Final Project

I have cycled through a number of final project ideas from a lace lampshade (presented at the first day of class and pictured below), to a "smarter" stud finder, to an Acronym Blaster that would make a horrible sound any time an acronym was uttered.

But finally I decided to aim for simplicity and now plan to make a cork/plastic Frisbee that will light up in some interesting way when flying. The Frisbee part will be relatively normal-- cast from the mold I used in the molding and casting week. I need to find some clear two part plastic to use for the cork binder, though. The electronics will consist of a board with a 1 axis accelerometer and a line of charliplexed LEDs radiating out to the edge of the Frisbee.

But finally I decided to aim for simplicity and now plan to make a cork/plastic Frisbee that will light up in some interesting way when flying. The Frisbee part will be relatively normal-- cast from the mold I used in the molding and casting week. I need to find some clear two part plastic to use for the cork binder, though. The electronics will consist of a board with a 1 axis accelerometer and a line of charliplexed LEDs radiating out to the edge of the Frisbee.

Components:

Frisbee: - clear castable plastic

- hydrostone for outer shell of mold

Electronics: - Tiny44

- stock accelerometer

- LEDs (the stock ones might be bright enough, otherwise I will source some brighter ones. They need to be small, though. I only need about 10)

- various resistors and capacitors

Process:- make board with accelerometer and get working

- Make board with accel. and charliplexed LEDs and get working

- Practice embedding electronics in the cork/plastic casting

- Cast cork with embedded electronics

- Fly

Schedule:

I've already completed task #1 and begun task #2. I've also completed task #3 but need to try it again.

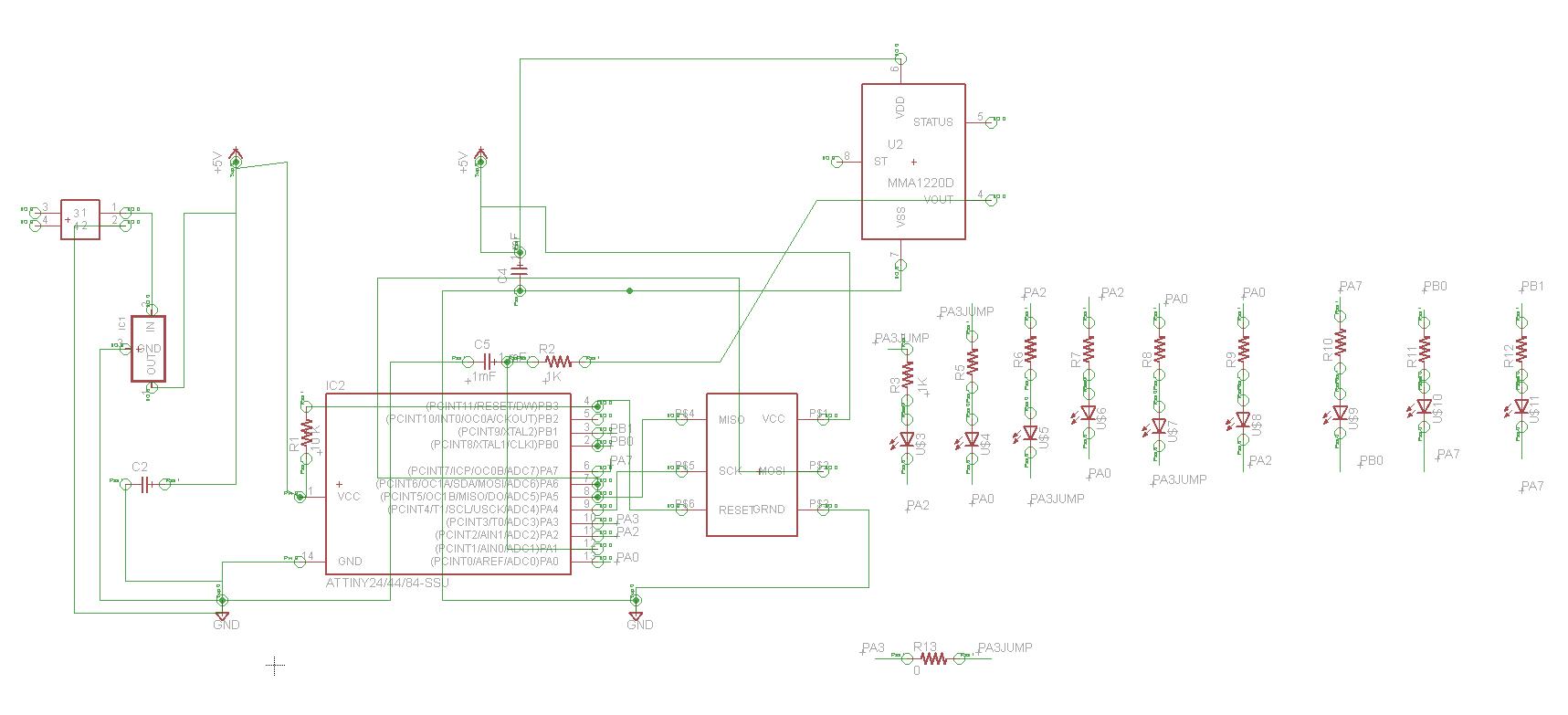

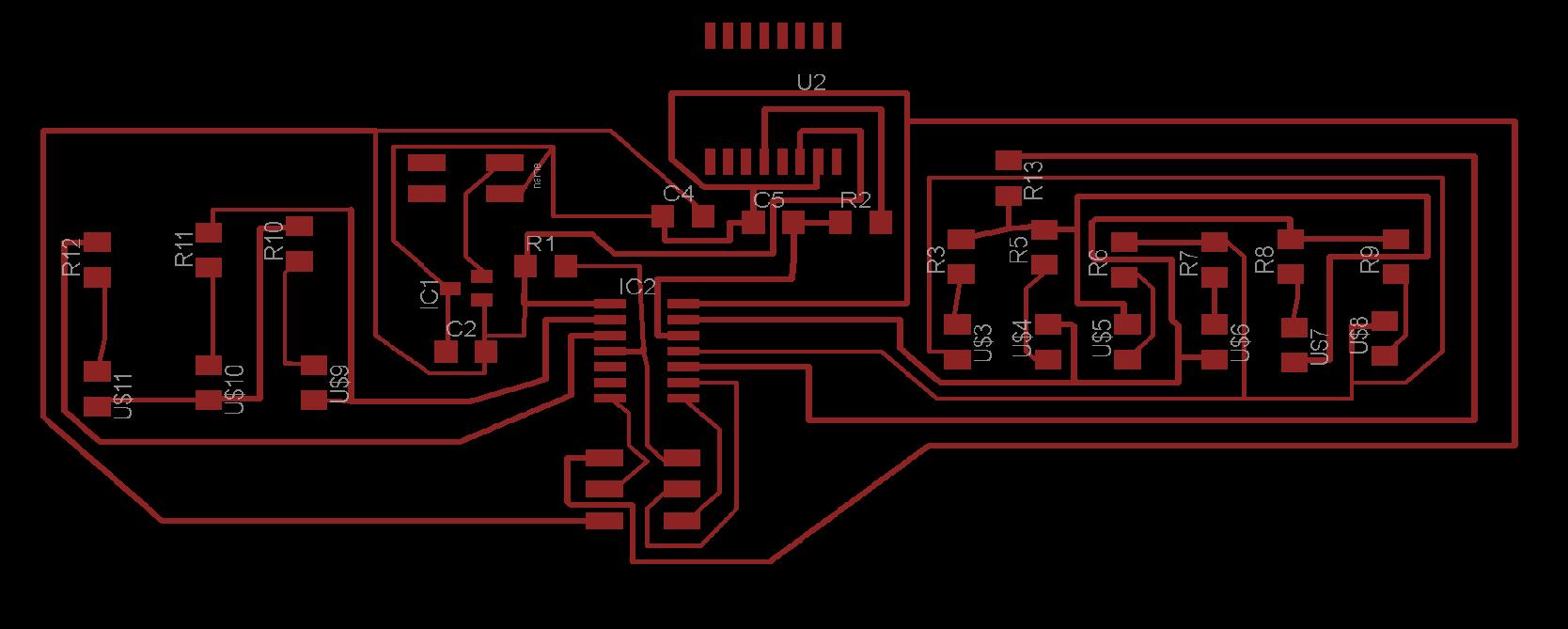

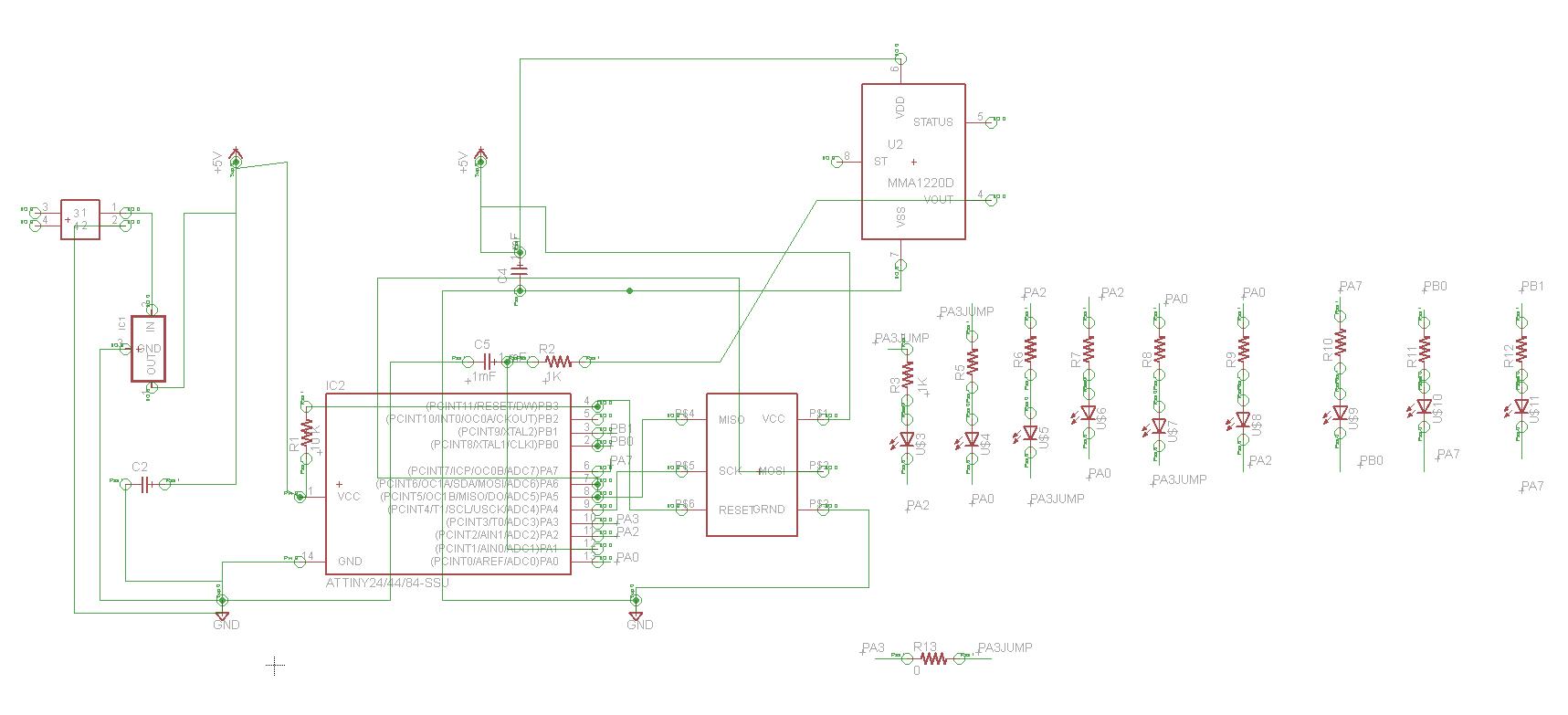

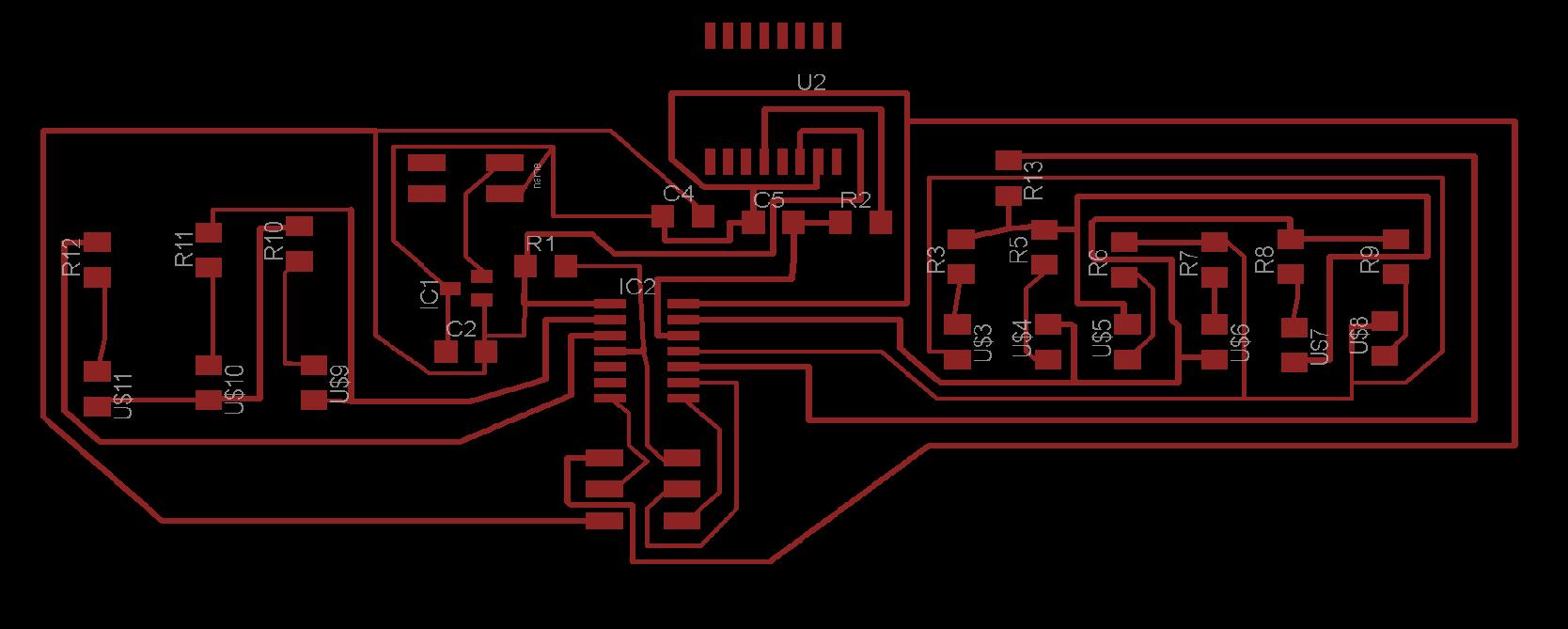

Here are the Eagle Schematic, Board and code so far:

Board

Schematic

Assembly Code

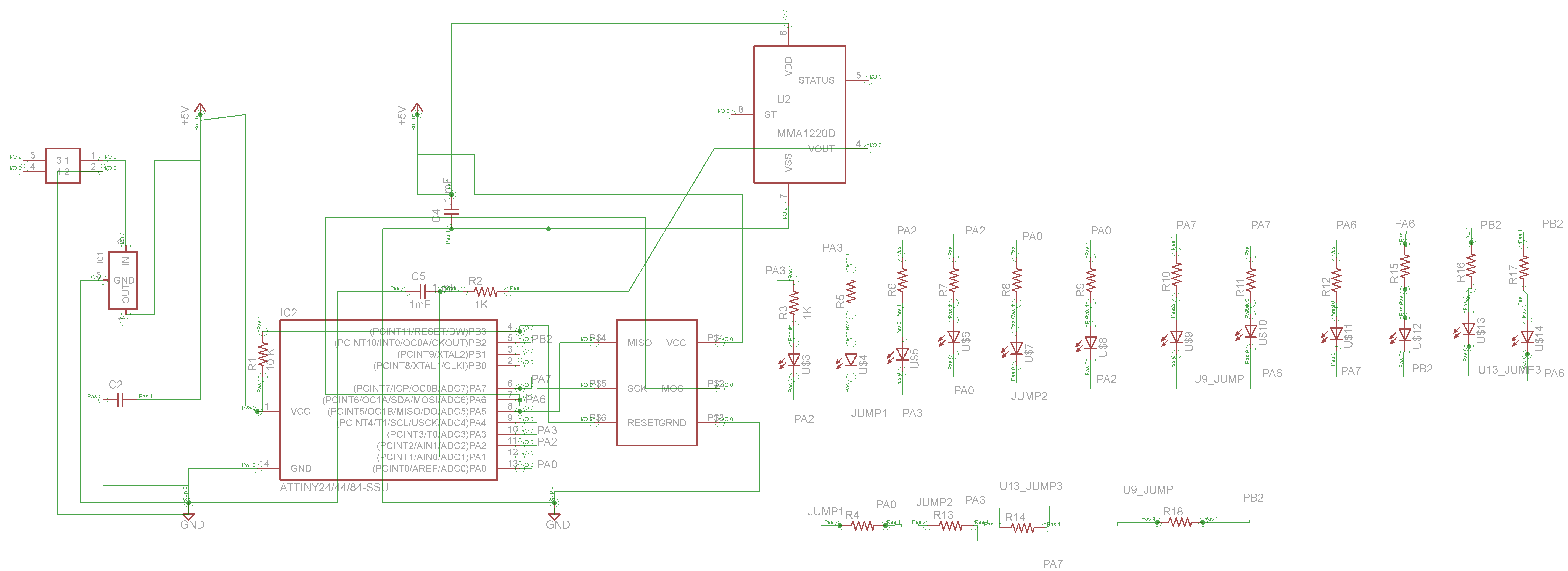

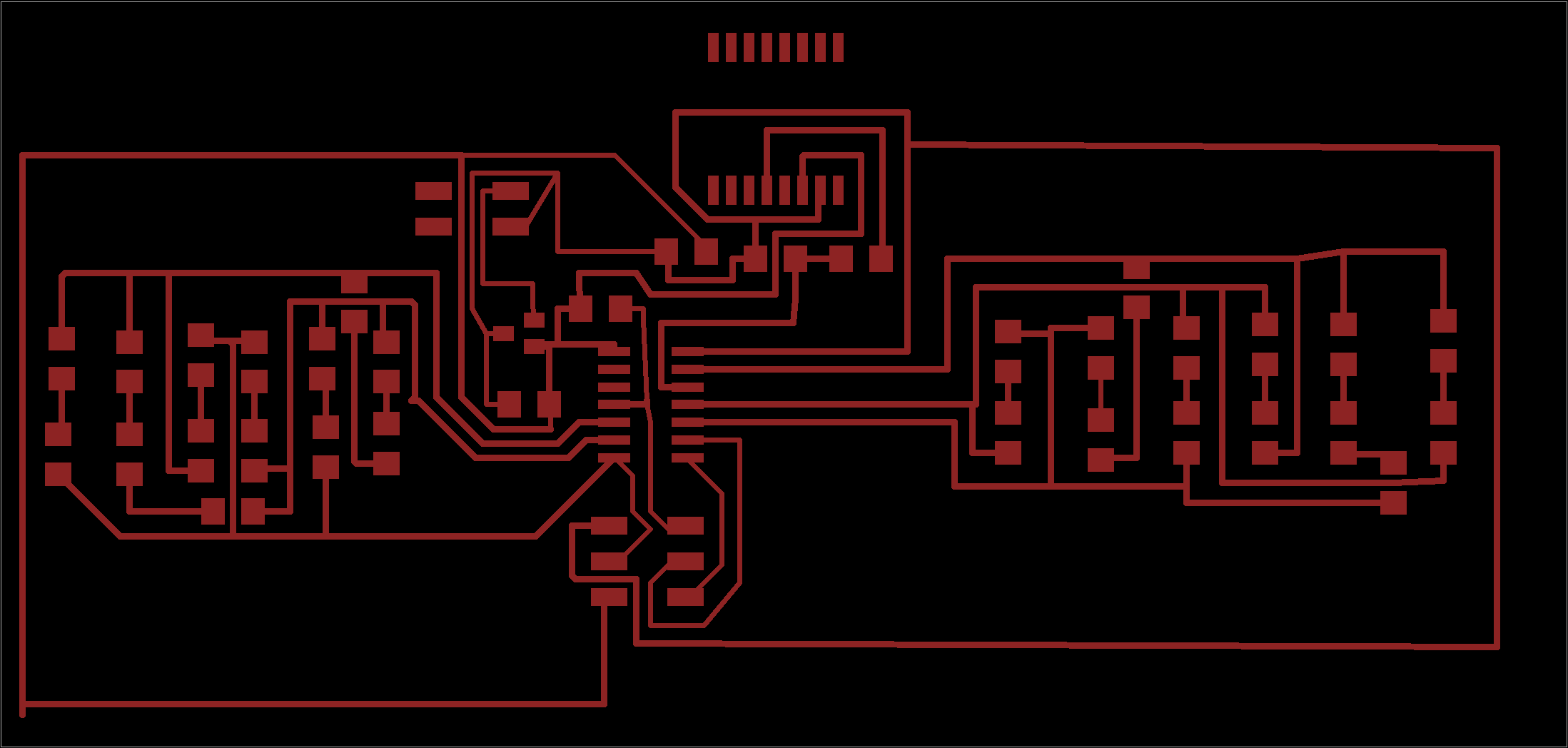

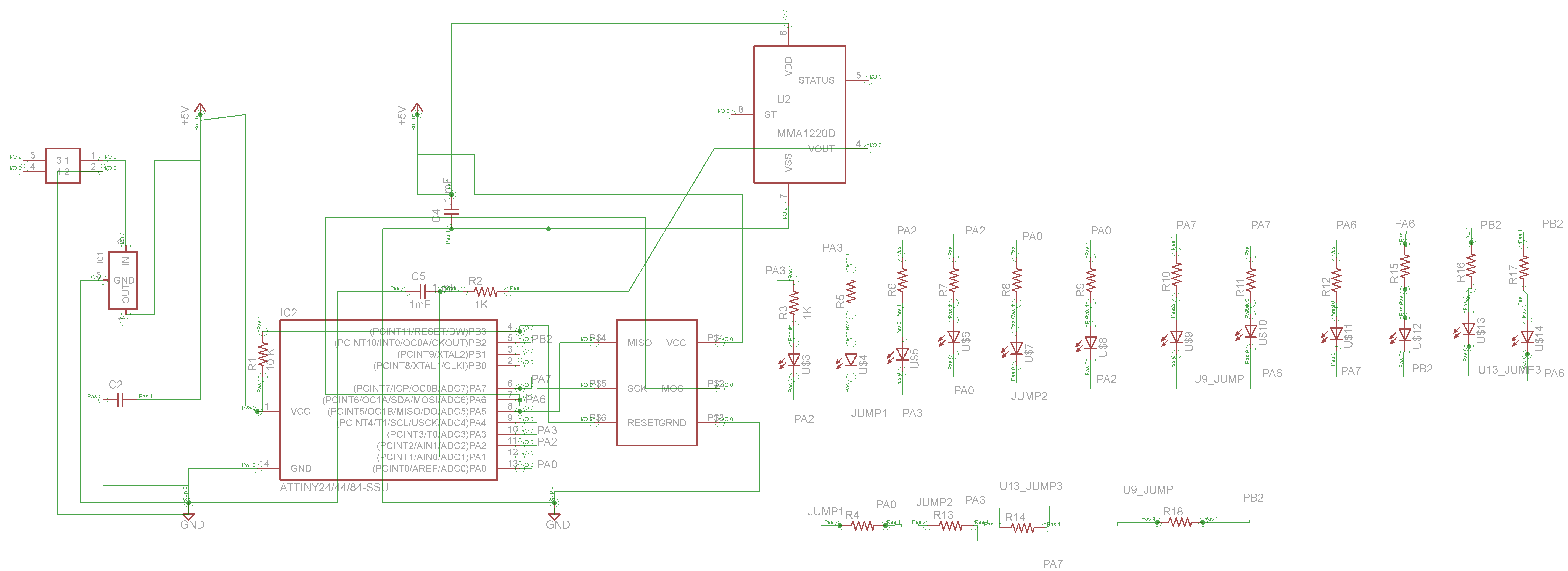

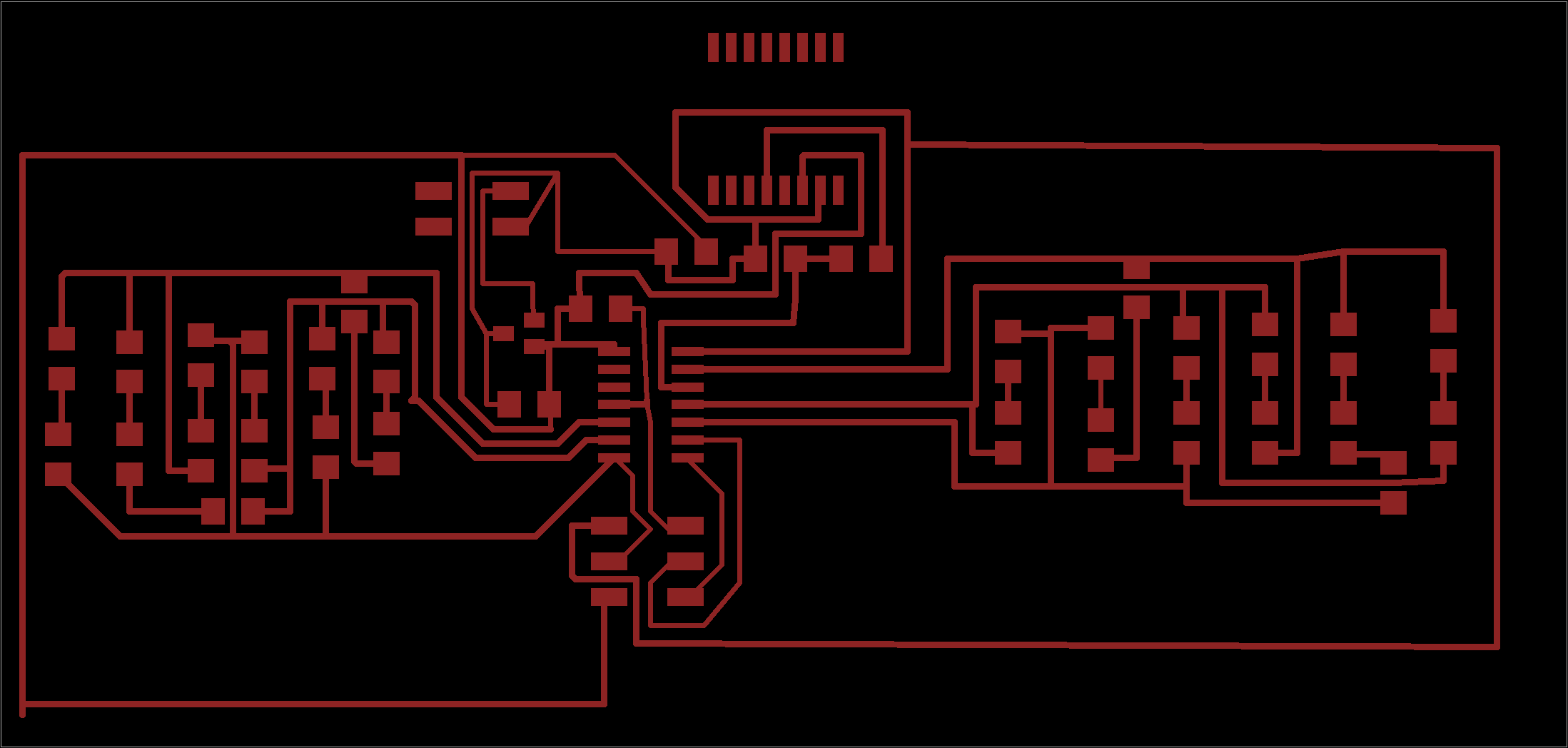

Here's the Eagle Schematic for the bigger Charliplexed board:

This week: - stuff and get working charliplexed board with accel,

- test embedding again,

- cast all by thursday or friday for debugging

This was an early post to this Final Project page:

The idea I presented in class that day was for a lace lampshade made from cork. The research project I'm working on for my thesis involves finding new uses for granulated cork which we mix with various binding adhesives. I'm interested in cutting a mold for the cork in a lace pattern, and then casting it in such a way that I can make a lampshade from it.

Another idea I've been toying with these days is for a "smarter" stud finder. A pet peeve of mine as cabinetmaker and installer was finding studs. The old guys I knew always employed the "tap on the wall" technique-- but it had taken them 20 years to learn it. What I'd like to make is a stud finder that will produce a map of the insides of the wall on a screen on the tool. Ideally it should be able to sense wood studs as well as wiring and plumbing. It should also need as few measurements by the user as possible. Below are some preliminary drawings.