( h o w . t o . m a k e ) a printed circuit board

gershon dublon

responsive environments group :: MIT media lab

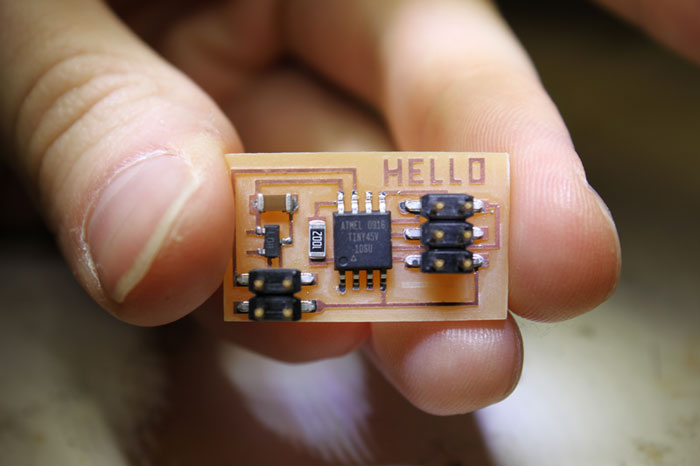

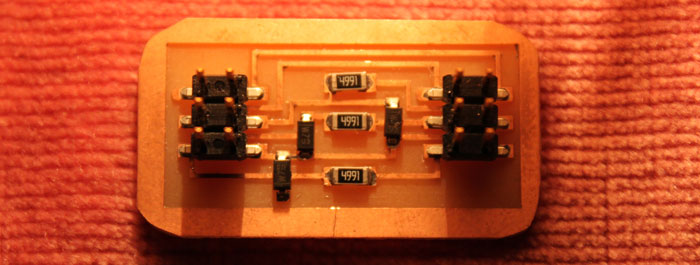

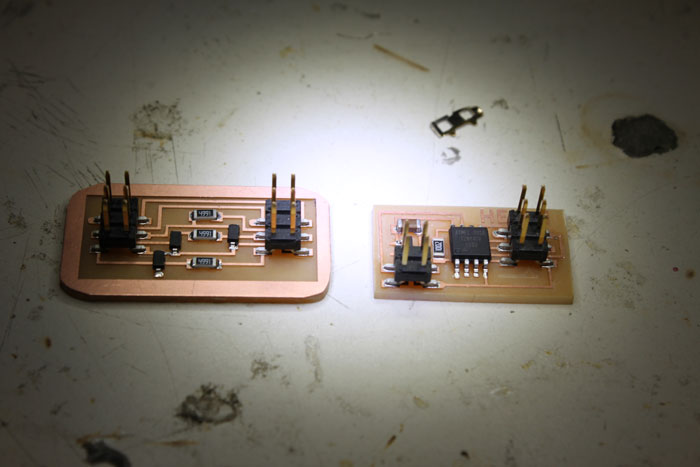

This week's assignment was to print and stuff a PCB, and then flash the onboard tiny45 microcontroller with a program that says "hello world" over a serial port. As it turns out, flashing the micro (without using a fancy commercial programmer) actually requires building a second, voltage-limiting board, and then bit-banging the micro over serial.

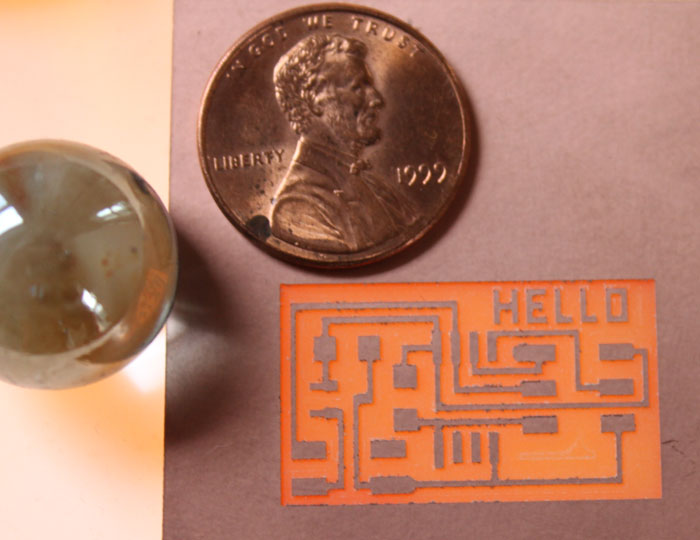

Milling circuit boards (instead of chemically etching them) sacrifices some spatial resolution for much less environmental impact. I milled the main board on the exciting new machine designed and built in-house at the Fab Lab, which required a few extra steps. I used the Modela machine for the second board; the results were pretty much the same. In both cases I used a 1/64" endmill to trace out the circuits.

I used solder paste and an oven (instead of traditional soldering) to stuff the board. The microscope in the Responsive Environments Lab was exceedingly useful for applying the paste and placing the components.

|

mas863 2009