Molding, Casting, and Composites

Assignment: design a 3D mold, machine it, and cast parts in it

For this assignment, I learned

- a)3D modeling with Rhino

- b)Modela

- c)molding, casting & composite

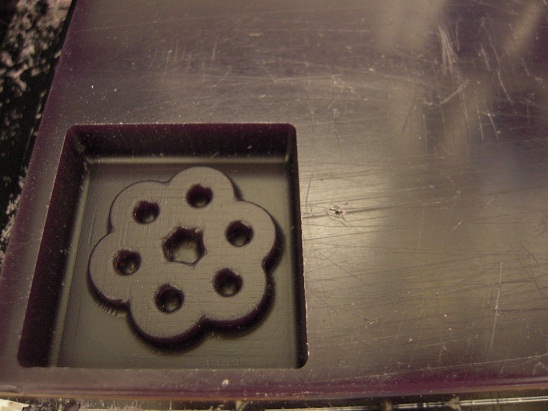

[Make a mold]

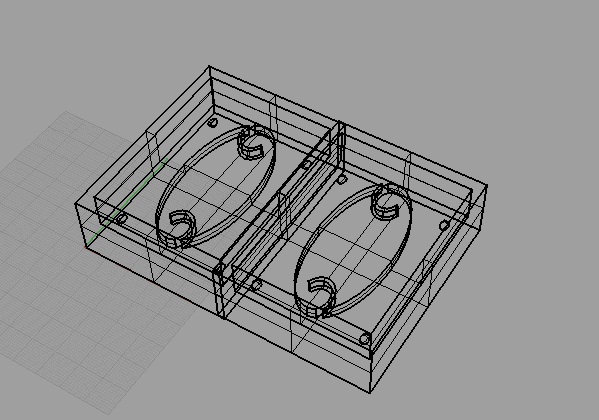

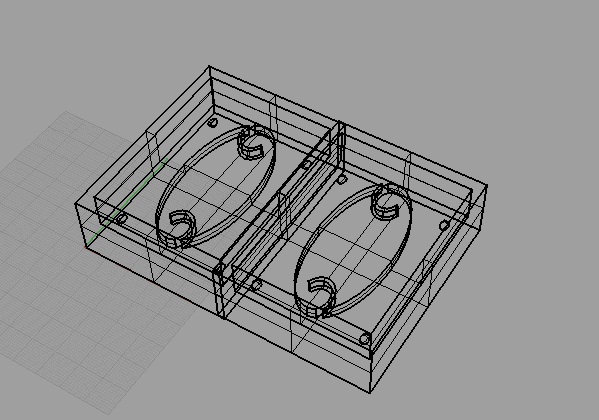

First, I planed to make some parts for my final project.

I wanted to make relatively soft cast, but eventually, I made hard cast due to

materials (hydro and dry stone).

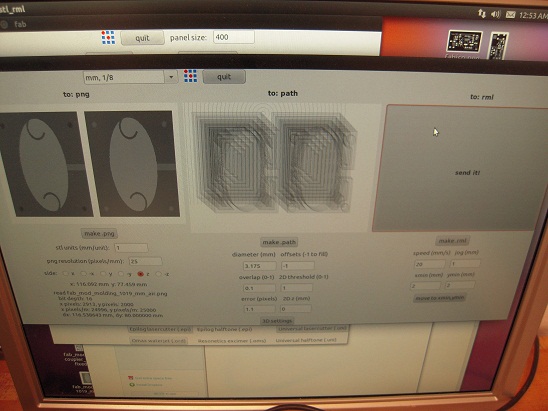

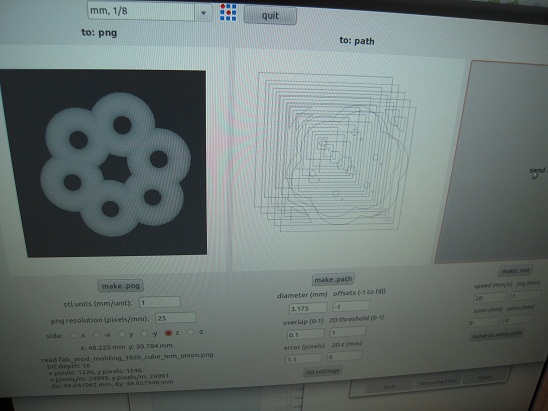

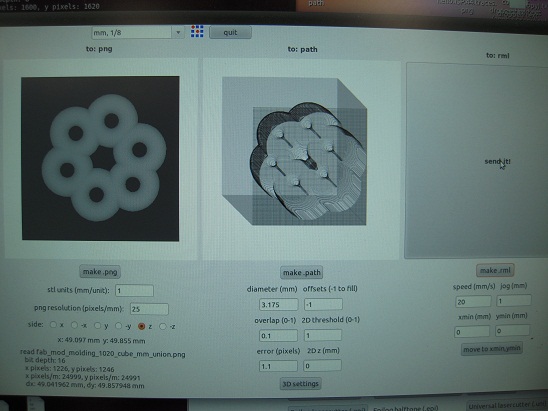

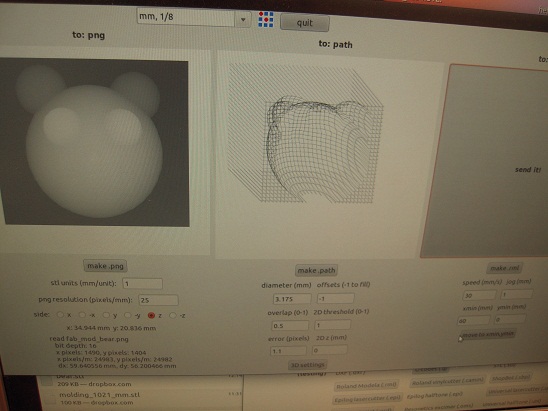

I started milling with too fine setting and two plots on the screen took

more than 3 hours to do rough cutting.

I set speed = 20, but z step was .5 that should be larger, maybe 2.0 was enough.

Furthermore,

holes I designed on rhino were too small for 1/8 inch mill.

I ran out of my time and could not do the final cutting.

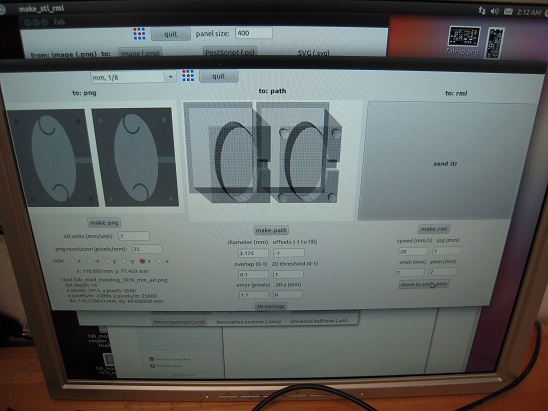

I also realized that I designed too boring shapes and decided

to design something with curves.

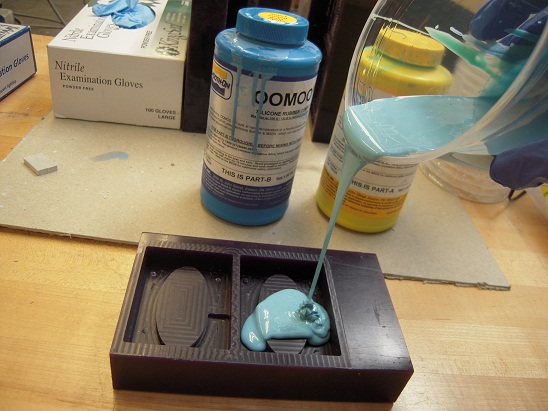

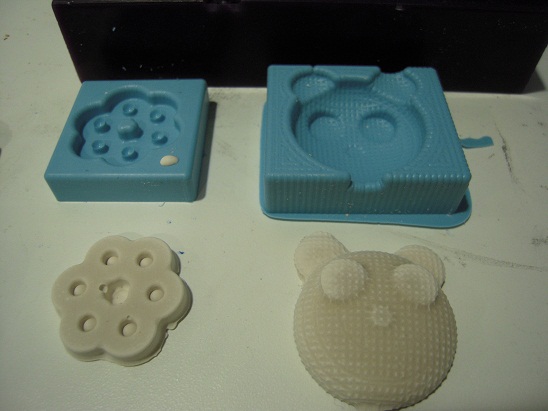

[molding & casting]

I tried hydrostone and drystone for casting.

Add water with powder (follow the instruction on the container for the ratio of water and powder).

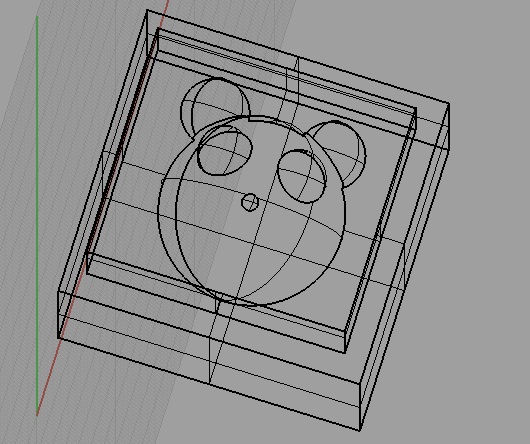

[2nd trial: make a mold, molding & casting]

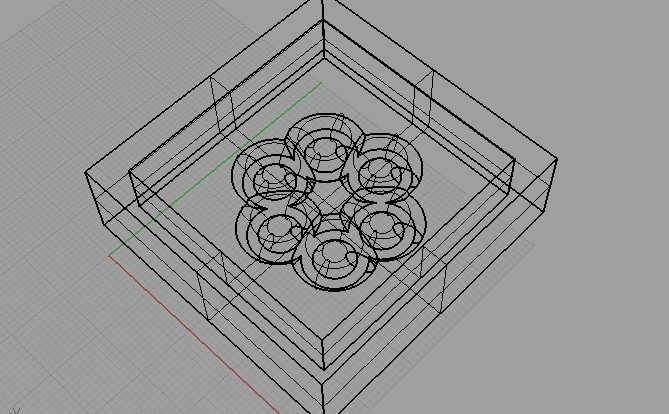

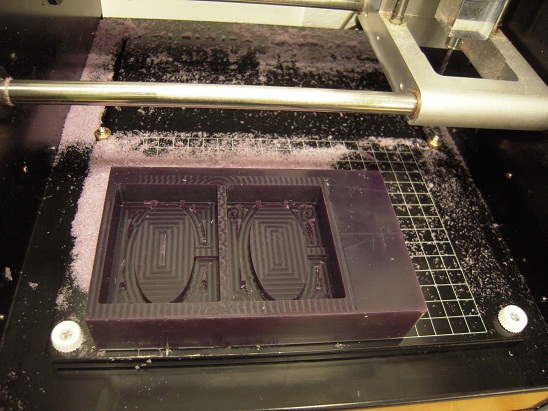

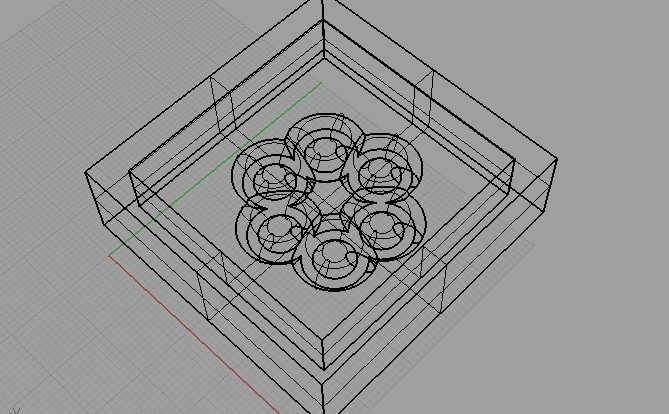

As the second trials, I designed combination with torus and cubes.

It also took me time to do union (combine torus and cube) on rhino.

Rhino repeadedly said "objects do not intersect".

It was because the cube was not closed...

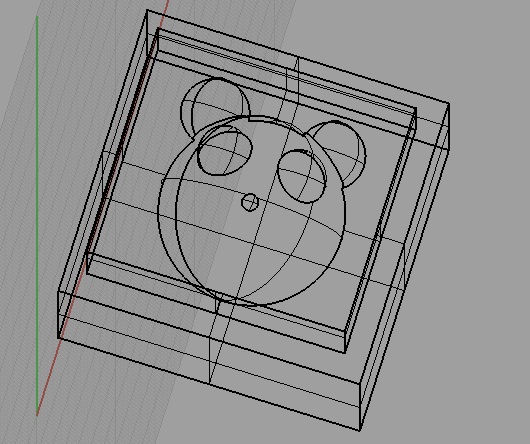

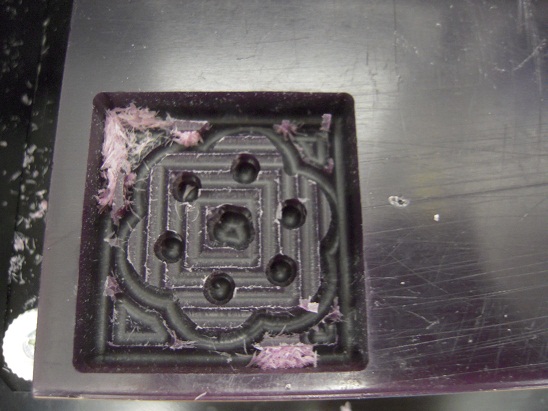

After rough cut, torus was far from smooth, but it became completely

smooth after the final cut.

On the other hand, a bear was still not smooth after the final cut.

Probably, I made mistake in setting overlap.

[composite]

After a composite tutorial, we tried fiber composite with drystone, hydrostone

and plastic.

Each of three parts were made of drystone, hyrdostone and plastic.