(

)

)contact // irina chernyakova

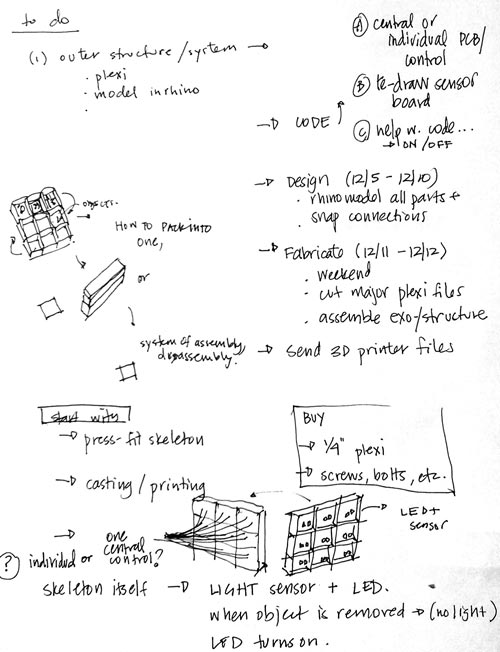

1 [0912] FINAL PROJECT PROPOSAL 2 [0919] COMPUTER CONTROLLED CUTTING 3 [0926] ELECTRONICS PRODUCTION 4 [1003] COMPUTER CONTROLLED MACHINING 5 [1010] FINAL PROJECT UPDATE 6 [1017] MOLDING / CASTING / COMPOSITES 7 [1024] EMBEDDED PROGRAMMING 8 [1031] 3D SCANNING + PRINTING 9 [1107] INPUT DEVICES 10[1114] OUTPUT DEVICES 11[1121] INTERFACE + APPLICATION PROGRAMMING 12[1128] MECHANICAL + MACHINE DESIGN + FINAL PROJECT UPDATE 13[1205] NETWORKING + COMMUNICATIONS 14[1212] FINAL PROJECT DEVELOPMENT 15[1219] FINAL PRESENTATIONS

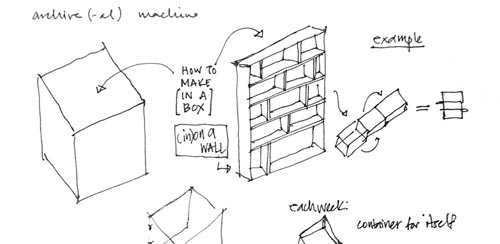

1 archive[-al machine]

For

the final project, I'd like to make an physical archive for the work

completed in this class. Reflecting on the semester, we've learned so

many different things. Coming in with no background in electronics or

programming, I'd like to use the final project as an opportunity to

re-work some of the projects from the semester in the form of an

archive. Think of as [How to Make Almost Anything, in a box] or [the

idiot's guide to how to make almost anything.]

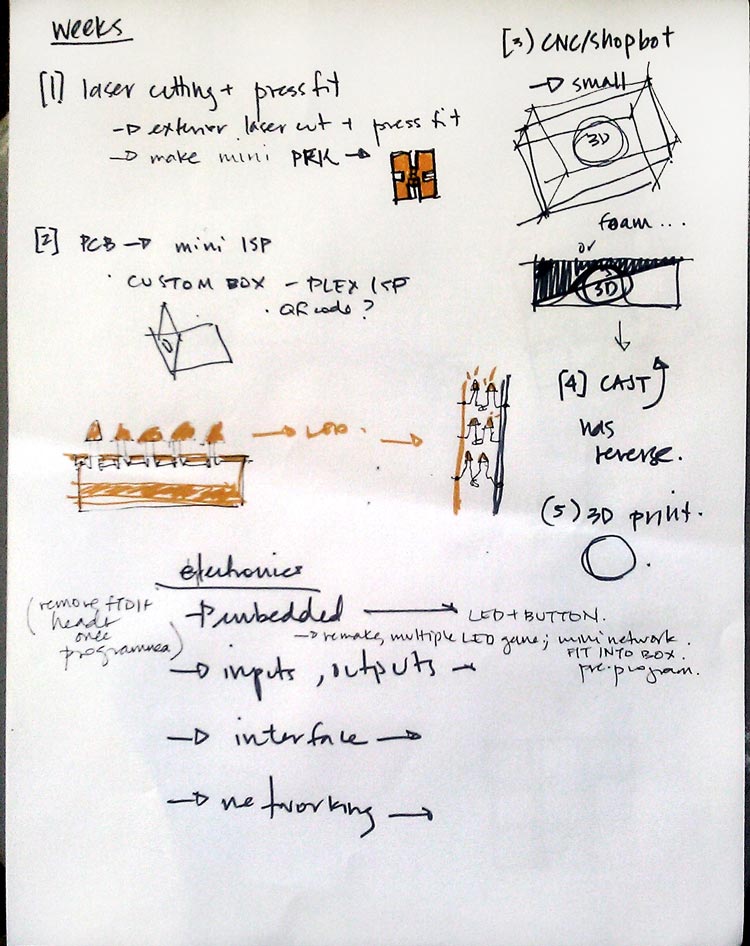

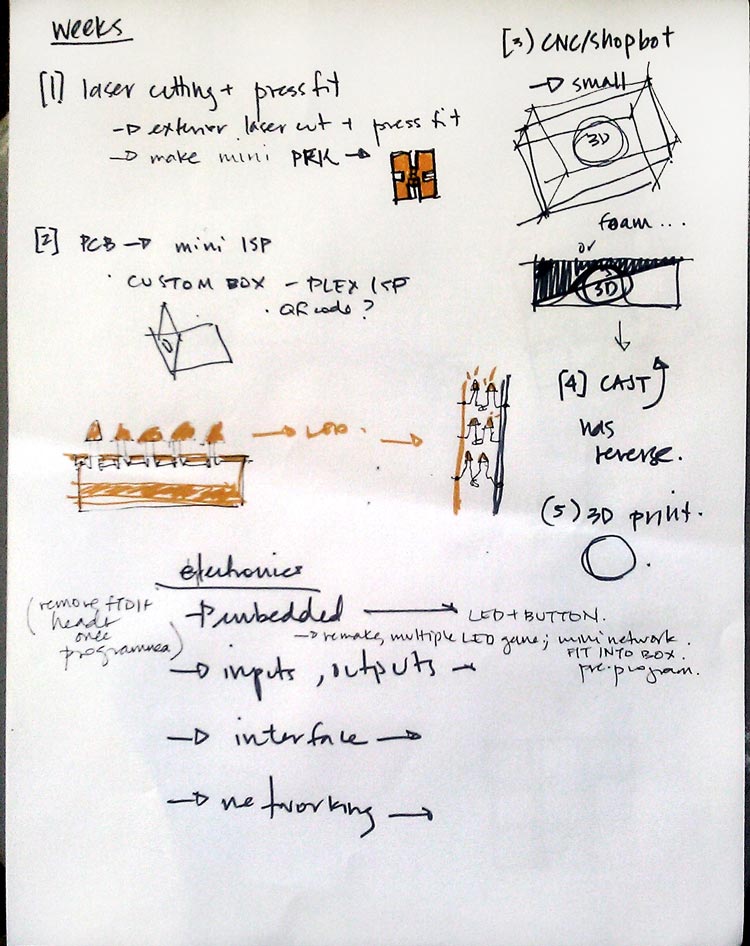

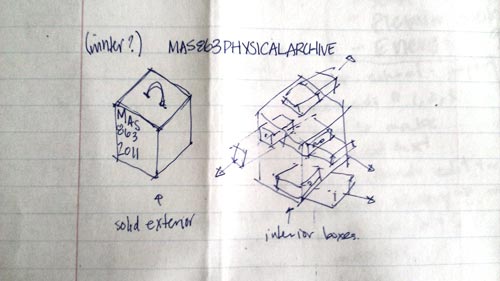

This past week,

I went through a couple of design ideas to figure out what I can

definitely complete.

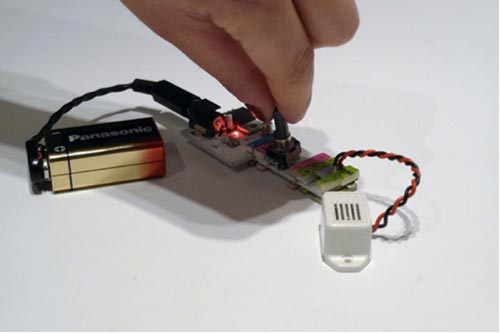

12-containers (1-weeks' work each) with an

exterior circuit. When parts are connected, LEDs code will run

through.

GOAL

1: is

to complete the press-fit structure, along with the embedded LEDs,

and code.

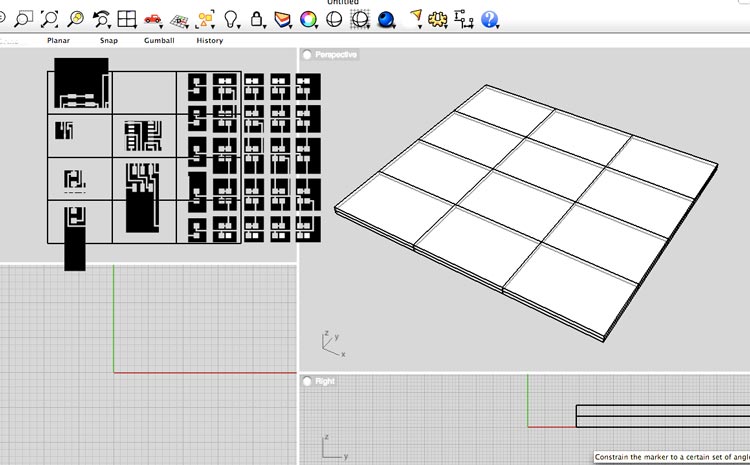

(1) make wooden blocks

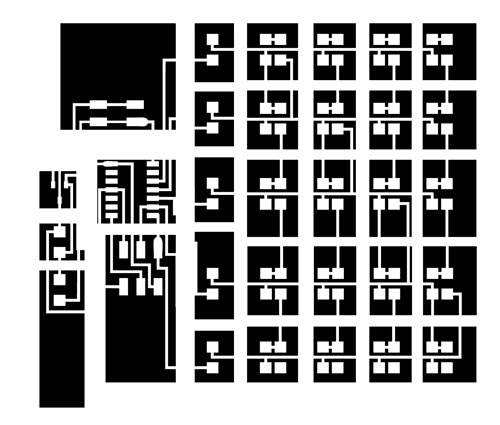

(2) redesign charlieplex

circuit for 12-block / RGB LED (add accelerometer? Color can change

w/ speed or orientation)

(3) vinyl cut XL circuit

(4) stuff XL

circuit onto each block

(5) figure out how to incorporate magnets

to look locations (mill, drill, ?)

(6) test circuit

GOAL

2: two

plexi-containers, press fit/etc.

(1) circuit-embedded

(2)

cnc/shopbot/3D print/cast combo (pick one, since these should be

related, perhaps possible to complete more)

notes: try either

etching, or sandblasting to see if vinyl sticks better, no vinyl,

just magnets at connection points?

GOAL

3:

finish

(1) make other plexi containters > do not have to have

material embedded, just plexi boxes?

(2) re-cut vinyl circuit,

stuff

(3) test …

(

)

)

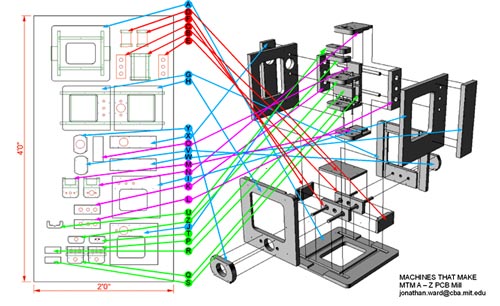

Step

1 is

to evaluate the projects from each week, and decide on an overall

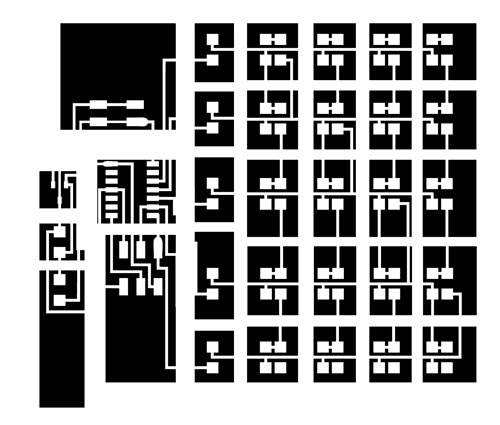

thematic. Having produced a first iteration of all the projects, and

considering everything I have learned thus far, I will re-produce the

work for each week. I'd like to start with 3D printing and casting;

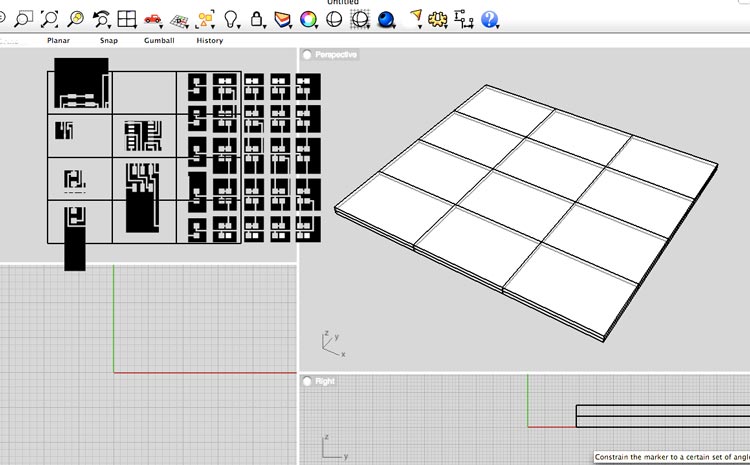

and I've already started to re-make some of the eagle boards for the

pcb's from various weeks, (images from last week) so these, along

with instructions can be incorporate as well.

MATERIALS:

basic:

1/4”

PLEXI for press-fit

LEDs (equal number, one for each week's

container)

consider

week specific:

1

– laser cut

2 – producing the FABtiny

3 – shopbot and/or

waterjet

some

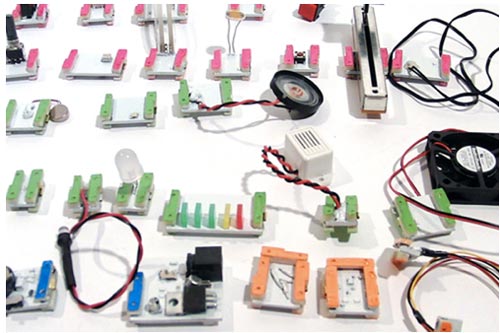

more precedents/physical computing

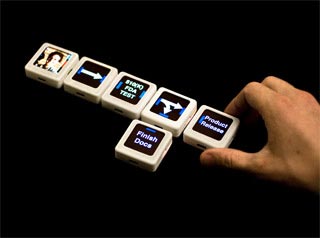

LittleBits

video link

also:

MIT's Siftables.

MIT's Siftables.

The

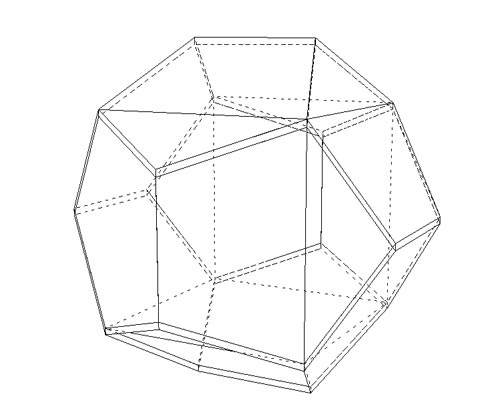

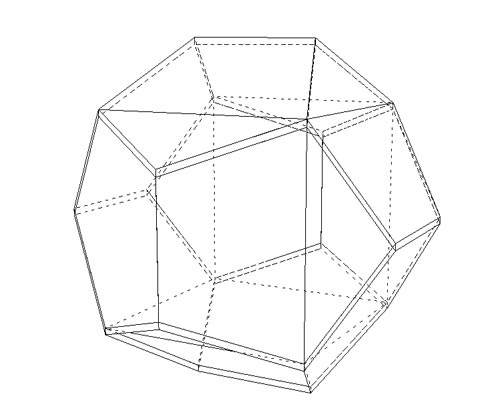

archive[-al] machine is a press-fit physical archiving system;

made to display and teach the viewer about basic concepts of

fabrication.

+

+

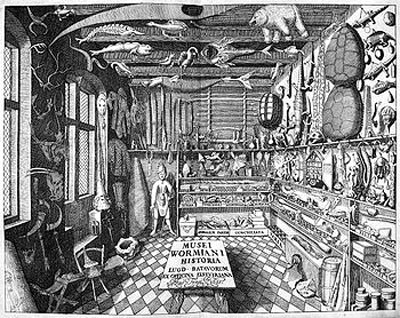

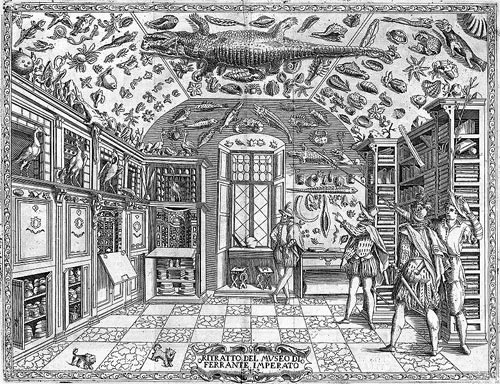

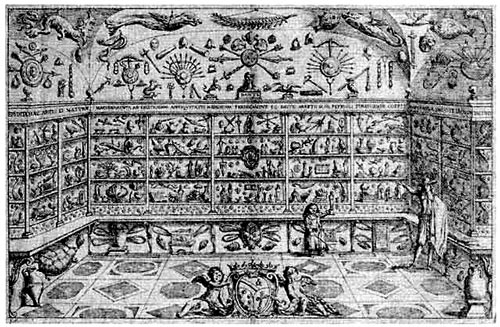

prior

art:

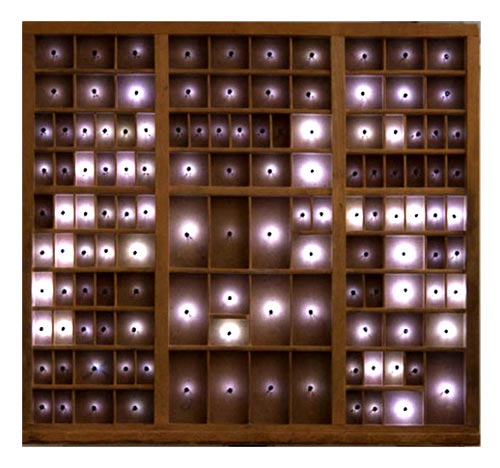

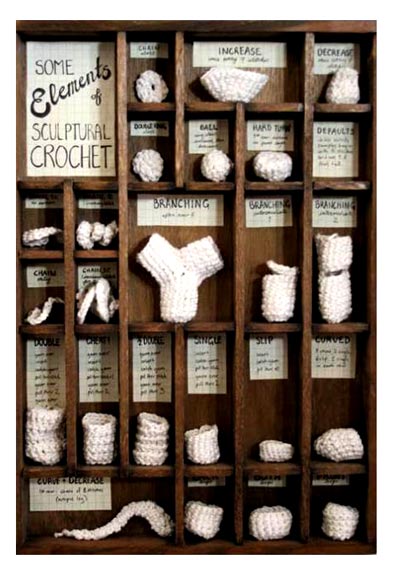

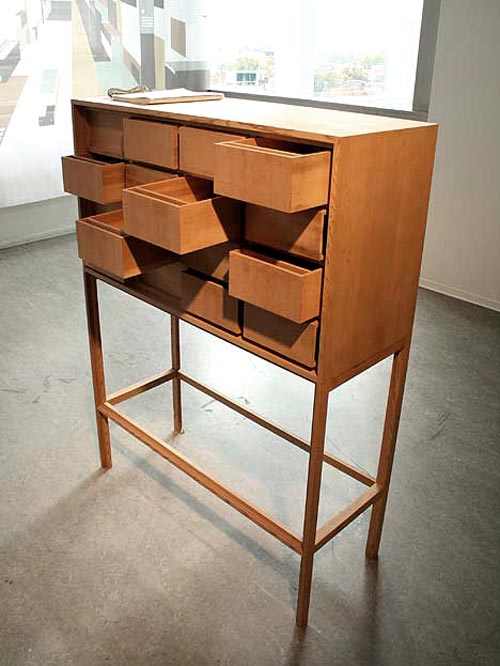

NATURAL

HISTORY + CURIOSITY CABINETS

RE-INTERPRETED;

DISPLAY FOR GLASS-BLOWN SPECIMENS / SCULPTURAL CROCHET DISPLAY

PHYSICAL

/ DIGITAL RE-INTERPRETATIONS; CABINET W/ RFID TAGS

VIDEO

HERE

VIDEO

HERE

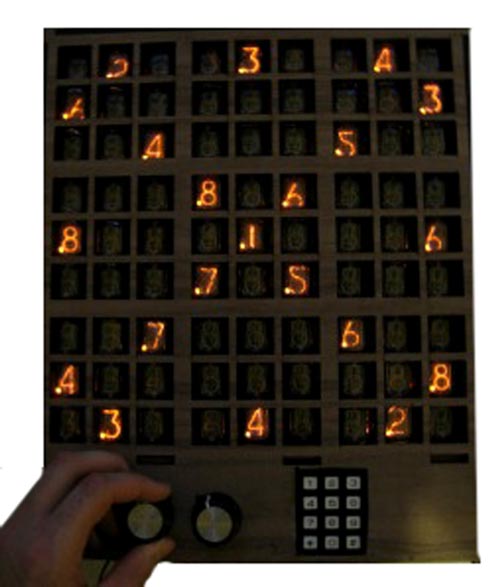

LED

ARRAY TYPECASE / SUDOKU (click on the image for original page)