Final Project Proposal

I plan to make a MPSLA (masked projection stereolithography) machine by the end of the semester. I will use the tools and knowledge that I learn in MAS.863 to make something that creates 3D parts based on a CAD file input.

What is an MPSLA? It is a form of digital fabrication in which layers of photopolymer resin are selectively exposed to light through some kind of dynamic pattern generator. A complex 3D shape can be built up as the successive layers of exposed polymer harden. MPSLA is a kind of stereolithography (SLA). In traditional SLA, a UV wavelength laser is directed by a pivoting mirror over each voxel on the resin layer that needs to be hardened. MPSLA has several advantages over traditional SLA:

- Only one moving axis

- An entire layer can be exposed at once

- Finer resolutions can be achieved by focusing a large pattern array onto a small area

I have been experimenting with various aspects of this concept to determine its feasibility. One of the disadvantages of SLA is that the photopolymer resin is often expensive. In order to keep costs down, I will initially be using UV cure solder mask (samples of which can be had fairly easily) as a substitute for the photopolymer resin.

Planning:

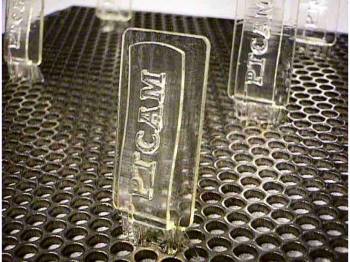

I plan to use an LCD screen to generate a selectively transparent mask as a filter for the UV light. To get an idea of the resolution achievable with this method, I took the LC panel out of a full size LCD monitor and placed it on top of an overhead projector. I then coated a piece of plastic with a thin layer of screen printing photo emulsion to model a layer of photopolymer on a substrate. I displayed a bitmap image on the LCD, turned on the projector bulb, and let the substrate sit on top to cure. The result was a 0.2mm thick solid layer of the pattern.

MPSLA machine subsytems:

- Dynamic pattern generator

- Z-stage

- Mechanism for ensuring uniform layers

- 3D model slicer and bitmap generator

- Control system for Z-stage and for outputting bitmaps

- UV light source, including collimator and focusing reflector

Ideally, I would like to control the display directly with a microcontroller, so that I do not have to rely on a proprietary system. The Z-stage and control will have to be quite fine (about .1 mm). During reciation last week, we were shown a plugin for Rhino that would slice a 3D model. I imagine something like this for my machine. I currently have a black light bulb that I have been using to generate UV light, and while it is not as powerful as I would like, it may work. I have a fresnel lens collimator. One option for ensuring uniform layers is to dunk the substrate under the resin bath and raise it again and wait for the excess resin to run off. This may work well with actually photopolymer, but soldermask is quite viscous and I may have to come up with another solution. The build volume will only need to be small at first (3" x 3") to save money. I have modeled in Solidworks an idea of how I want the project to turn out:

In reality, all of these ideas may change as I learn more about the processes available to me and act on advice and suggestions from others.

Pictures of existing SLA: