3)electronic milling

Assignment: make something big

"Press-fit 2way zaisu chair"

For this assignment, I learned

- a)how to use shopbot

- b)CAD (autocad & rhino)

What was hard for me was

- a)make close paths

- b)put a wood on the shopbot and remove from it

- c)screw on the wood

I planed to make a chair that I can use with a coffee table in my room.

I got a table in IKEA, but it was a little bit high for sitting on the floor

and using a computer on it.

Therefore, I decided to design a chair that I can use with a table.

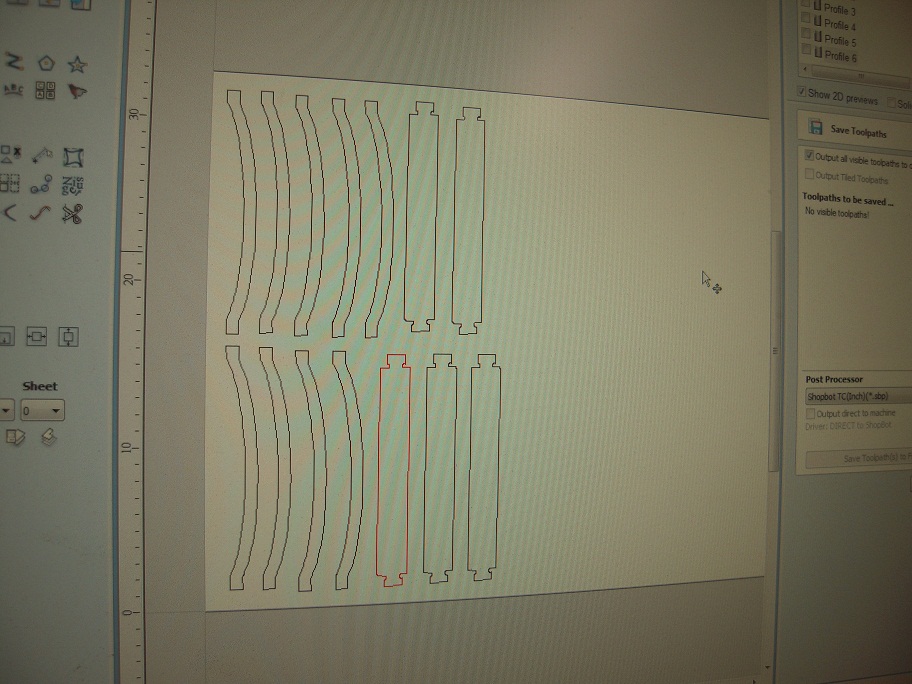

[Tutorial]

I did tutorial session to get used to using shopbot.

I already decided to make a chair, so I learned how to design press-fit parts

on Partworks and cut them with shopbot.

[Design]

The size of a chair was detemined based on the chair I am using in my office.

At the beginning, I started to design a chair with a inkscape.

Later, I realized that some paths were open, not closed and

it is not easy to connect one path to another with inkscape.

I was advised to use CAD to make it easy and started to use

autocad and rhino.

In those CADs, we have intelligent function "join" that guide

connections of paths easily.

To get confort on the chair, backrest is designed with curve.

For two way sitting, legs of chair can be removed: it can be

a legless chair to sit on the floor or a chair with legs.

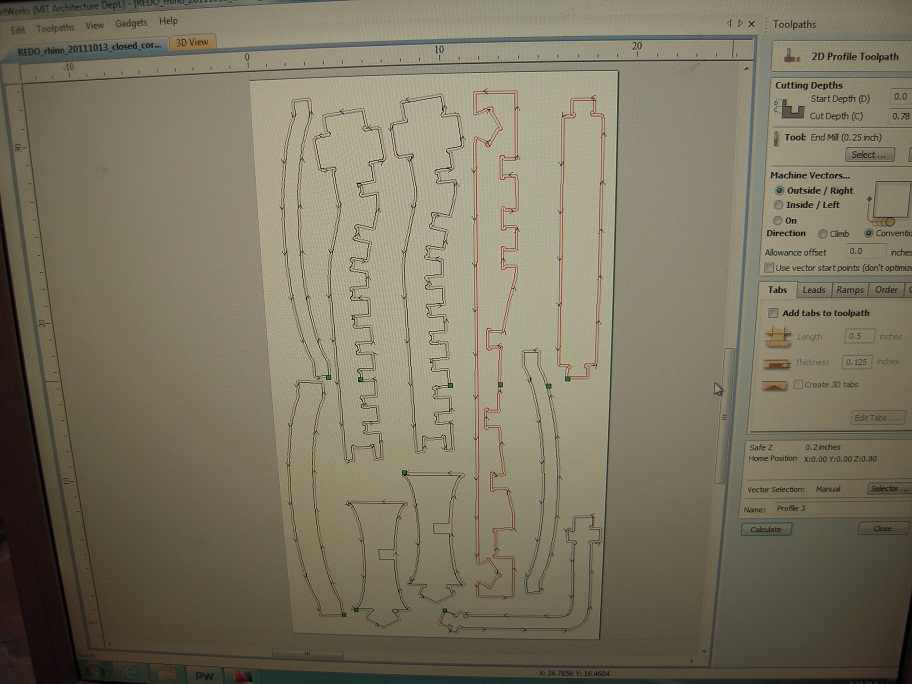

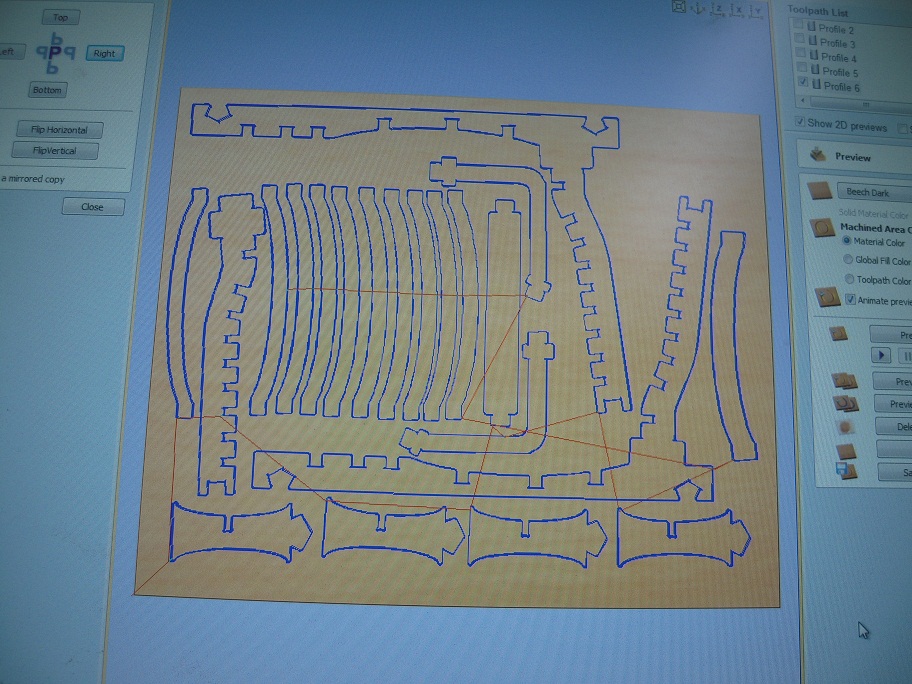

After designing with Rhino, I exported .dxf file to

open it on Partworks.

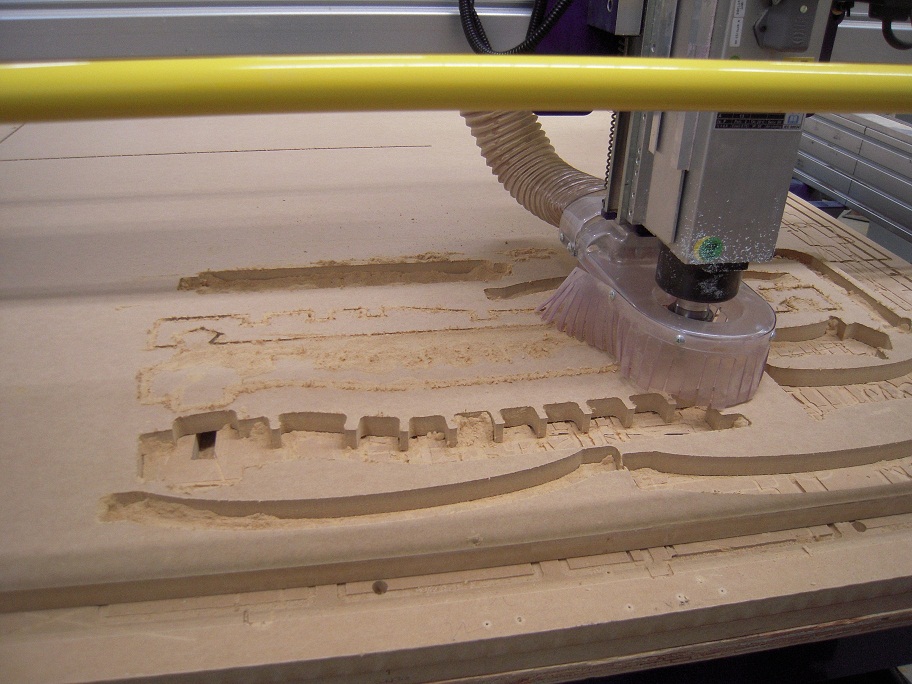

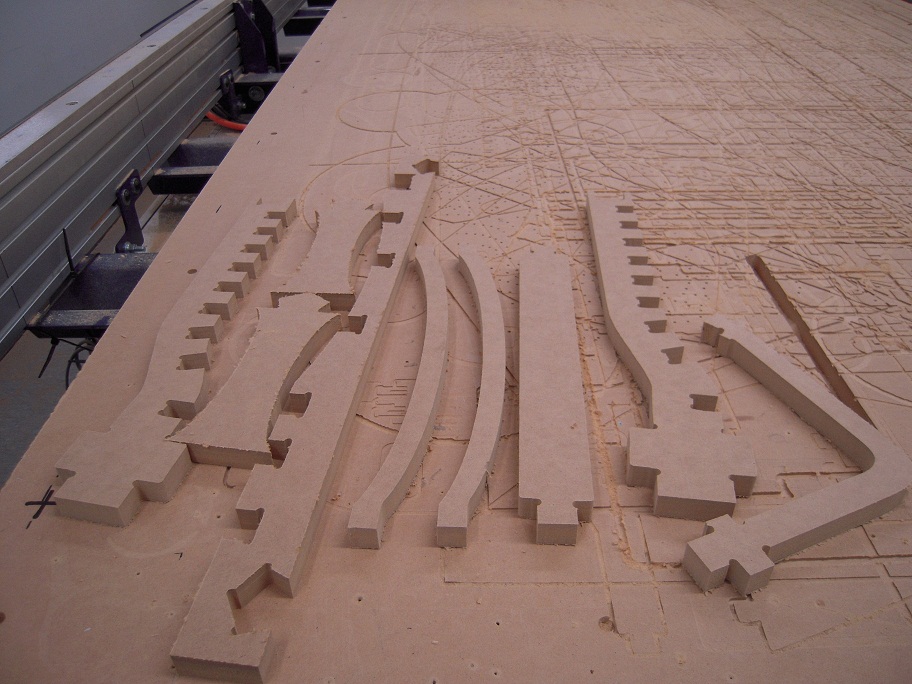

[Milling]

First, as trials, I tested some parts to confirm press-fit and

strength as a chair.

Joints between a base and a backrest might be too weak to hold weight,

so I changed design a little bit and connected a base with a backrest part.

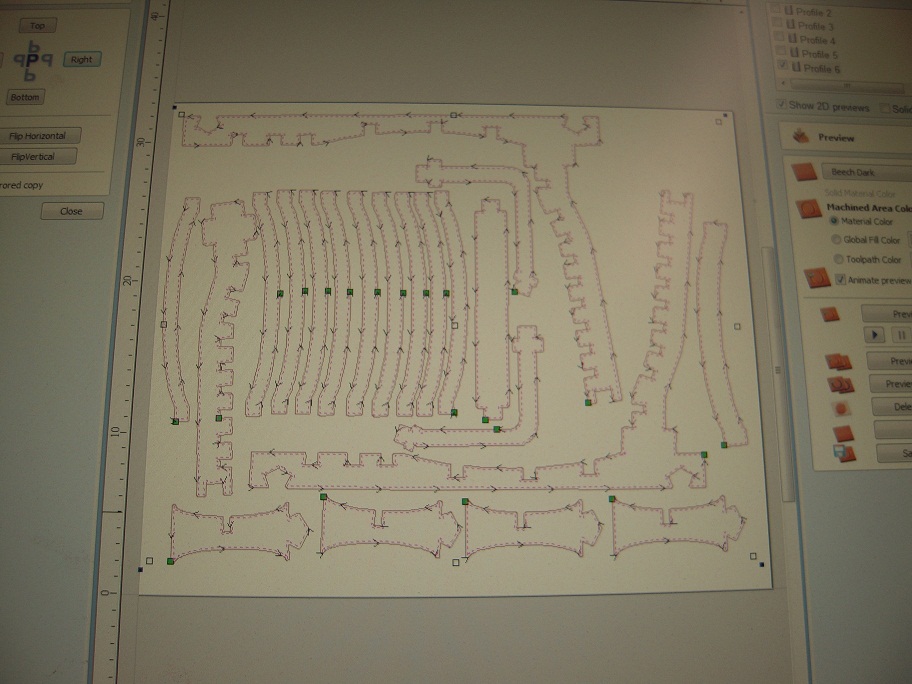

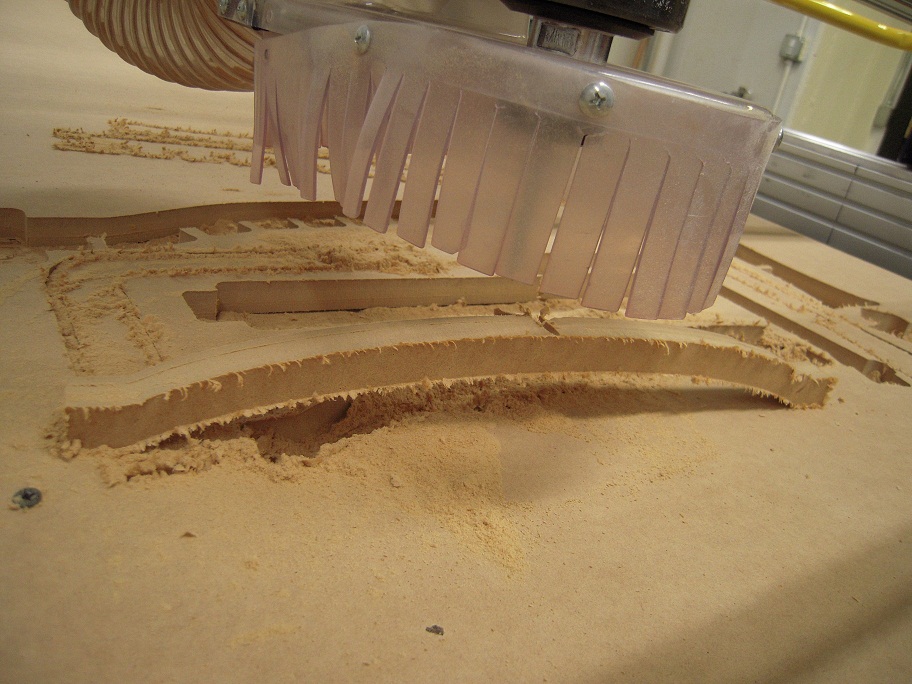

On the second milling, I had an another trouble.

Nested parts were located too close each other, therefore,

once shopbot cut one part, the part was popped up and it interfered

shopbot cutting another part.

I stopped milling, then made parts apart about one inch.

After cuting everything, made them press-fit(for some parts with a hammer)

and brought back home!

[Welding & Eagle]

This week, I also learned

- how to weld

- how to design an electric circuit with Eagle.