This week:

Network:

Hacked some of my existing boards to try to run Neil's

serial code. Looks like I may have cooked a board or have a

loose connection -- the small one doesn't want to program this week.

The working one seemed to be responding. Will

look more when I have a little time.

Boards of the week:

This week I drew up some more motor control

boards...

The first ones, I was going to use a

compatible chip (DRV8811) to the A3977, but it may actually a

compatible chip to the A3979, which comes in a much smaller

package. Oops.

Then I made an adapter board for some older

monolithic motor driver chips, so that I had something for the short

term. They will be hooked to the microcontrollers with a

ribbon cable, so I can swap back should I build an IC level solution.

I also relaid out the 8 channel MOSFET board

with SMT logic level

FETS. It is shown here, and should drive some unipolar

motors.

Flexure Discussion:

As Neil suggested, I found and talked to a

researcher about flexures (doesn't MIT have a researcher for

everything). They work awesome for very fine

positioning. Typically they use a force driven

actuator... (i.e. voice coil/electromagnet). The

downside is that the assembly is about 10x the size of the workspace --

i.e. a 1 inch cell would yield a 10 inch

assembly. They sound cool, but I was thinking

of stuff on the more macro level (inches of movement).

He also made interesting comments about how I might make

various positioning assemblies (pros/cons of cable v.s. belt v.s.

screw, and where to put bearings), and suggested making some

air-bearings. Overall a fun conversation.

Final Project:

The Origional Grand Plan: Automate the world!

The initial plan was to build a toolkit of hardware/software for

building machines. The idea was, since it was a

toolkit, it should lower the bar to building various

machines.

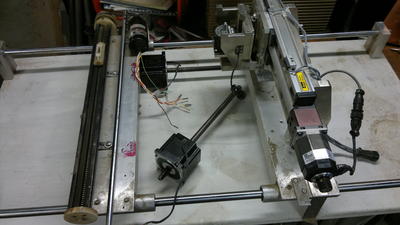

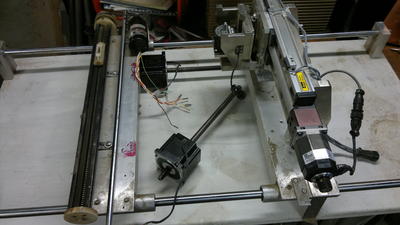

Here is a sample of the parts I have around that I was thinking could

be converted into a pick-and-place machine, cnc router, solder paster

dispenser, or all of the above would manufacture a PCB.

Status:

- Screws are ordered but won't arrive until late in

the week. Don't have driver solution for large

motors yet.

- Large stepper motors is stimeyed by the small pitch parts...

(htssop package)

Home stretch plan:

-

Reduce Scope: Look at completing the 3D scanner.

Todo:

- Add axis for Z.

- Fix USB-Stepper code to be more robust and spin the motors at

stable speed.

- Calibrate and fix geometry code.

- Complete multiprocessor solution.

- Figure out STL/output

- Optional:

- Build sexier stepper drivers

- Make it do something else cool.