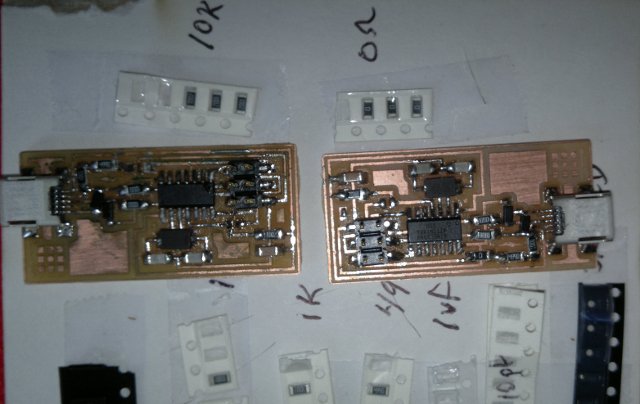

AVR Programmer... Building...

Taking the reference design from the class

page (directions are at the bottom), and the wisdom of my

classmates, the routing of the board was straight forward, with a

slight adjustment of cutter depth. I washed the board with a

scrubber pad I found near the sink. The board seemed a little

rough-- it seemed like the cutter tore the copper more than cut it.

In stuffing, there were some shorts on the USB and programming

connectors. A meter looking for +5V on the 1uF capacitor showed

the board wasn't getting power. The USB connector cleaned

up with some careful solder wicking.

In programming under Linux/Ubuntu I followed the directions.

The software seemed to allow setting of the fuses on the

first run, and then complained that it couldn't talk to the target.

After checking for bridges, resoldering stuff, I built up

the second board, and had the same problem.

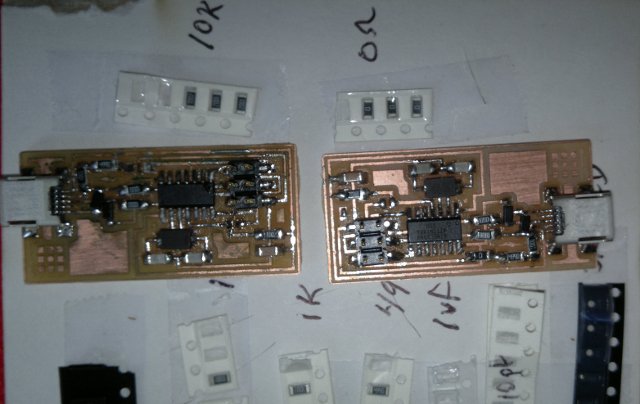

Finally, I pulled off the pin header to double check for bridges.

No solder bridges were visible (either looking while looking

under the connector, or once it was pulled. I took a knife, and

carved between the pads to remove any little strips of copper that may

have been left. When I resoldered the connector, it

worked.

Little bits of wisdom gathered....

- The "Z" value (cutter depth) on the fab module needed to be set

deeper -- from the .1 or .2 recommended to .4

- The cuts of the board seemed a little rough. Maybe

sanding the board a little would have helped.

- Check for +5 volts when testing. If it isn't there,

then there is a short.

- A quick scrape between the pins with a knife might have helped

with shorts.

- The flux pen made it easier to solder.

Other minor discoveries/projects...

- Played with Eagle, ordered parts for motor

controllers.

- Inkscape will generate gears! Need to

try out on the laser cutter.