Make Something Big...

(Battle with the Shopbot)

Our house has tower. An absurdly small tower. A

chair won't even fit. These are the steps up to the tower

-- very steep. These stair also function as a

skylight for the upstairs hallway.

As an attempt to make the space usable as a reading nook, I put in a

bench. I was inspired by a design encyclopedia by a bench that

is made of slats of wood. I was also inspired by the

plywood box stools up in the Arch shop.

For this assignment, I wanted to build a shelf/armrest to keep people

from falling down the stairs while using the bed.

The wood I selected was marine grade

Merranti

A/B -- Merranti is Philippine mahogany.

It splinters a bunch, but it is very strong.

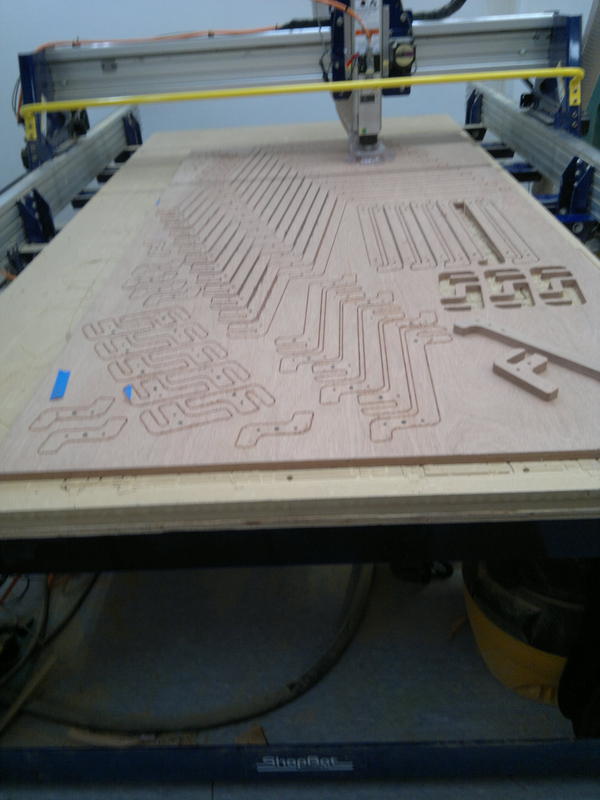

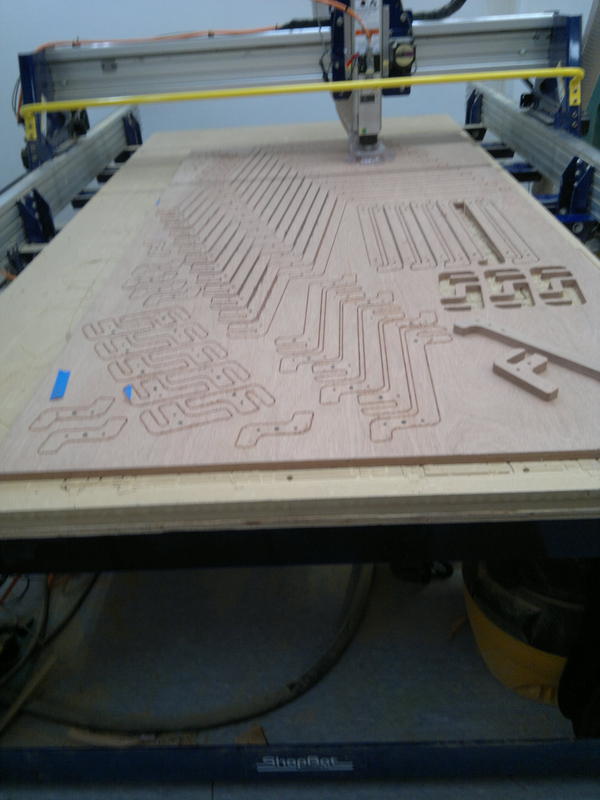

This made for a sheet of pieces.

Shopbot settings were: 1/8" 80 speed, 60 plunge (inches per minute) .5"

cut 18k RPM on a 2 flute 1/4" shank end mill.

Initial pieces were cut from scraps from MDF for fit.

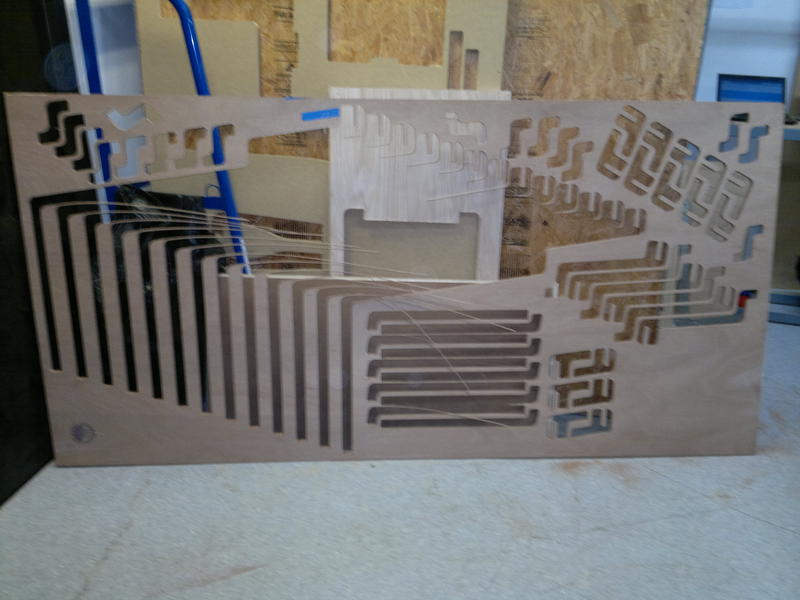

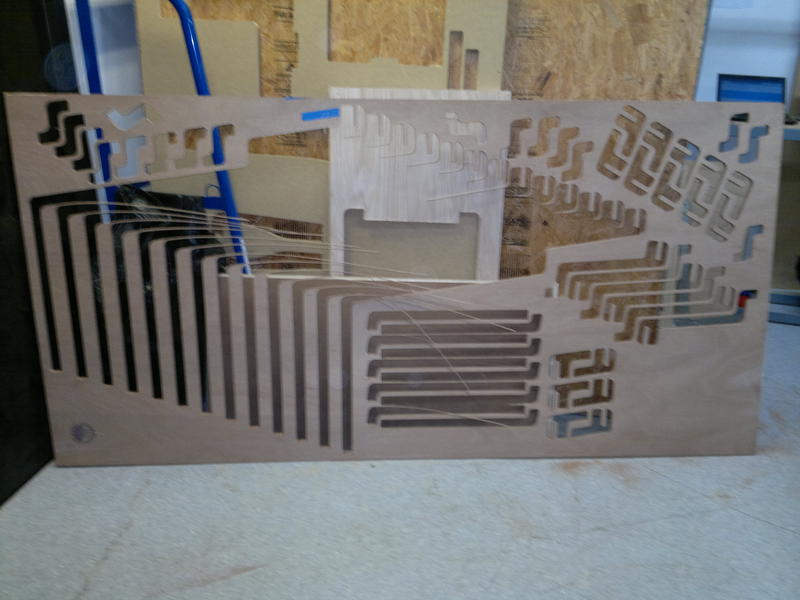

The final pieces were cut from one sheet. Once they

are finished, the pieces will be stacked and attached to the wall.

Lessons Learned:

- Learning a new tool takes a bunch of time (over 20 hours spent

with the machine)

- Learning new software takes a bunch of time. (Thanks

Shaul, Felecia, and everyone else)

- Material and tools get hard to get at the end of the week.

- A backing board might have helped with chipouts.

Super special

thanks to Moritz and Felecia for their help! I wouldn't

have been able to do it without you!

Other:

- Played with Eagle. Added pushbutton and LED to the

fabisp programmer schematic and board.

- Played with Boxmaker

when I thought making the shelf would be easy.

- Command to resize a directory full of images: find . -iname

"*.jpg" | xargs -l -i convert -quality 75 -resize 20% {} output/{}

Final Project:

The Ideal:

Ideally, I want to make as many of the machines we have

used in class as I can.

This could include:

- CNC Mill

- 3D Printer

- CNC router (mini shopbot)

- 3D Scanner

- Pick and Place Machine

- Vynal Cutter

- CNC Lathe

- CNC Shaper

Sound impossible, it probably is!

Approach:

Many of the machines have the same architecture -- a

2D or 3D positioner and a tool. I have collected over

the years many mechanisms including:

- Rotary Table

- Motors

- Linear rails

- Linear positioners

- Tools

- Machinery

- Electronics

So what will I really be doing:

- Evaluating the commonality of the approaches, and where the holes

are from a variety of perspectives. (i.e. what can be

leveraged from OpenSource Tools, what are the software toolchains like,

what need do I have, what needs to be built?

- Trying to assemble some of these mechanisms into machines.

- Building mechanical interfaces between the pieces.

- Developing motor drivers, electronics, etc

- Control software and software integration.