Microntroller Programming

Microntroller Programming

Our assignment was as follows:

†† - read an AVR data sheet

†† - add a button to the serial echo hello-world board

†† - modify the serial echo assembly program to respond to the button

†† - modify the serial echo C program to respond to the button

AVR Data Sheet

Since we were working with the ATtiny44 this week, I decided to read the data sheet for that chip.† Itís 229 pages long!† And itís very confusing.† Iíve never worked with microcontrollers before, so this made me feel like I was drowning in a sea of bits and bytes without knowing which ones were helpful and which would turn my board into a pile of melted solder.† At this point, it seemed almost helpless.

PCB Fabrication

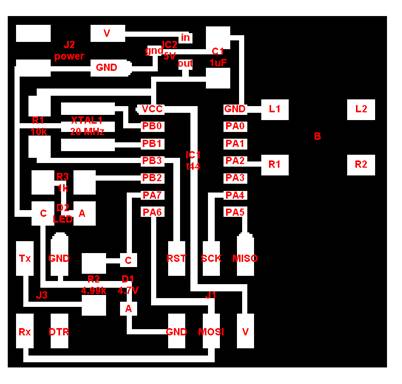

I was very excited to make another PCB since I enjoyed it so much the first time.† When deciding whether to add the button in cad.py or remaking the board in Eagle, I realized that the button was already described in the board and I would just have to add it in the correct place and add the traces.† While Iíll probably use Eagle in the future, cad.py seemed like a good quick method for the problem at hand.† I ended up having to download gedit though because both notepad and wordpad messed up the .cad files when I tried to edit them.† Good ole MicrosoftÖ

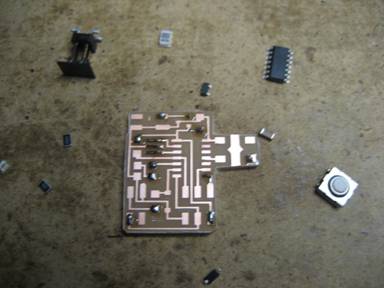

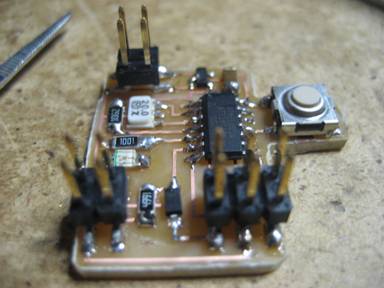

I then used the Modela this time (as opposed to Max and Ilanís home brew machine from last time).† The process was very streamlined and I was happy with how quickly I had my board.† I then gathered all of the necessary components and went to work on stuffing my second board ever!

I was very happy with both how quickly I was able to stuff the board and at how relatively nice the solder joints came out.† No re-work done here!

Programming

This was definitely the most difficult part of the assignment.† I started working with the .asm file and first went through the existing file to understand how it used the instruction set and registers from the data sheet.† After I felt like I had a handle on that I tried to implement my button as an interrupt.† I spent a long time trying to figure out how to set the correct bits to allow the interrupt and by the time I finally figured that out I realized that I had no idea how to catch the interrupt to have the chip do what I wanted!†

I searched through Google extensively, but apparently nobody writes in .asm!† While searching I decided that I was going to scrap the interrupt attempt and make the pin a standard input.† I ended up getting that to work, but because the program sits in the loop waiting to receive a character from the keyboard, the button press didnít show a result unless I held the button down and pressed a key.† While technically I completed the assignment because the button was doing something, I wasnít happy with it.† I was determined to get the interrupt method to work.

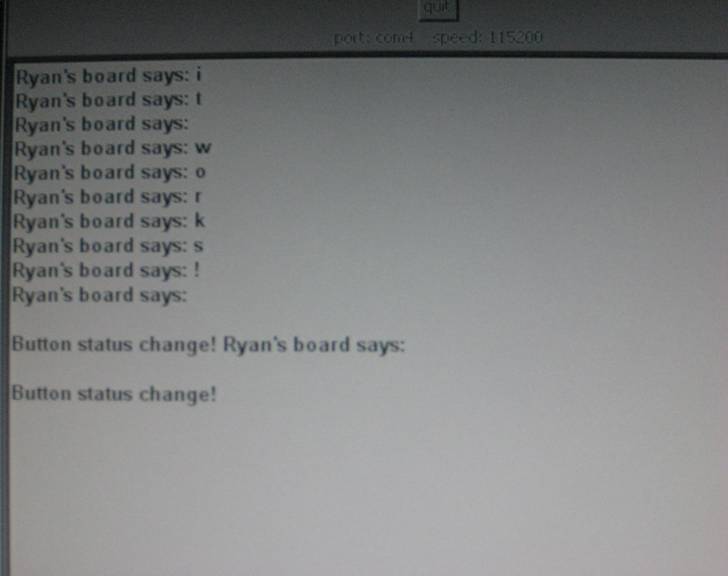

I did finally found a way to direct the interrupt I wanted (PCINT0) to do what I wanted it to do (blink the LED and print ďButton status change!Ē on the screen).† There isnít anywhere in the data sheet where I could have found it, so Iím glad I found it randomly online.† Anyway, once I got the .asm file to work I moved on to the .c file.† Everything went smoothly until once again I had trouble figuring out how to direct the PCINT0 interrupt to do what I wanted.† Luckily, AVR Libc makes this much easier.† I got it to work and was amazed at how much larger the .hex file was using .c (1530 bytes) instead of .asm (661 bytes).† I guess I can see why .asm is useful (grudgingly).

My code is here:

I used AVRStudio for my .asm programming and WINAvr for my .c programming.

And it works!!!

††