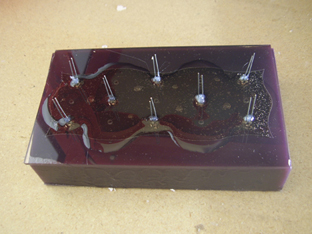

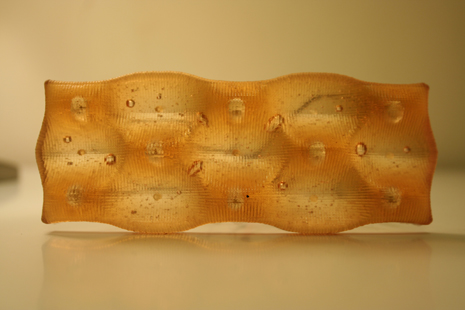

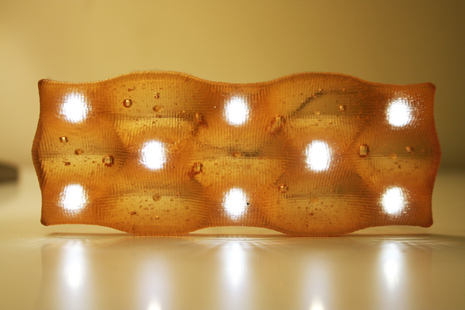

At first I tried the PMC 121-30 wet, plastic semitransparent rubber with a golden color. I hot glued 8 white LEDS to the cap, mixed the PMC and poured it. Its curing time is 16 hours or 1 hour in the oven, but at first I was afraid that the acrylic part could melt or warp in the oven so I tried using a light to help it cure faster, but after waiting for 2 hours it did not seem to help that much so I put it in the oven. One hour at 175 F (80 C) and the cast was done. The first try went very well so I decided to try other combinations of colors and lights.

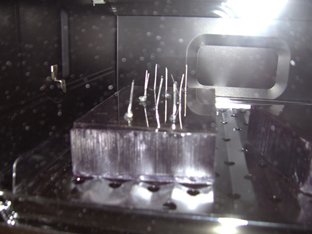

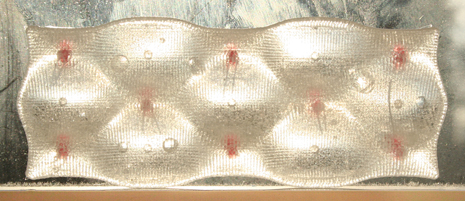

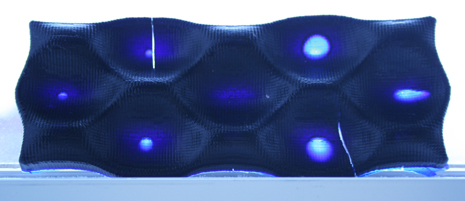

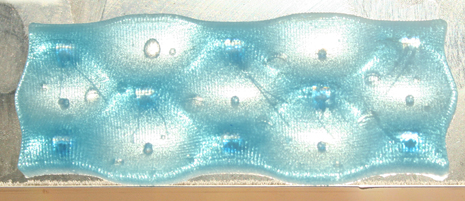

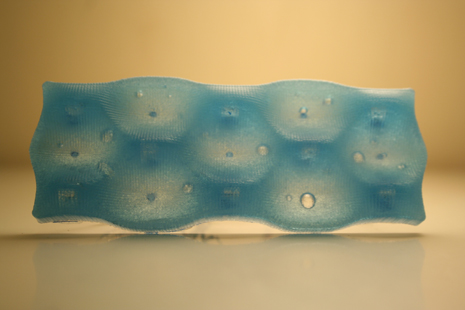

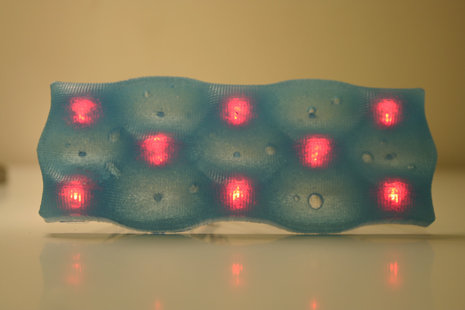

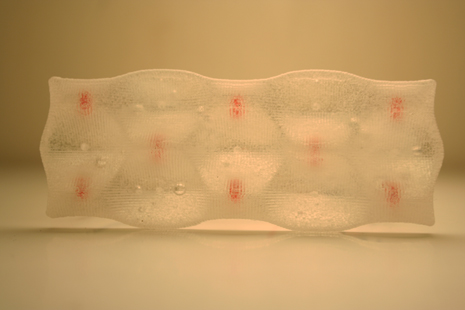

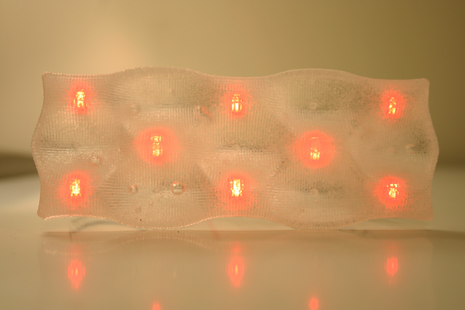

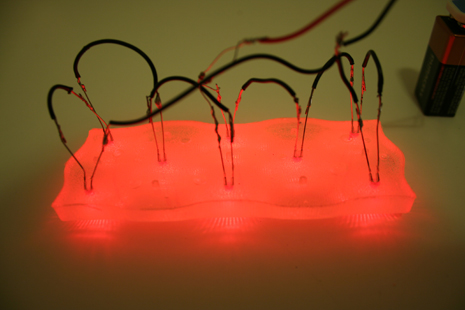

After that I tried the (transparent) liquid plastic (Smooth-on 325) that cures in about 10 minutes and is very hard after cooling. I mixed it with red LEDs. That also went very well. So I decided to do one more with the same 325, but mixing it with blue pigment. I used approximately 3 drops which proved to be a big mistake because the resulting color was so dark that the LED's light was barely visible. I took out the LED and tried one more time, this time using much more less than one drop and it kind of worked, giving a kind of light blue semitransparent color. |