Assignment 1: Cutting Stuff.....

Overview:

Initially, I had high hopes of playing with geometries,

shapes and forms. As the week went on, the focus shifted to

evaluating tools and trying to get the tools to work.

As I started cutting materials, I also started experimenting with the

materials themselves.

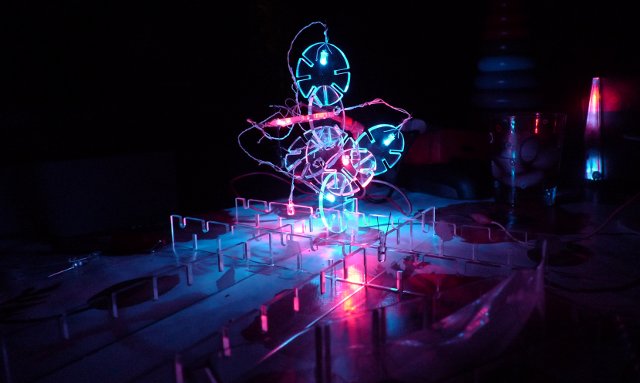

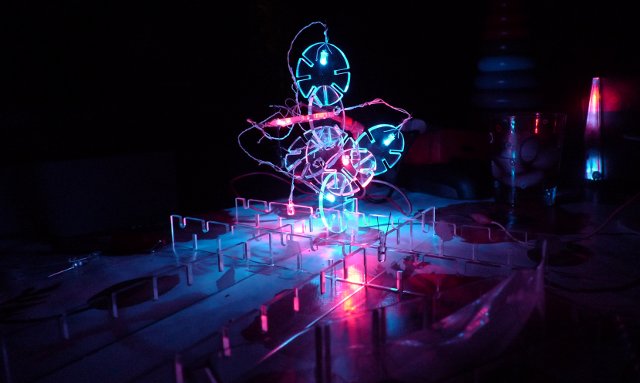

The final "product" is a lighting construction set, with a

walk through making motor mounts, and grids.

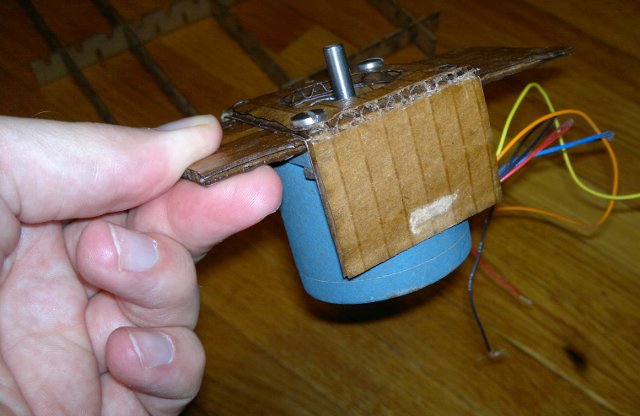

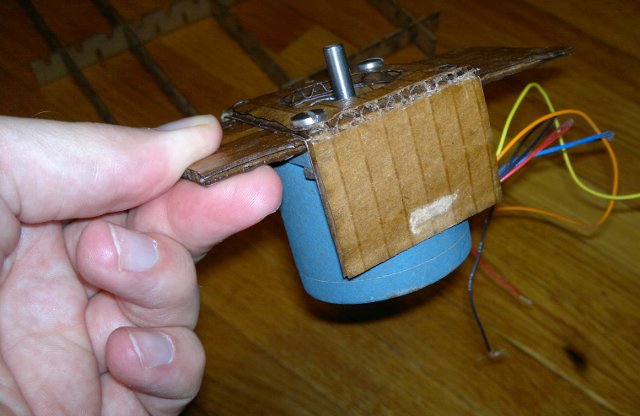

Experiment 1: Learning CAD, Experimenting with Cardboard and

Mounting Motors

Several of the 3D CAD packages had tutorials for

making plates with holes in them. I decided to make a

plate that I could mount a NEMA23 stepper motor to, out of

cardboard. Surprisingly, the center hole came out a

perfect fit to the face of the motor.

I was wondering if cardboard could be used as a low

cost material that could be used as a partial replacement for plywood

or plastic. Cardboard isn't strong enough to support

several pounds of motor, so I thought I would experiment with using

"Minwax wood hardener". This material costs about

$11/quart, and I used a couple of tablespoons for several cats on the

entire assembly.

This made the cardboard stronger, and looks pretty strong

the length of the ribs, but would buckle if I tried to bend it across

the ribs. Layering two pieces perpendicular to each

other may help. The assembly is weak near the

edges/corner. A better quality cardboard might also

help, or some better "wood hardener".

Conclusion:

- Wood hardener makes the cardboard stronger, and more robust.

- Two layers of cardboard with the ribs perpendicular will make a

stronger assembly.

- The corners and edges are not strong and will still crush.

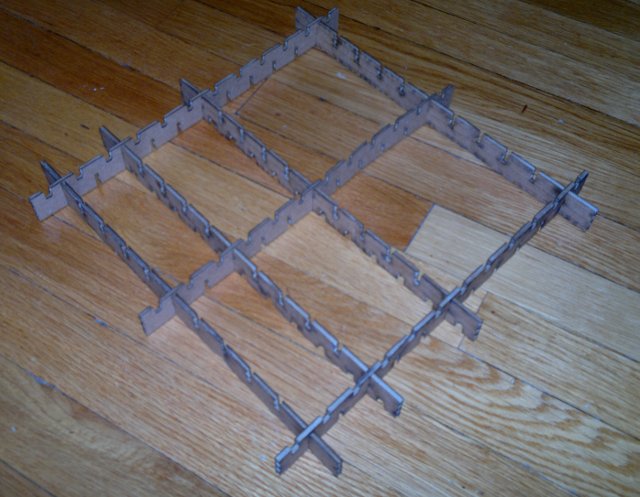

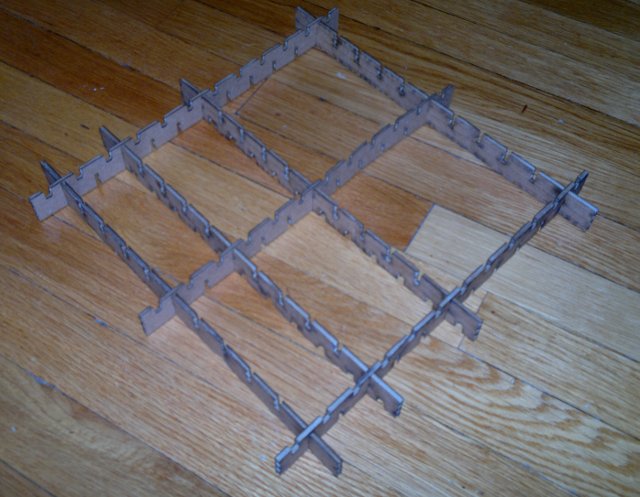

Experiment 2: Press-fit Pieces

Next I tried to make cardboard pieces that would fit

together in a grid, with an eye towards extending to more complex

surfaces. (With the hope that it could be used

to make a construction kit that would allow making structures/surfaces

for prototype furniture.) This was successful, although the

laser-cutter would make multiple passes over the lines several times.

Setup and cutting time was long, so I only made a handful of

pieces.

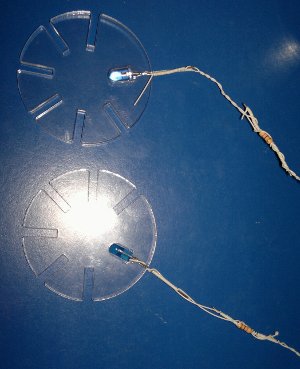

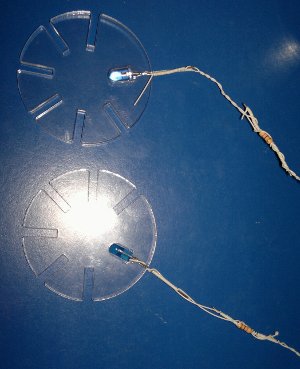

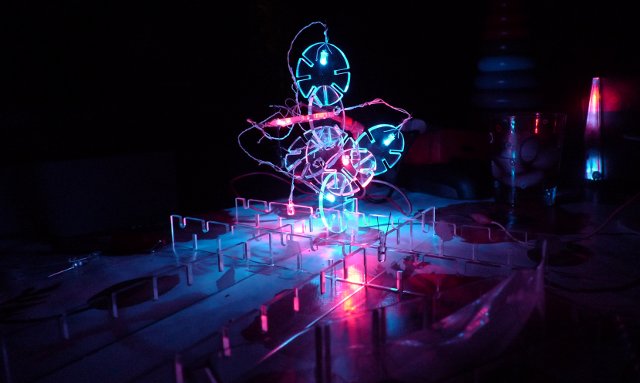

Experiment 3: Lighting Construction Kit

The press-fit pieces made me wonder if they could be used

as a multi-segment light-pipe. I resized the strips for

acrylic, and made a circle with slots that could be assembled at

angles. I cut holes to embed an LED in the pieces.

To not violate the "no adhesive rule" of the assignment, I

used a "Star Trek Captain Kirk would be proud" slit and wrap wire wrap gun.

When used with proper wire-wrap pins it creates a MIL-Spec gas tight

joint that is very reliable. I had problems with

the LED pins being too round (the wire-wrap pins are usually square)

and too thin, so I crushed them slightly with a pair of pliers.

The LEDs are powered off a USB battery, and a 330 ohm

resistor is in series with the positive lead of each

LED. (Looking at the LED, the smaller internal part

is the positive.)

Results/Lessons Learned:

- Acrylic isn't the best choice for press fit pieces.

Too tight, and it cracks, too loose, and it does not stay.

Try it too many times, and it scratches.

- Sheet acrylic varies from piece to piece and end to end in

thickness.

- CAD -- Parts seem to deteriorate when I cut and pasted

them. Details seem to get dropped from generation to

generation. This could be my lack of cad

skills. There may even be variances from cut to cut.

The Final Result:

Future Ideas:

- Add more shapes

- Figure out better acrylic/led mounting.

- Think about adding contacts to slots, so that the thing wires

itself.

Implementation notes:

The majority of the files ended up being drawn on

Inventor, and exported to Autocad. This resulted in

3D models in Autocad, and the laser cutter would cut the lines multiple

times. This may have made for wider kerfs, and made

plotting very slow.

Notes on using the Epilog 60 laser cutter.

The kerf through acrylic is .159-.138 = .01 inches

per cut (2 for a slot.. i.e. .02 inches)

For cardboard it is .172-.133 = .019 inches

per cut (2 for slot, i.e. .039")

This may be with the multipass bug in my cad

files... Not sure.

Using Inventor, and chamfer of .03 on openings of

slots for cardboard.

So for .125" plastic we will try .108ish slots,

which are too narrow for the power settings I used. In the

end, I ended up setting the slots to .125"

Copper foil with backing .006" (for conductors

later).