For this assignment we had to machine a mold in machinable wax, then cast the negative in

silicone rubber

and finally the positive in dry stone

or hydro stone.

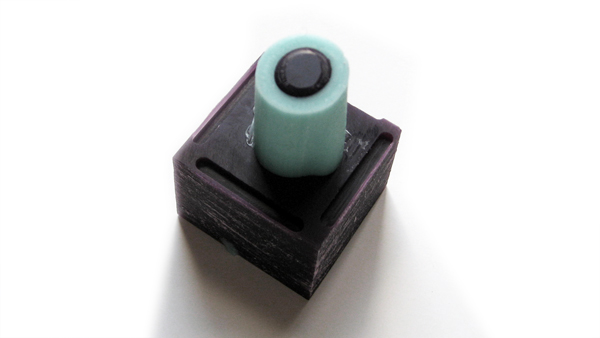

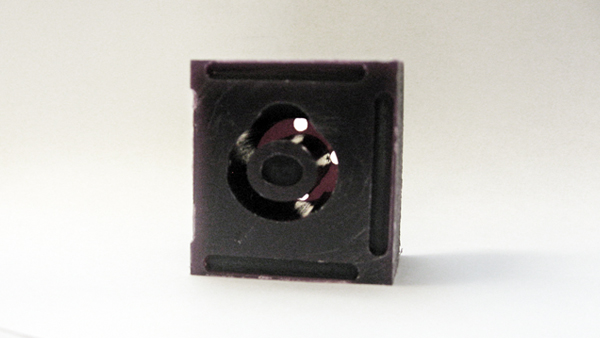

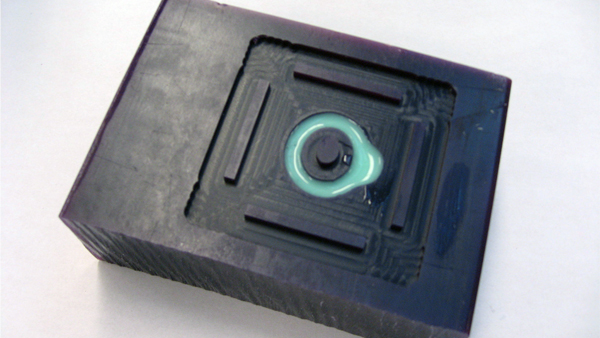

I decided I wanted the final outcome to be flexible so I use the machinable wax as the negative mold and then I casted the final outcome in silicone.

This exercise is a step towards my final project. I want to restrict finger movements and then control through feedback. I will need to attach "things" to my fingers and these flexible covers will help me incorporate that.

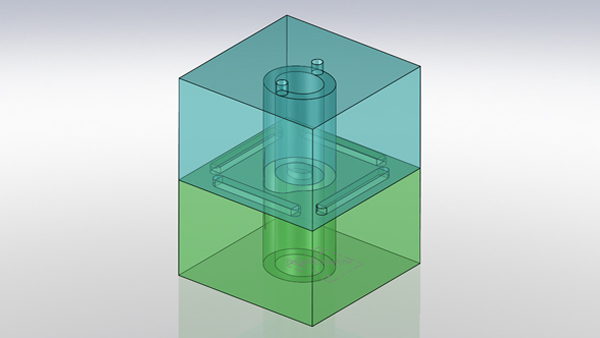

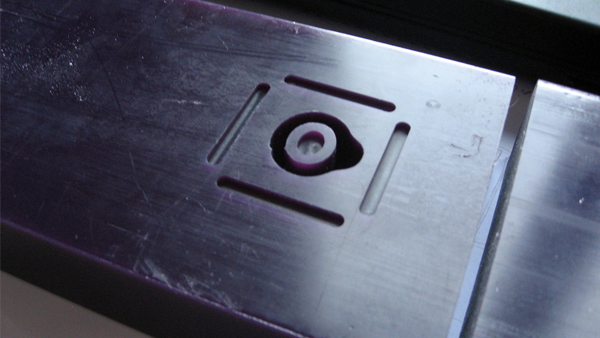

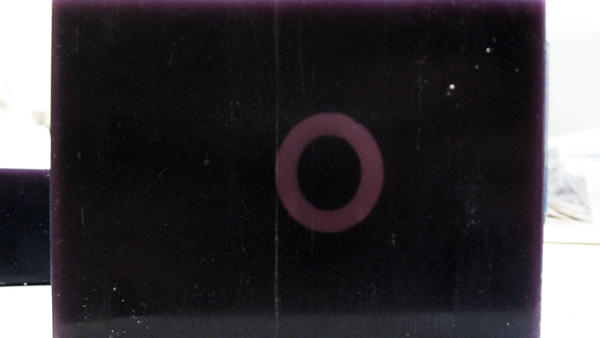

I designed a positive 3d Model in Solidworks and then use Boolean operations to generate the final negative mold to be machined. Everything is parametric so I can come back and fix the problems I found after fabrication.

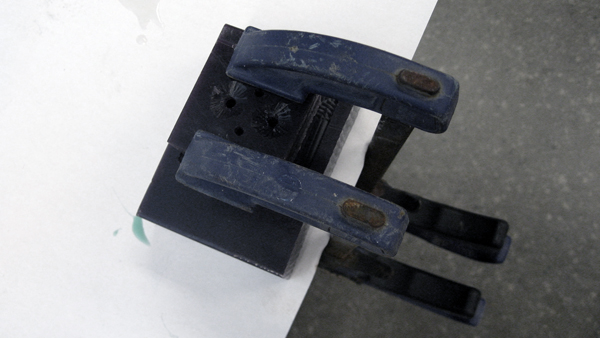

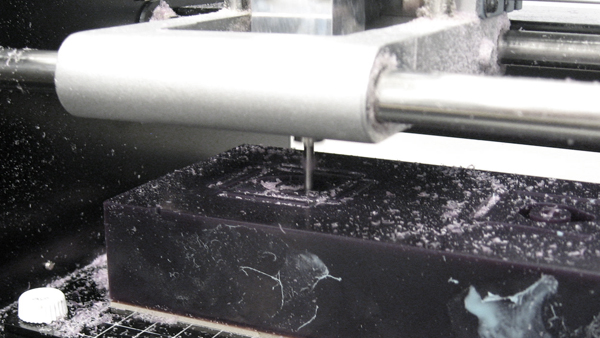

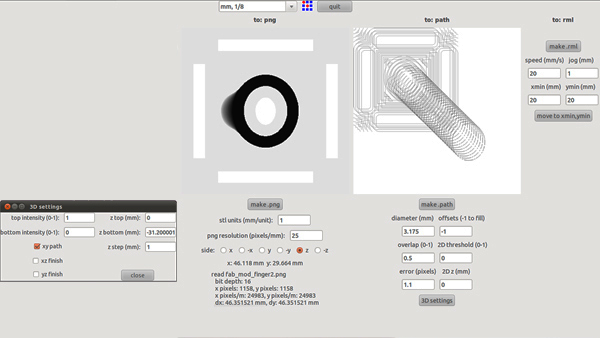

We used the Roland Modela milling machine and the

Fab Modules to machine the mold in wax. It worked well, I just had to set up the Z height of the bit so that it can machine all the way through the material. I had to use a sacrificial layer to protect the machine.

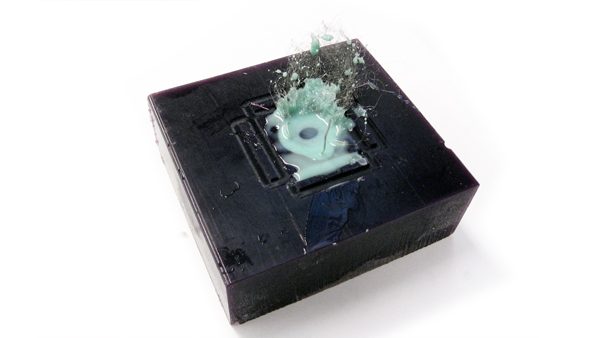

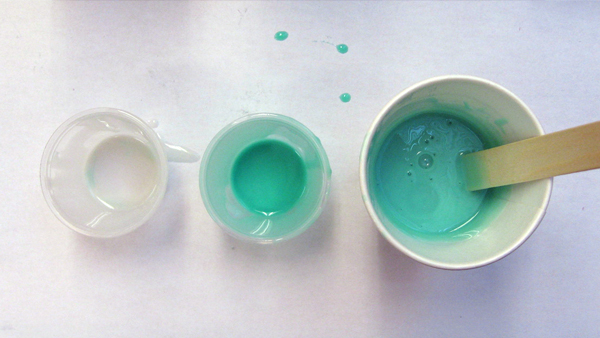

It was suggested to use silicone rubber which has 15 min. of pot life and only 45 min. of cure time. My mold was very small so I decided to use a slow type of silicone rubber which has a lower viscosity and 50 min. of pot life and 4 hours of cure time.

The process of filling the mold involves mixing, dearing and pouring and dearing again and again. I had a lot of problems because my mold is very deep and the pouring holes very small. This is way it was important to have enough time to complete the process.