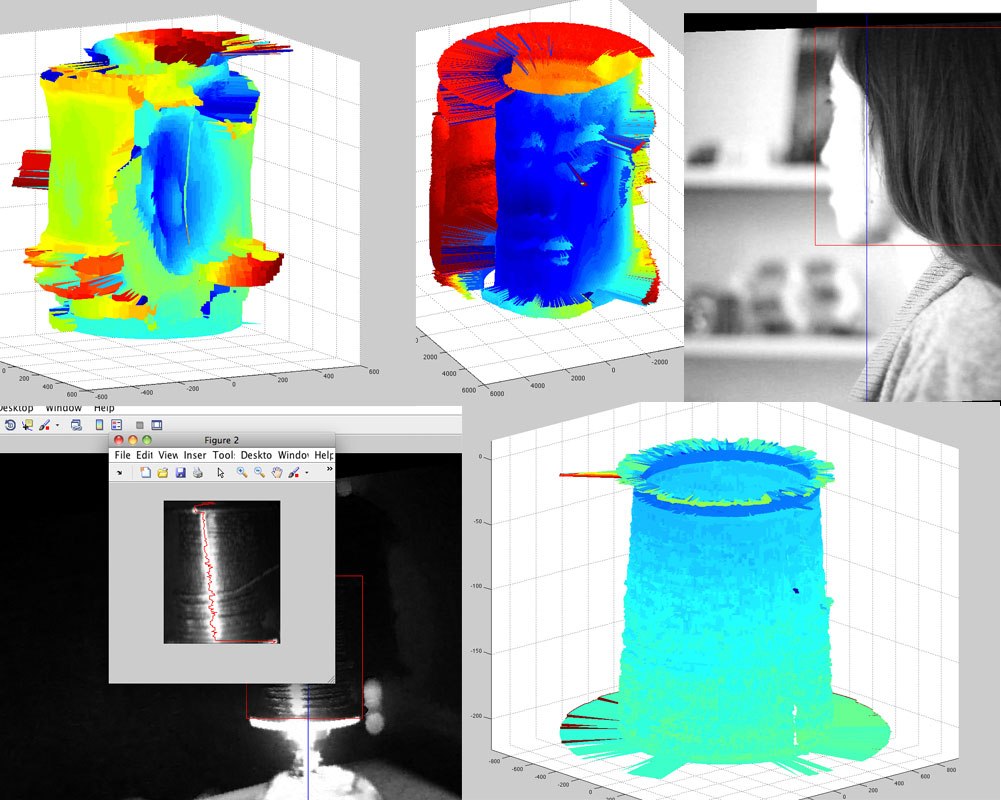

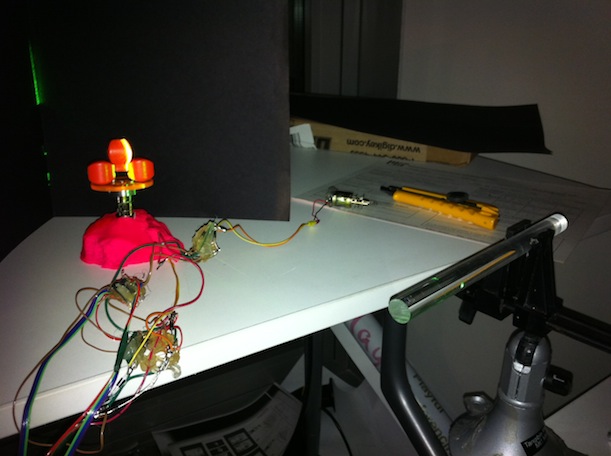

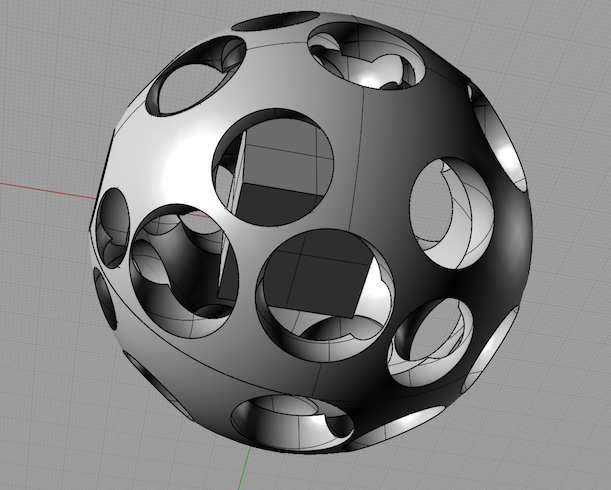

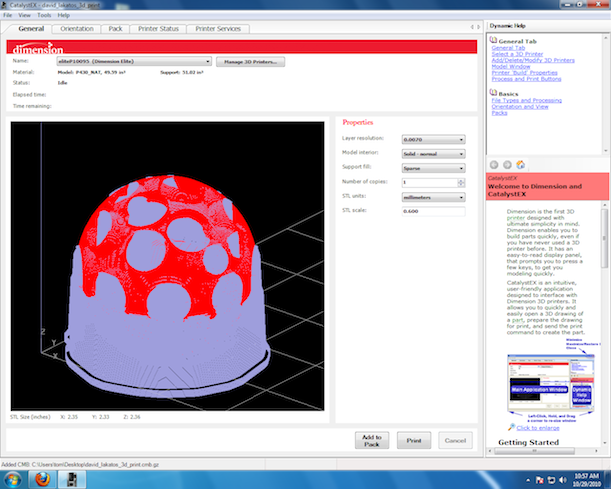

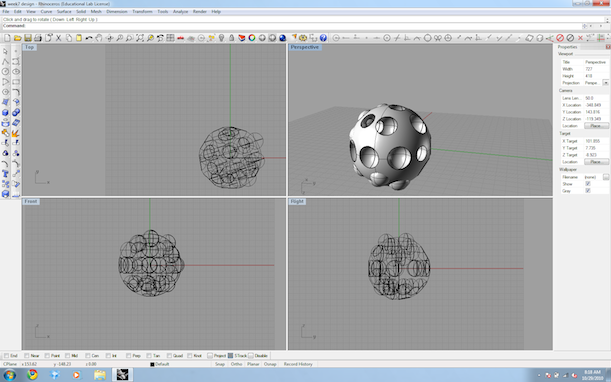

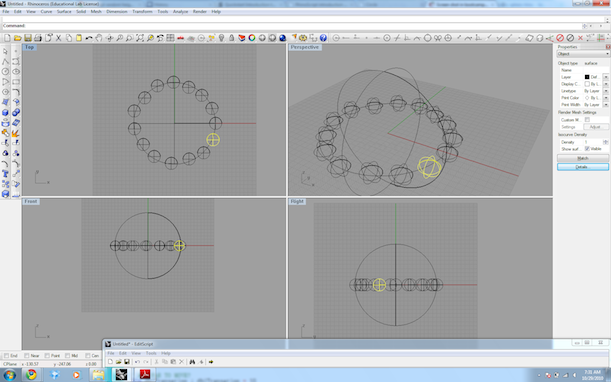

Throughout this week I dwelled into some techniques in 3D scanning and printing. In scanning I scanned with two methods: laser scanning and structured light. For printing I designed my own object.

The three methods I experimented this week are fundamentally different from each other, in terms of technology, cost and fabbability. Laser scanning and structured light are both fairly easy to set up, where as the Z camera is an expensive but very reliable alternative. All of the methods I used are 2.5D scanners - they only scan the surface of a material. In order to scan the whole object one has to build a rotating stage which is an I/O stage, where the position can be read and actuated at the same time.

.m file Cyrt Kenneth Jensen