|

|||

|---|---|---|---|

| MAS.863.10 | Masoud Akbarzadeh | MArch | SMArchs | Computation | |

| How to Make almost everything | MIT department of Architecture | ||

| Home | | |||

|

|||

| molding and casting | | |||

THe exercise for this wee was to make a mold and cast into that. I decided to make a mold for part of my final project proposal.

|

|||

|

|||

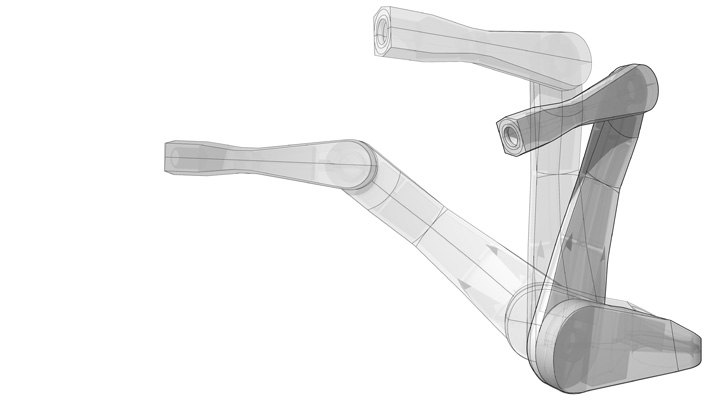

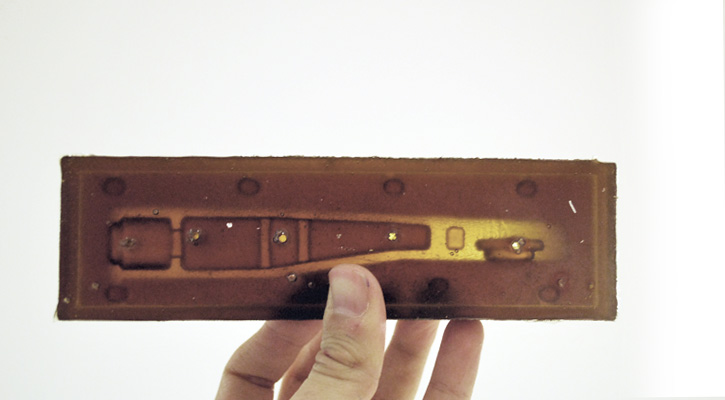

This is the model for the 4 Axis robotic arm which I would like to finish by the end of the semester. For this week I made the model and took the last portion of the arm for manufacturing experience.

|

|||

|

|||

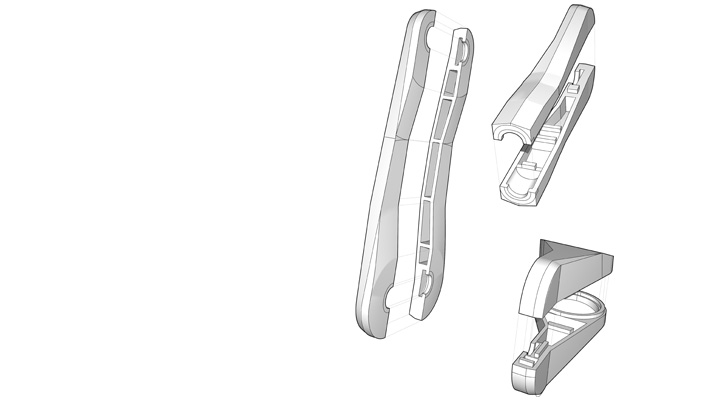

In order to make the assembly of the whole arm feasable, I divided each member into two segments; a male and a female. The male has some tabs which interlocks with the female for assembly process.

|

|||

|

|||

| Each member is divided into two segments and each segment would be divided into exterior and interior. | |||

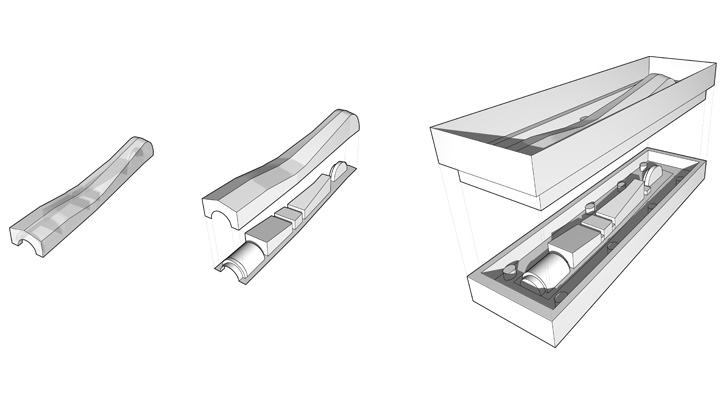

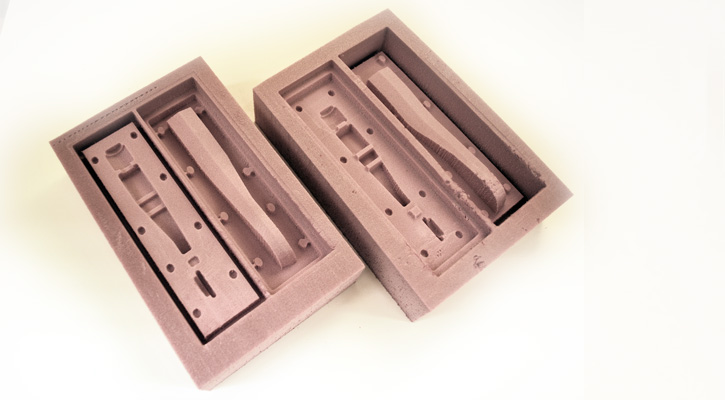

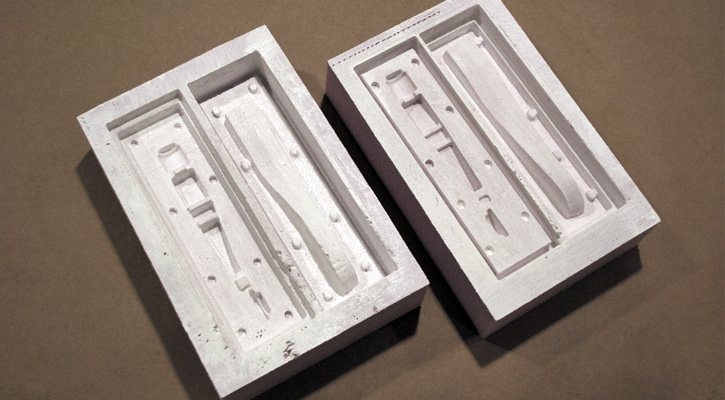

Making the mold for a halow mamber is a little bit tricky. in order to design the mold, it is important to seperate the whole exterior surface of the model from the interior. Later there should be a mold for exterior and the one for interior.

|

|||

|

|

||

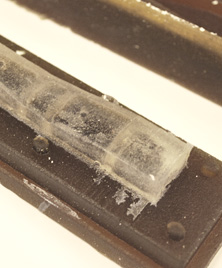

The whole surface looked very clean except some parts which were hit by the plastic sheild of the vacume around the mill. Later I had to take off the plastic sheild for cleaner cuts.

|

Later I used CNC machine to make the mold for the molds. I used 1/4" end mill (ball end) for Horizontal roughing with 50% step over, and 1/8" end mill (Ball) for the Horizontal Finishing with 10% step over.

|

||

|

|

||

Using a large amount of material might fill the some small parts of the mold and change the accuracy of the mold.

|

Before pouring the polyurethane into the molds, the surface of the mold should be covered with a thin layer of Geso. You should be very patiant to use very little material for covering.

|

||

|

|||

The next step is mixing the polyurethane in a separate dish.

|

|||

|

|

||

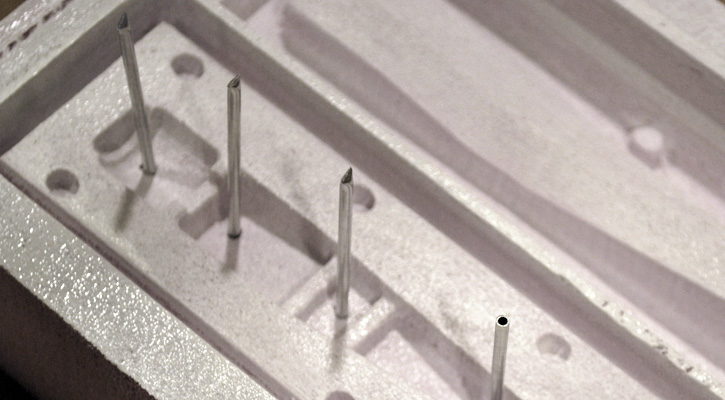

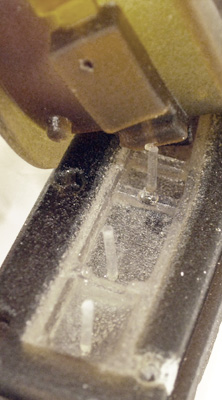

| 1/8" diameter Aluminum bars. | In order to think ahead about the casting part, I need to use some ventilation pipes in the mold itself. I use Aluminum rods for this objective.

|

||

|

|

||

| Th rods are coming out of the liquid. | The molds after pouring polyurethane.

|

||

|

|||

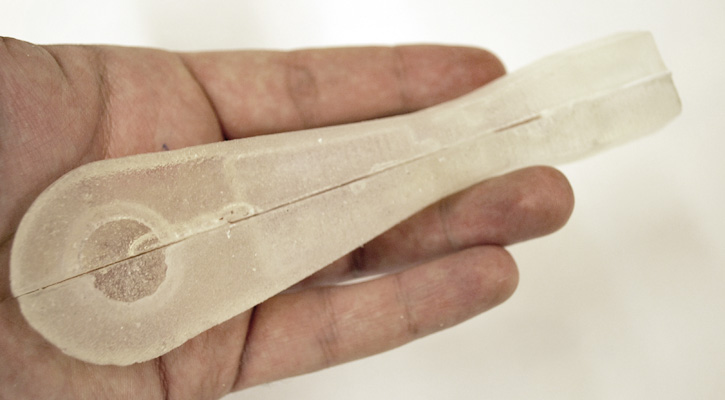

16 hours later the polyurethane cured and flexible

|

|||

|

|||

|

|||

The process of detaching from the foam and Al. rods

|

|||

|

|||

Two molds for one part on top of eachother

|

|||

|

|

||

| It is better to put two layer of stiff materials around the molds not let the rubber bands to cut the flexible mold | Now, it is time to cast the Smooth Cast Plastic into the molds. I used syringe to inject the cast into the molds.

|

||

|

|

||

|

|

||

Final Step opening the mold and detaching the part from the mold. there are some problems regarding this part. the Male part didn't have a very good tabs to go inside the female. I guess this needs more experience in how to desig the tabs in a more efficient way. (further investigation of course!!)

|

|||

| All Rights Reserved 2010 | |||