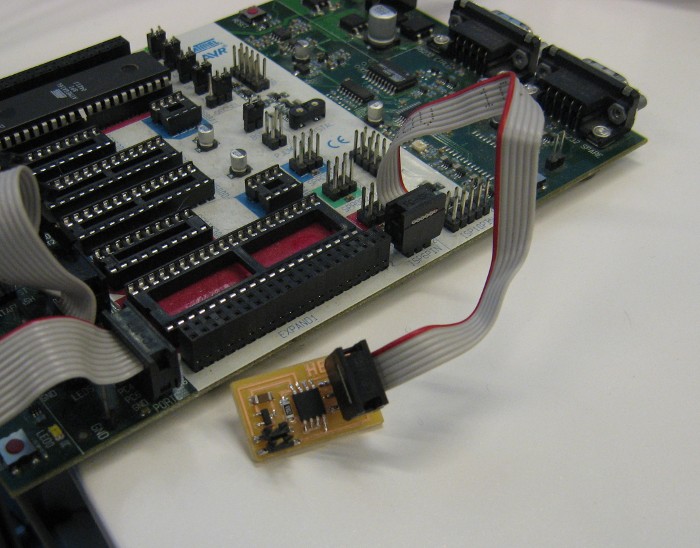

Step 4: Load the code

I used a Atmel STK500 programmer to load the code into the AVR.

The proper incantation for avrdude with this setup is:

avrdude -p t45 -P /dev/ttyUSB0 -c stk500 -U flash:w:file.hex

One cool thing about using the STK500 is that it provides power over

the 6 pin ISP connector. That means you don't also have to connect

the 4 pin connector to load the code.

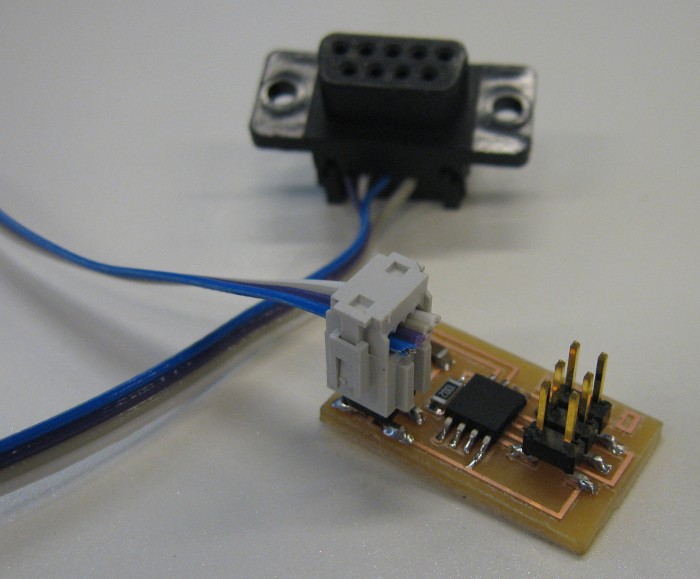

Step 5: Building the cables

I had some trouble building the serial cable using the IDC connectors.

Some of the DB9 connections were intermittent. My solution was to

solder the connections at that end and then apply a little hot glue for

strain relief. So far, this has worked well.

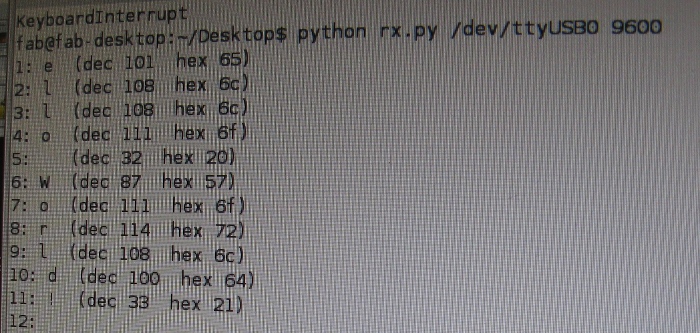

Step 6: Plug it in

With board programmed and the cable built, all that was left was to

plug the board in. DTR was set, and a happy fountain of 'Hello World!'

sprang forth!

Over and out.