:: ed baafi :: mas863 :: how to make almost anything :: Cutters

I never liked breadboards, but thought I'd play around with the concept this week

The theme this week was press fit building kits.. Breadboards are kind of like press fit for electroncs and they secure electroncs pretty well.. Besides the fact that breadboards are difficult for beginners (an audience I care about deeply) and that you have to use somewhat obsolete DIP components, one downside to breadbaords are the mess of wires that come with any decent sized project. I decided to address this by making stackable breadbaords which hide the connections between rows using two separate boards that would press fit together, sort of how traditional circuit boards have vias between layers. The idea is that you wouldn't design with these boards as they are even more confusing than traditional breadbaords but that you would design a schematic and a computer program would generate paper templates of the component and via positions that you would overlay and use as a guide.. This would facilitate more robust semi-finished projects than with a breadboard and a much easier build than a traditional circuit.

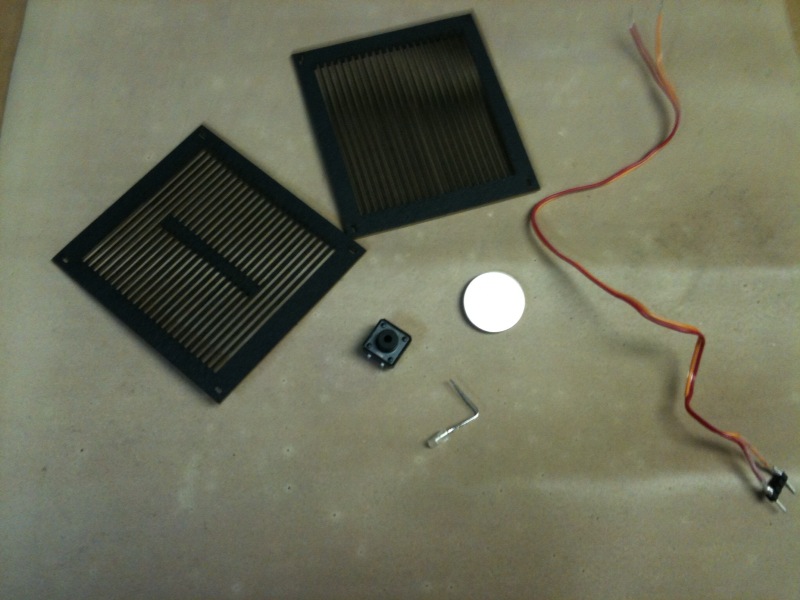

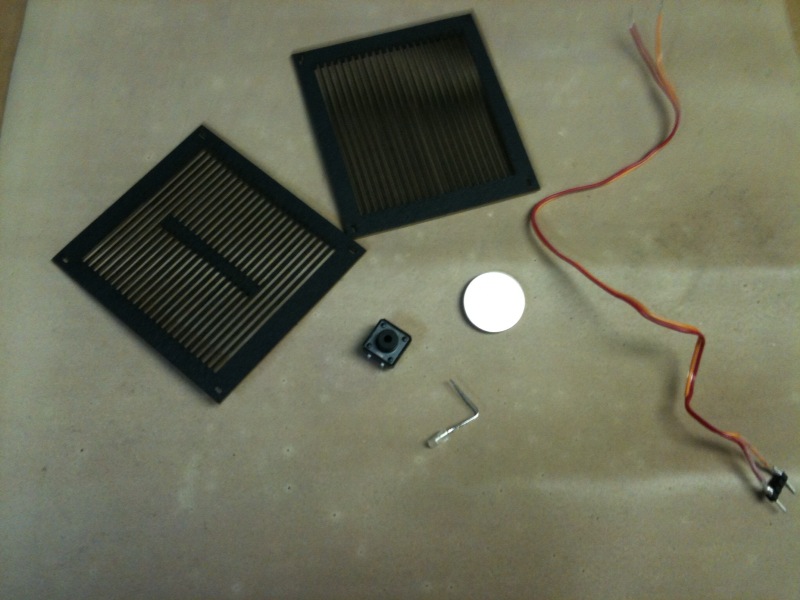

Here are my laser cut matrices with some components and the "conductive rubber" I used as component inserts

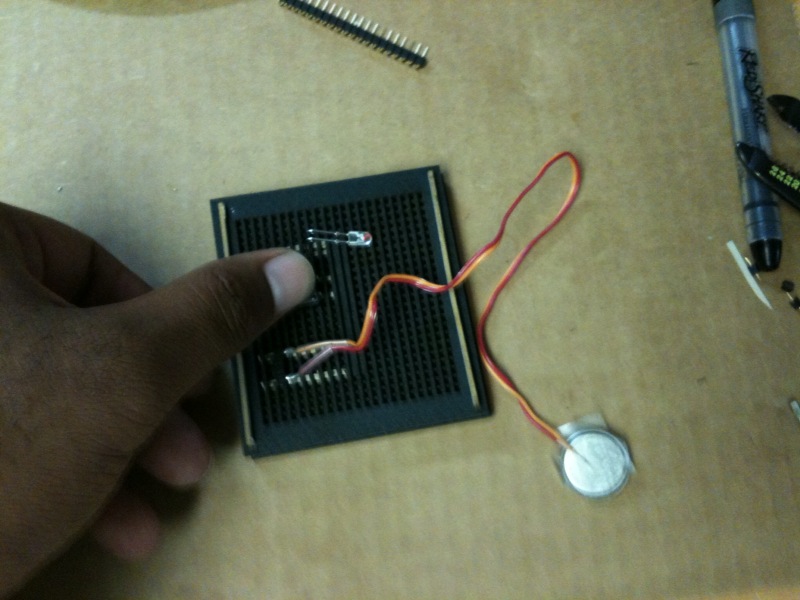

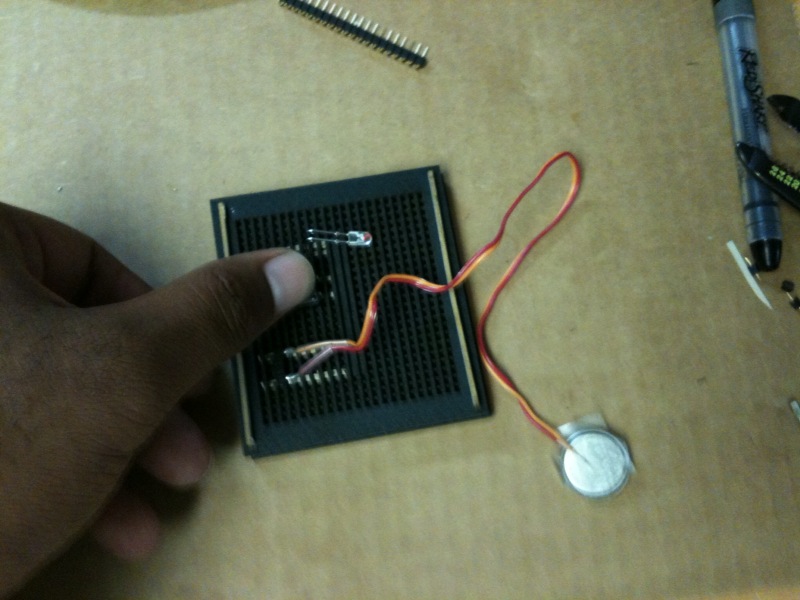

Here is the bottom board wth vias inserted

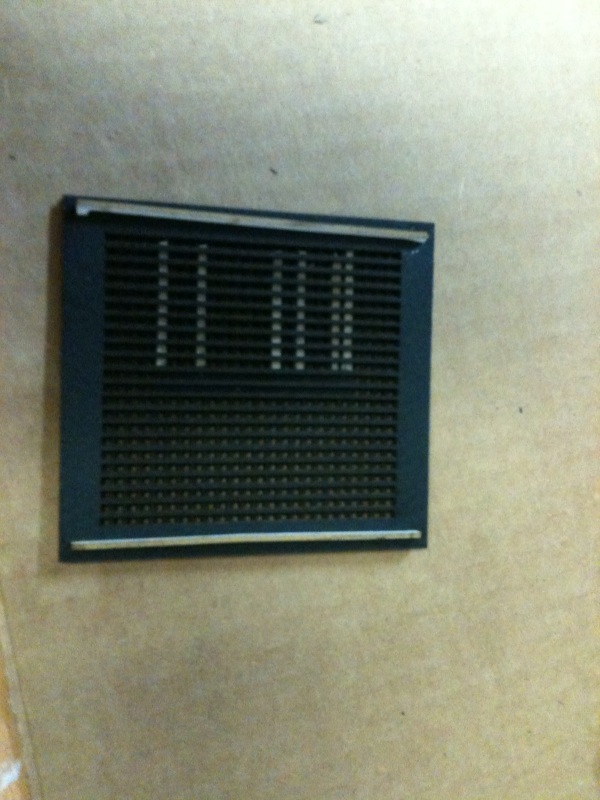

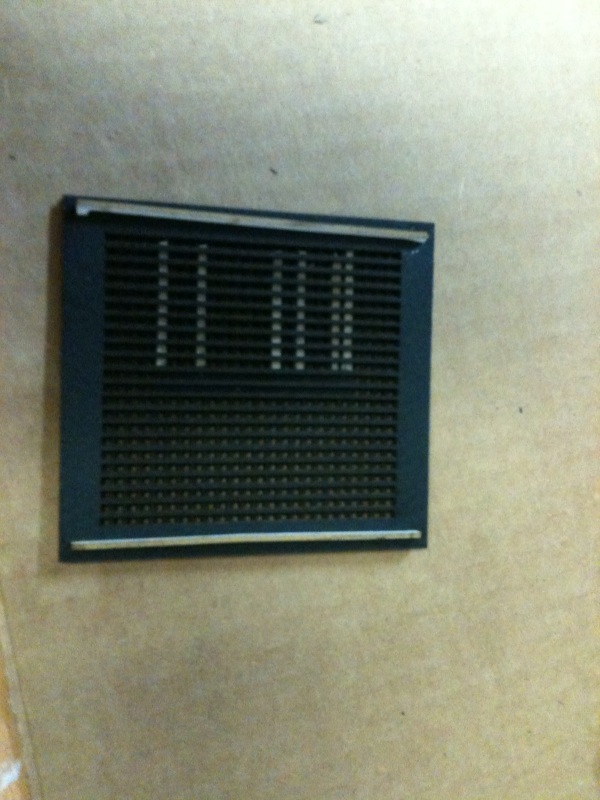

Here is the top board

Here I am pressing the button and turning on the LED.. There are a bunch of issues with the current design including the fact that I didn't want to laser cut the mystery conductive rubber so I may revisit this in later weeks such as molding and casting where I can cast the rubber