I tried cutting the circuit out of vinyl. I used the highest pressure and slowest speed I could, whilst avoiding crumpling the wires. Even so, the knife cut cleanly only 75% of the time, making weeding nearly impossible.

I affixed my board to the Modela base with what I thought was plenty of tape. I was wrong. It cut the circuit fine. But when I tried to cut the outline, my board came free and destroyed itself before my eyes. I can't unsee it, no matter how hard I try.

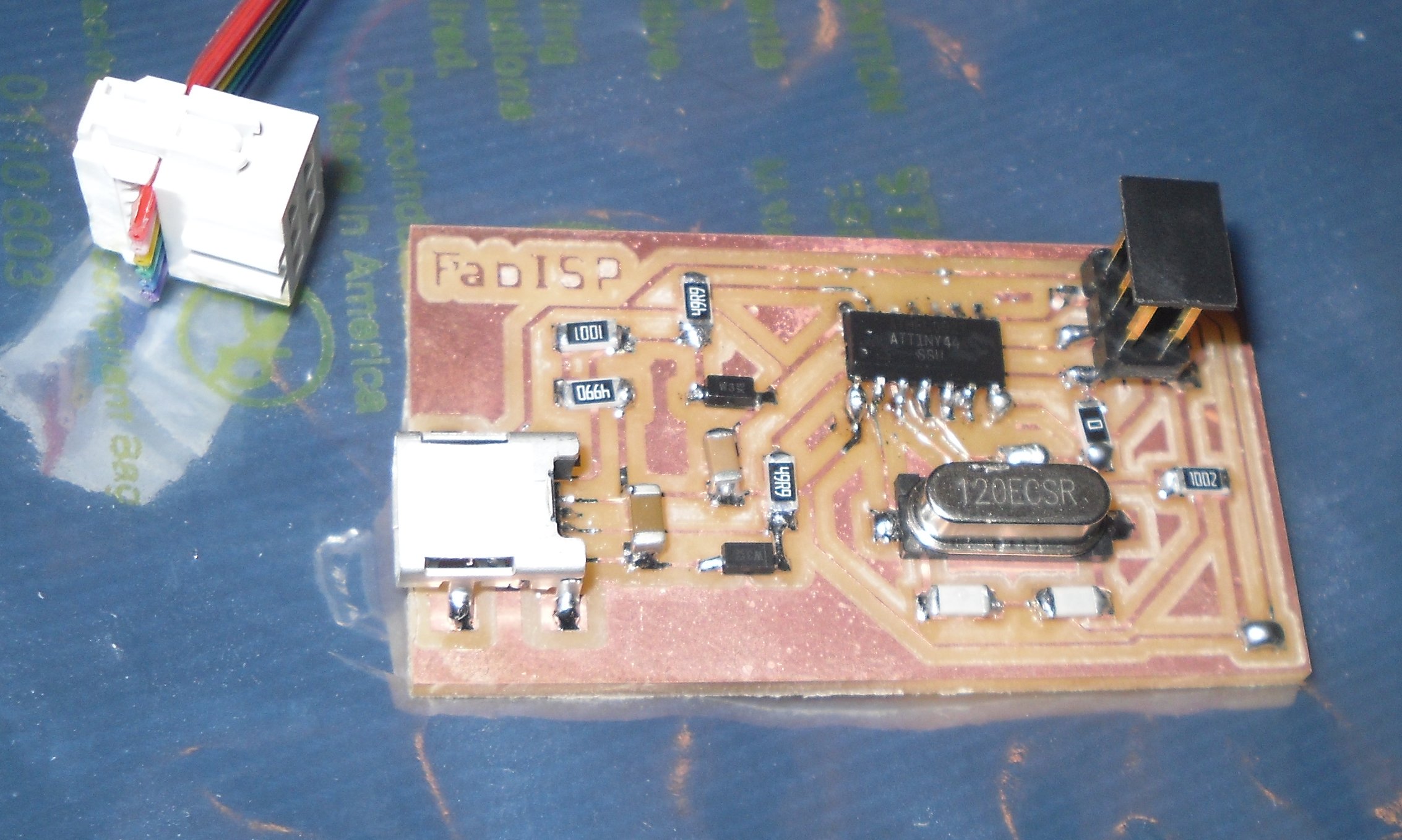

I weeded by milled board with a razor to clean out the copper that the Modela missed. But I didn't catch a microscopic wire connecting two of the pins of my controller chip (I literally mean microscopic - decimals of a mil). When my board wouldn't program, I meticulously checked for broken connections and shorts. After finding the problem, I had to lift my controller - a painstaking and terrible process. I accidentally lifted some of the copper connections too. Then I used a magnifying glass to find the culprit and cut it away. Re-soldering floating copper foil is tricky.