Matt Blackshaw

Week 9: Molding and Casting

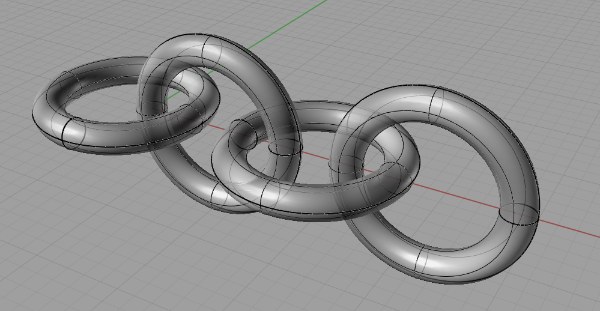

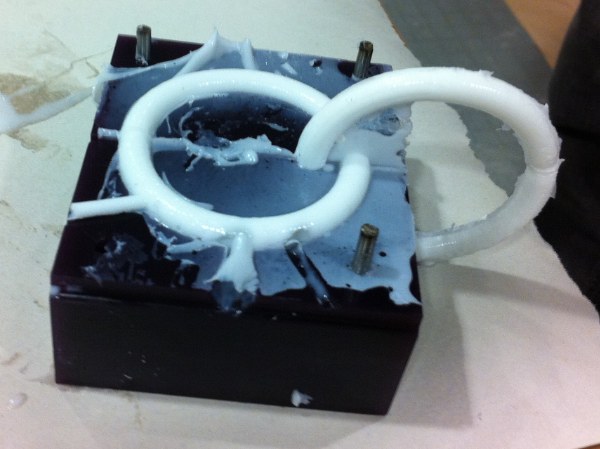

Linked rings

The idea

A mold for casting of linked rings.

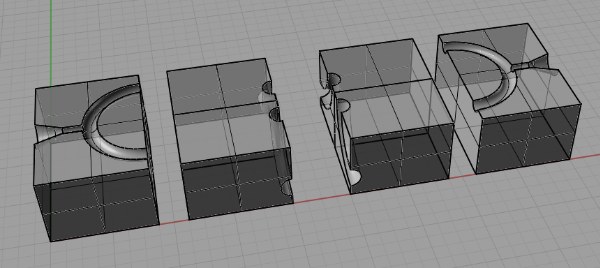

Mold model design

Creating connected rings requires a 4 part mold, which requires milling each wax block from two different sides on a 3-axis machine. Both the exploded and complete blocks are shown below. The model was created using Rhino.

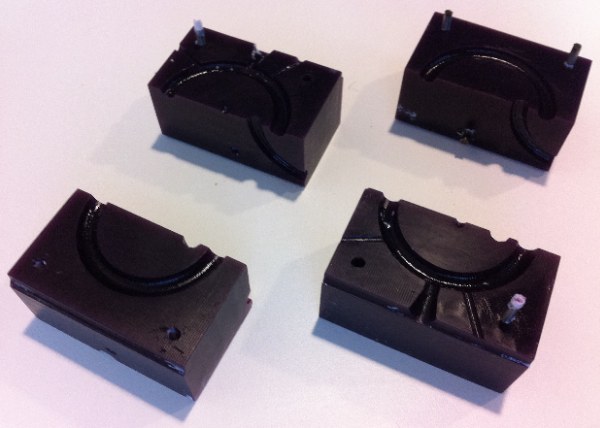

(8 hours of) Milling

Before milling I had to prepare 4 blocks of wax of the same dimensions. This was simple using the Bridgeport hand miller. I then milled each of the blocks on the Modela. To ensure they were properly aligned I used the grid markings on the Modela bed. The Modela Player software on Windows was a little confusing to use, but after ~8 hours we had worked out all of the kinks.

Unfortunately I forgot to include holes for registration pins in my mold design, these were added manually by drilling through two stacked blocks.

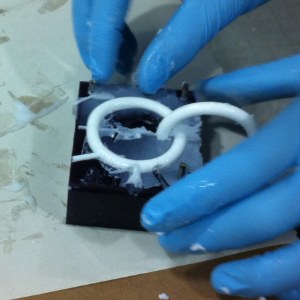

Casting

Casting was messy... I used SmoothCast 305 white plastic with a mold release to ensure nothing things wouldn't stick to the mold.

Final product

Linked rings!