Casting...

I was out of town this week, so I wanted to cast

something that could be useful for my final project

ideas. So I tried to make a motor shaft

coupler. With leftover material, I also cast a section of

tin ceiling tile, a plotter pen holder, and a gear-belt pulley.

Process:

- Draw part in Inventor,

- Import into Rhino, and put

the box around it.

- Select part, draw boundingbox

- Draw diagonal line across the center (to make sure scales flat

in all dimensions?)

- Select box

- Scale 1.25

- Select box, explode, select top and delete

- Milling wax on the modella.

- Rough Cut:

- Speed (through wax) 20mm/sec

- 2mm deep

- Finish Cut:

- Cast with blue rubber

- Oomoo -- Equal parts A&B by volume

- Mix, mix, mix

- Demold in 75 minutes

- Moldstar 15 slow

- Spray parts with mold release

- Equal parts A&B by volume

- Mix, mix, mix

- Demold in 4 hours.

- Cast final object.

- Drystone

- 18-20 parts H2O by Wt. (20 Grams)

- 100 parts Drystone (100 Grams)

- Add half of the powder, let soak for 2-3 min,

Mix, add the rest, mix, mix

- Demold in 30 Minutes

- Machine within 2 hours of demolding.

- Hydrostone

- 18-20 parts H2O by Wt. (20 Grams)

- 100 parts Drystone (100 Grams)

- Add half of the powder, let soak for 2-3 min,

Mix, add the rest, mix, mix

- Demold in 30 Minutes

- Machine 2-4 hours after demolding.

- Try to cleanup parts on lathe.

- Six jaw chuck holds Drystone/Hydrostone parts ok.

- Stuff tends to chip, or in some cases break.

How it happened:

In importing the part from Rhino to inventor, the units

got lost. Eventually (with help from of one of

the lab TA's I managed to get a part of the correct size.

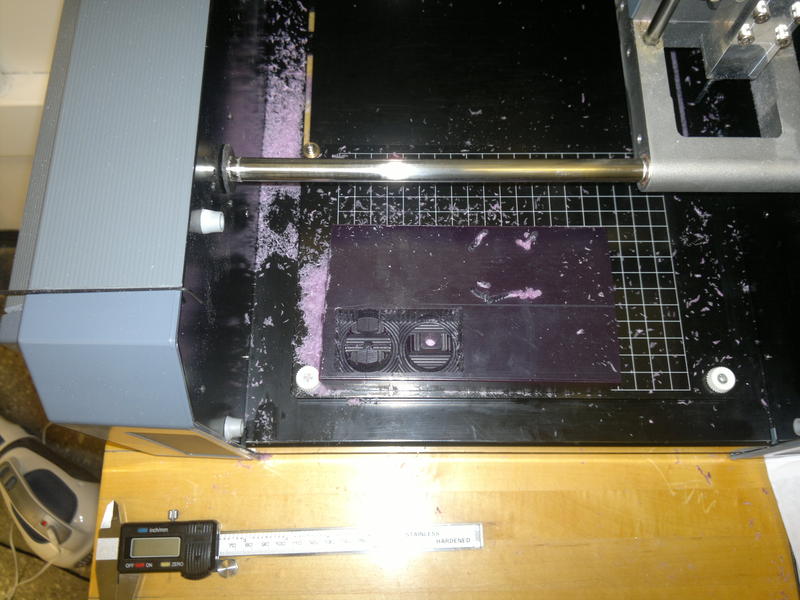

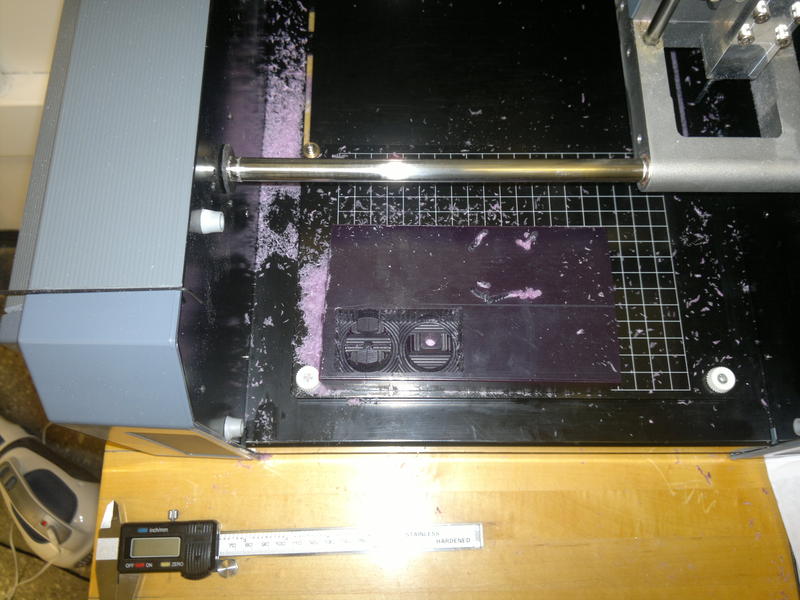

Milling on the Modella, the initial rough cut took close

to an hour. I then spent a few hours playing with final cut

parameters. The final cut still appeared rough, and

may have made the critical surfaces of the master

rougher. Initially I used a ball mill,

but moving to flat mill made only a limited difference.

The camm algorithm in the Fablab modules seem to

take a

pretty simple approach, and does not follow the features of the part

carefully (to produce fine details). (i.e. circular

patterns not in it's preferred plane come out striped.

Molding one half of the shaft coupler ended up with an air

bubble in the shaft hole. Didn't mold cleanly.

The hydrostone/drystone are much stronger than other

plaster-like substances I have worked with in the

past. They do machine, but not real well. I

tried drilling and facing. Parts are brittle, and the powder is

probably bad for the lathe. It is a quick/cheap way

to verify that the parts came out ok.

Thin tabs/features tended to break off.

For the parts I'm building, the thin parts that broke didn't matter.

Other:

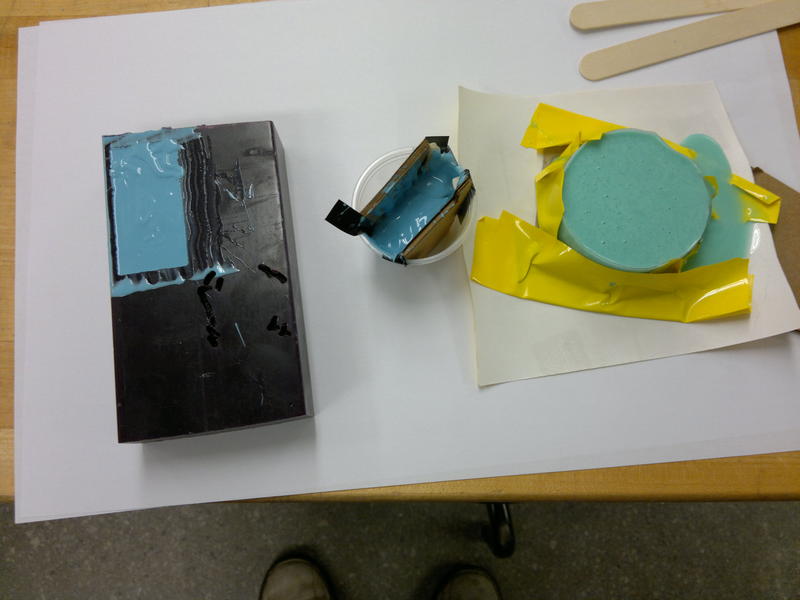

I had extra casting material, so I tried to reproduce a

pen holder for my plotter, a gear belt pulley, and a piece of our

kitchen celeing. The parts are shown below.

The pen holder was doing ok until the lathe... then it

split apart.