Composite Frisbee

Composite Frisbee

Our assignment was to make a composite structure.

Pre-Fab

This was a unique assignment in that I only had one day to do it since I was going to be out of town the rest of the week.† I had prior experience with more standard aerospace composites such as fiberglass, carbon fiber, aramid, and epoxy but nothing like the range of materials we worked with this week.† I decided I was going to make a composite Frisbee.† Unfortunately, I didnít have a Frisbee sitting around and didnít have time to get one so I used what was availableÖ

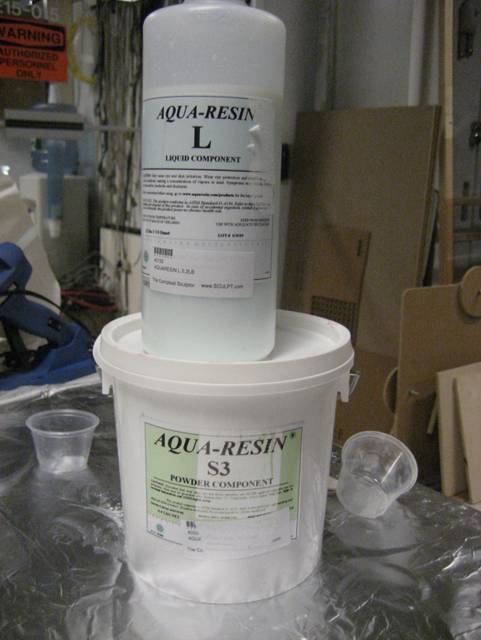

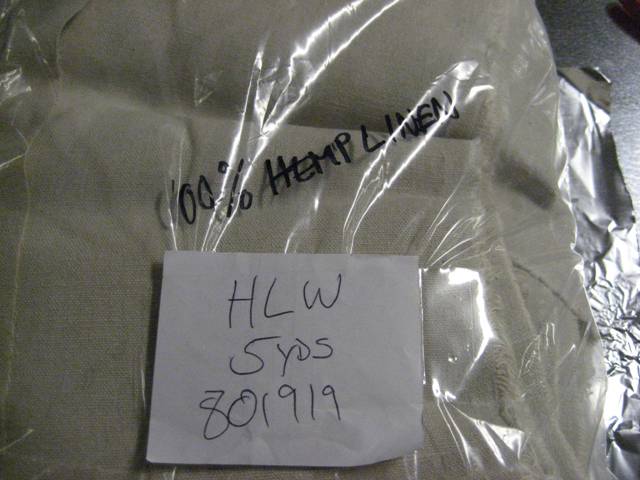

I decided to go with Aqua-resin and 100%hemp cloth for no reason at all other than I thought it would be cool to make a hemp Frisbee and the Aqua-resin was the closest resin to me.

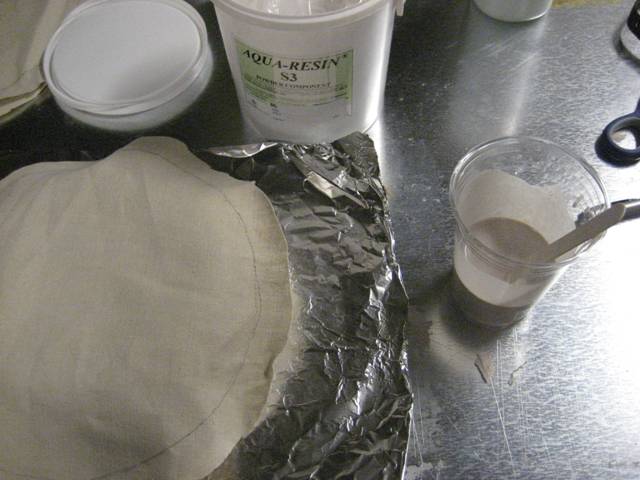

I tried to cover my mold by shrink wrapping it with some plastic I found, but that didnít seem to work to well.† I resorted to covering it in aluminum foil instead.

Fabrication

I cut 4 plies of hemp and mixed the aqua-resin in a 1.5 to 1 powder to liquid ratio.† This was to promote more flexibility in the final mold as opposed to the ceramic like consistency that aqua-resin normally gives.

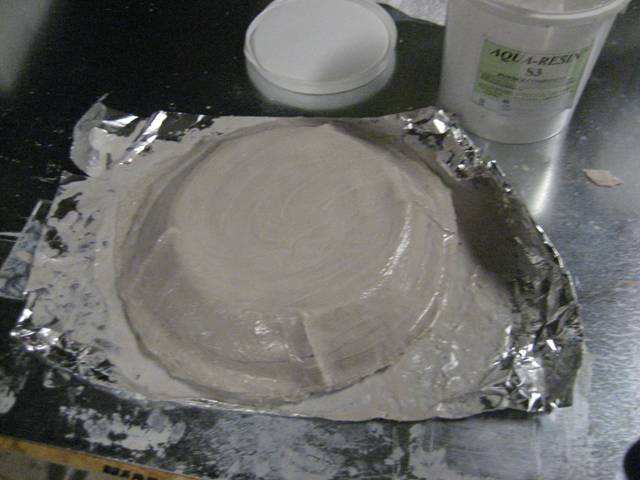

The hemp did not let the aqua-resin soak through very well so I was worried about de-lamination and had to mix up more resin than I originally thought would be needed.† I also had to cut some slits and overlap the hemp and it ended up sort of looking like a pie crustÖ

The aluminum foil worked well to make sure the Frisbee didnít stick to the mold.

The post-processing reminded me of cutting a pie crust.

It ended up pretty awesome.† Itís heavier than I expected, but strong (I can stand on it) and flies quite well!