Matt Blackshaw

Week 2: Vinyl Cutter and Laser Cutter

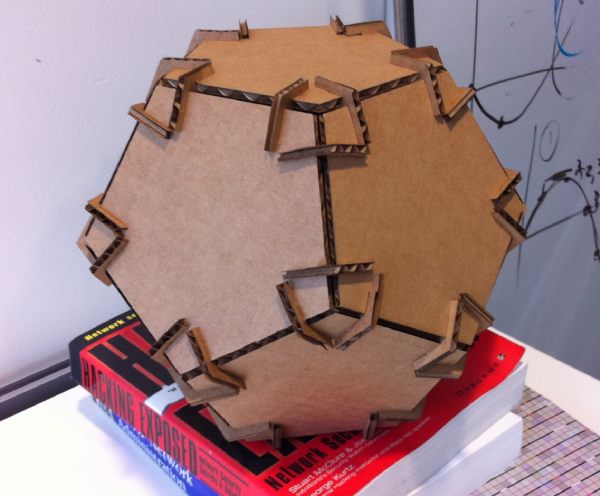

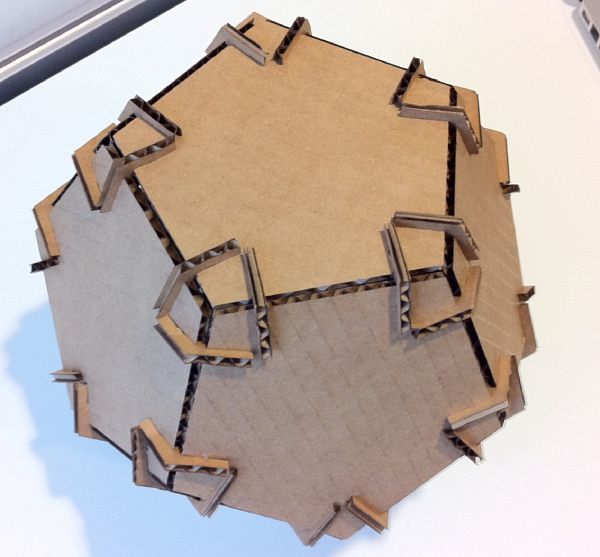

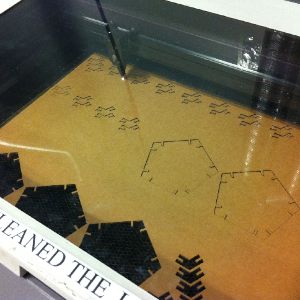

Pressure fit dodecahedron

Learning and Playing

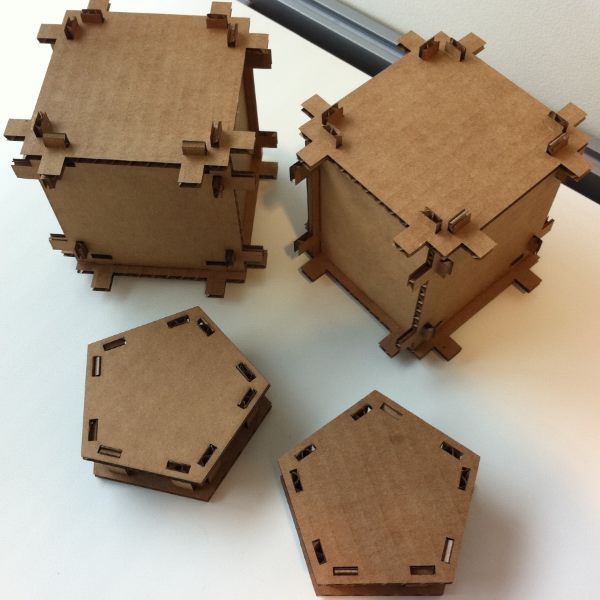

After cutting of some test pieces and assembling a couple of test cubes I found that the width for a sturdy press fit (using ECT 44 cardboard) joint is 0.152in. I also found that ECT 44 is surprisingly strong and the braces of a press fit joint need only be a width of 0.2in.

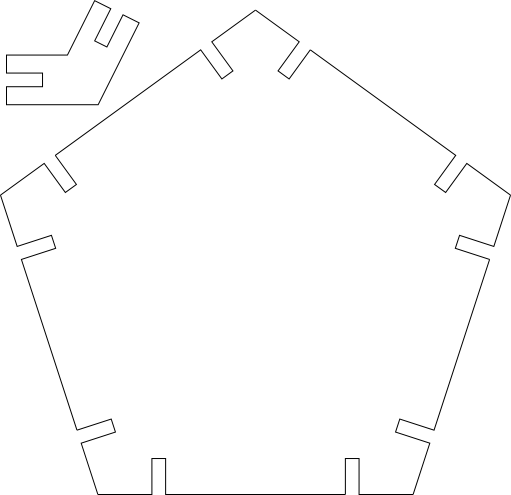

Design and Cutting

After working out all the angles (the dihedral angle of a dodecahedron is 116.565°), I drew my design and pieces using Inkscape and saved the output as SVG (Plain SVG was the only format that opened reliably with Corel Draw in the Fab Lab).

Assembly and Final Product

Putting together the first half of the dodecahedron was simple, but due to the convex angles at the corners and edges things got a little tricky. Fortunately cardboard is a malleable substance and I was able to shuffle all the pieces into place. Were I to assemble the same kit out of acrylic, I would need to revisit my joint design to ease assembly.