For this week's assignement, we were supposed to 3d mill a mold and cast something in it to get a 3D object.

I chose to work on 3 projects : a soft tentacle form as a trial for my final project, some soft magnets and chocolate.

Tentacle

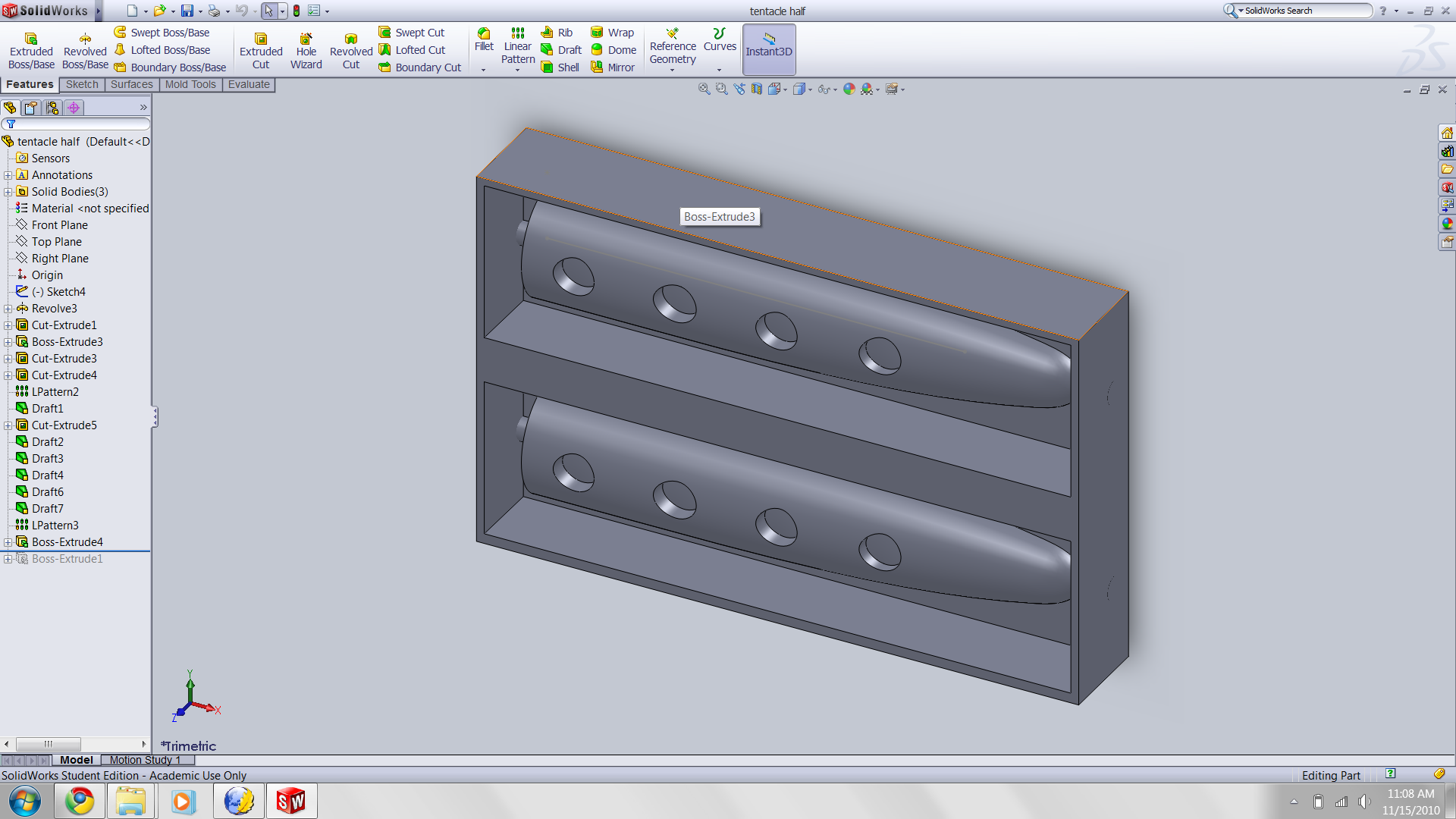

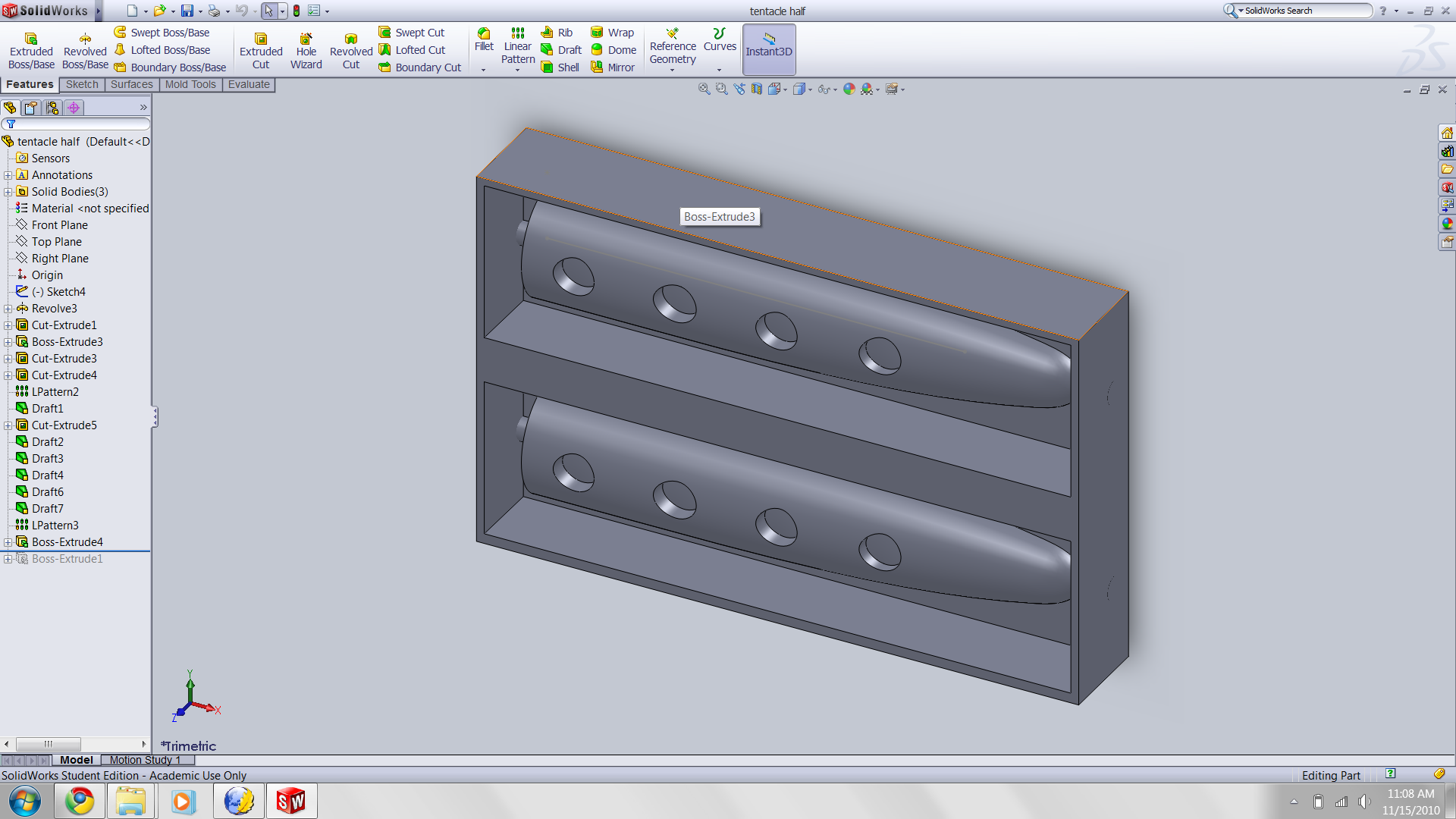

For the tentacle, i machined 2 parts for the mold on the shopbot in the machining wax. I used 12000 rpm, 1.7 plunge rate & feed and a 1/8" ball nose end mill since my object had alot of curvature. The process took about 1h30. A thing to note is that when you hotglue the wax on the wood, you want to make sure that there is enough glue to hold the wa because halfway through my job the wax went flying and i had to start over. The tentacle has some holes in case i want to embed things in it (such as magnets). The two protrusions at either end are for the entry hole and air hole. The advantage of molding vs other techniques we learned for this is that i can embed wires and magnets in it in the making process. The CAD was made using Solidworks and i used a draft of 3 degrees.

I then casted the dry polyurethane rubber into the mold and left it overnight to set.

The soft mold came out without alot of trouble.

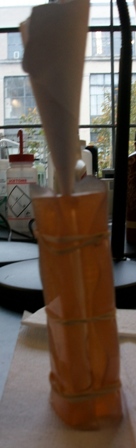

For the object itself, i opted to use soft silicone (usually used for dental care). The advantage of this is that the material is very soft at the end. I tried a couple of them which have different stiffnesses to test them. They have a working time of about 5 min and a setting time of about 20-30 min.

I closed the mold and let it sit for about 40 min then removed and here is the final result. In retrospect, I should have left more air holes for the silicone to dry because when it came out, it was solid but gooey on the surface which solidified later.

Soft Magnets

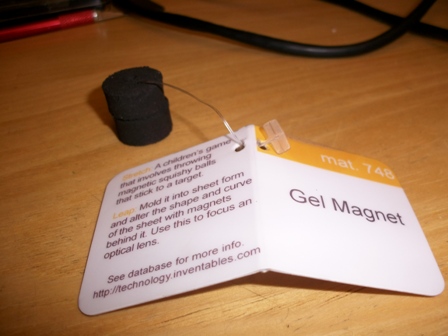

I found these soft magnets online and the process seemed simple enough so I decided to try to make my own. This was also nice because it would let me expermient with addititives with the casting.

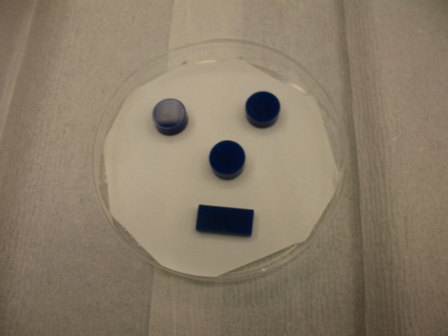

I used the lasercutter to make shapes and then made a mold using the back of the vinylpaper and a petridish. I used the dry polyurethanr rubber to make the soft mold.

This time i had trouble removing the mold out of the petridish (no draft?), i had to break it.

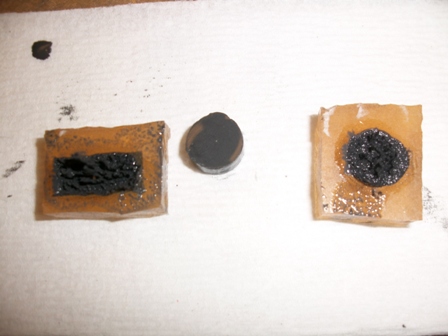

I then mixed some iron carbonyl particles in the soft pink silicone and made 2 batches : one which dried outside and one which was drying in an electromagnet with a strong magnetic field. The one in the magnet should become a permanent magnet if this works properly. Something to keep in mind is that the magnet i used was very powerful and i almost burnt the molds from the heat.

Again, things seem to have solidified except for the outer surface which stayed gooey (20 min in the magnet).

The pieces cant be attracted using a magnet but they are not permanent magnets!!! Maybe i need to increase the particle concentration or seal the top so sll the particles dont migrate like in the pictures.

Chocolate

i wanted to mold chocolate in the form of the GradRat this week. I tried using the vacuum forming machine & PETG plastic to do it but I couldn't get it work because of the shape of the ring and its small size. i decided this was a lower priority project that i will pursue later.

I chose to work on 3 projects : a soft tentacle form as a trial for my final project, some soft magnets and chocolate.

Tentacle

For the tentacle, i machined 2 parts for the mold on the shopbot in the machining wax. I used 12000 rpm, 1.7 plunge rate & feed and a 1/8" ball nose end mill since my object had alot of curvature. The process took about 1h30. A thing to note is that when you hotglue the wax on the wood, you want to make sure that there is enough glue to hold the wa because halfway through my job the wax went flying and i had to start over. The tentacle has some holes in case i want to embed things in it (such as magnets). The two protrusions at either end are for the entry hole and air hole. The advantage of molding vs other techniques we learned for this is that i can embed wires and magnets in it in the making process. The CAD was made using Solidworks and i used a draft of 3 degrees.

I then casted the dry polyurethane rubber into the mold and left it overnight to set.

The soft mold came out without alot of trouble.

For the object itself, i opted to use soft silicone (usually used for dental care). The advantage of this is that the material is very soft at the end. I tried a couple of them which have different stiffnesses to test them. They have a working time of about 5 min and a setting time of about 20-30 min.

I closed the mold and let it sit for about 40 min then removed and here is the final result. In retrospect, I should have left more air holes for the silicone to dry because when it came out, it was solid but gooey on the surface which solidified later.

Soft Magnets

I found these soft magnets online and the process seemed simple enough so I decided to try to make my own. This was also nice because it would let me expermient with addititives with the casting.

I used the lasercutter to make shapes and then made a mold using the back of the vinylpaper and a petridish. I used the dry polyurethanr rubber to make the soft mold.

This time i had trouble removing the mold out of the petridish (no draft?), i had to break it.

I then mixed some iron carbonyl particles in the soft pink silicone and made 2 batches : one which dried outside and one which was drying in an electromagnet with a strong magnetic field. The one in the magnet should become a permanent magnet if this works properly. Something to keep in mind is that the magnet i used was very powerful and i almost burnt the molds from the heat.

Again, things seem to have solidified except for the outer surface which stayed gooey (20 min in the magnet).

The pieces cant be attracted using a magnet but they are not permanent magnets!!! Maybe i need to increase the particle concentration or seal the top so sll the particles dont migrate like in the pictures.

Chocolate

i wanted to mold chocolate in the form of the GradRat this week. I tried using the vacuum forming machine & PETG plastic to do it but I couldn't get it work because of the shape of the ring and its small size. i decided this was a lower priority project that i will pursue later.