Making more boards, and writing a little code....

This week, I had the usual assortments of things

taking longer than I thought they would.

Accomplishments:

- Late night panic, and developed a general purpose ATTINY44 board

that is based off of the FABISP.

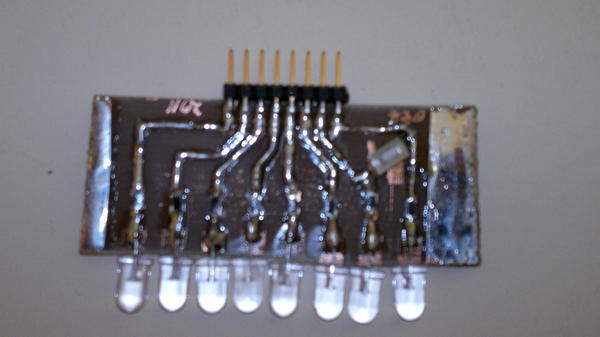

- Developed a plugin light/switch paddle board for the above.

- Wrote/burned a little code to make the LED's do something.

- Got my GPIB plotter working, making PCB's and etching.

- Drew up a revised fabuino board with a ATMEGA169 (that has a

short)

- Tried more casting with the shaft coupler, gears, and pen holder

of last week in urathane.

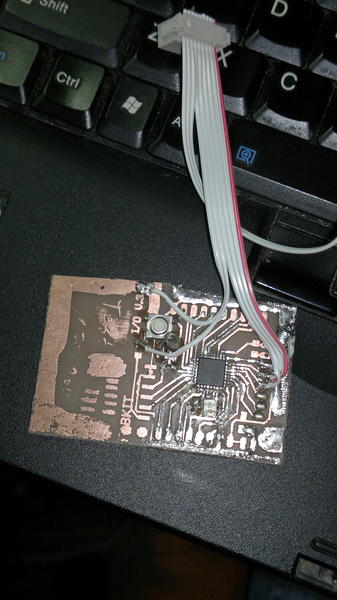

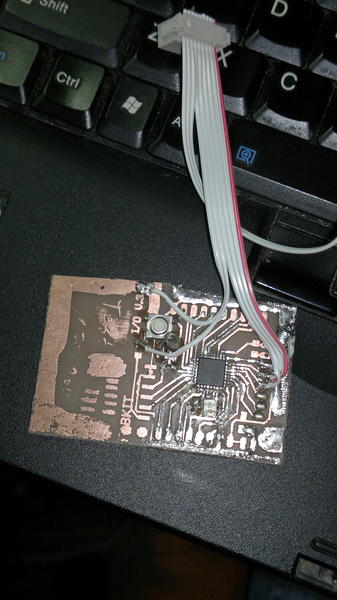

ATTINY44 General Purpose PCB

I wanted a board that I knew would work, so I modified the

fabisp board to break out all of the pins on a header, put on the PCB

usb connector, and a programming connector.

And assembled....

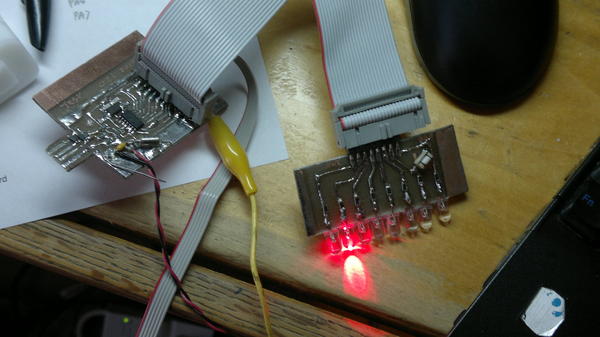

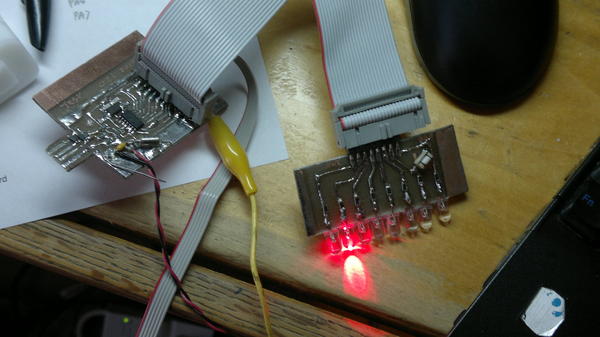

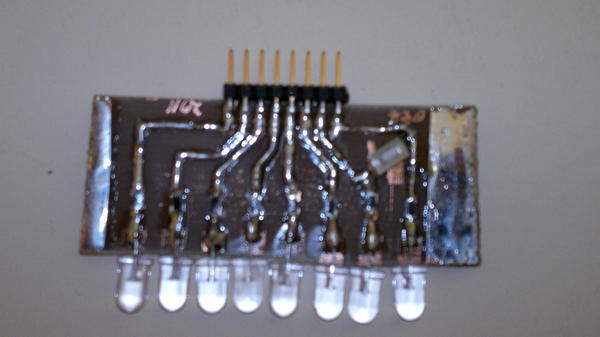

Attached to that board is a LED breakout board with a

button. This could be swapped with other boards with other

types of functionality. It is shown with a little code to

blink some LED's.

Fabuino Mega168 Board Attempt

Assembled, but there is a short on the reset line.

Will need to debug. Time to spend more quality time

with the microscope!

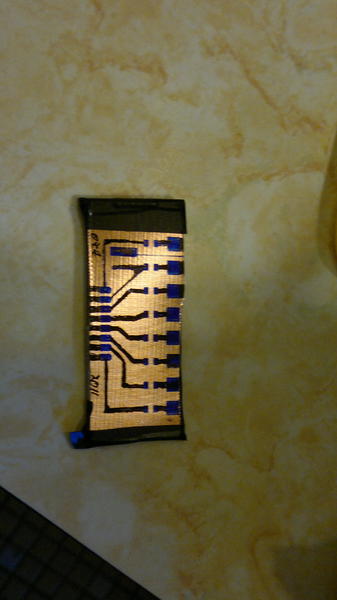

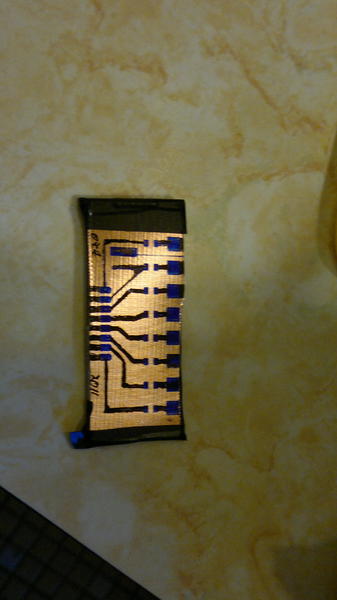

Making PCB's

Much of my time was spent trying to remember how I

used to make circuit boards on an old pen plotter, and experimenting to

see if I could make boards of comparible pitch and quality to those

produced on the modella. This would have two advantages--

the process can be faster, especially for larger boards, and I wouldn't

have to spend late nights at the lab making boards.

Unfortunately, the PC I had that would talk

GPIB to the plotter, decided to finally die. After some

fighting I upgraded it form a 386sx to a k62-233 (I needed an ISA

bus)! Woohoo...

The process is as follows:

1. Scrub board with brillo....

2. Plot board...

3. Mask areas, and touch up artwork...

4. Play with fun chemicals... (FeCl) The board is in a

ziplock freezer bag, and I swish it under hot water in the sink for

about 3-5 minutes.

5. Scrub the resist off with brillo, and populate! (See

above)

Results:

I was getting pitting on the

etches. I think it may be due to using a blue pen

instead of a black pen--places I touched up with the black pen eld up

much better.

Casting with Urathane

I tried casting parts with Alumalite (white) hoping that I could

machine, drill and tap them. Turns out I should have

mixed the bottles better. The first parts came out a

little soft, the latest batch came out foamy because I shook the bottle

before mixing. The finished surfaces on the foamy

parts came out ok, but they foamed up on the back side of the

part. Try, try, again!

Notes on Embedded Programming Assignment

In the FABISP

makefile, there is a change required to use the FABISP instead of the

Atmel one.

Under the microscope, I could see a sketchy connection

(and maybe I forgot to install a jumper) so both programmer boards now

function!