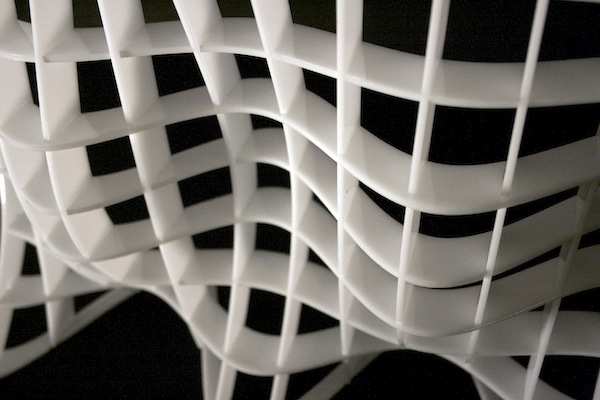

PRESS-FIT LATTICE

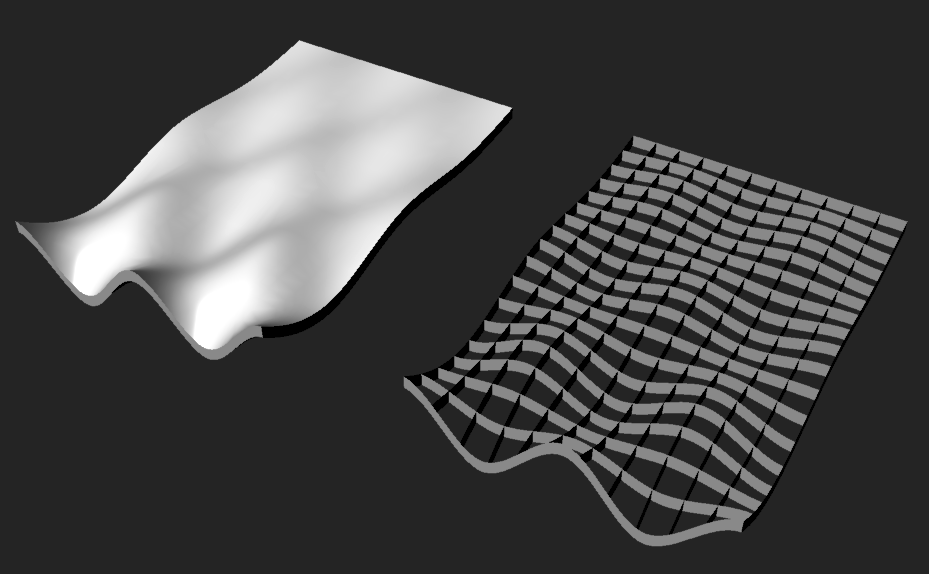

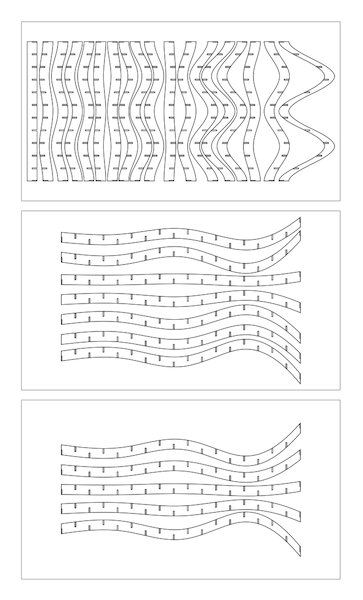

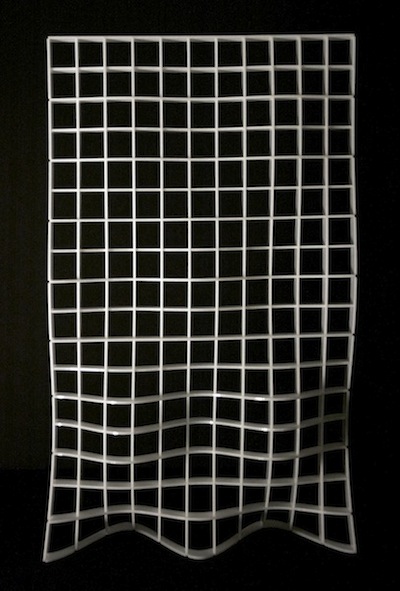

First, I designed a surface in rhino and gave it thickness. I then found the lattice structure that approximated that volume. I separated each segment of the lattice and put notch marks at the intersecting points so that the pieces would fit together.

An important lesson I learned while doing this was to use the calipers to find the exact thickness of the material, not the advertised thickness. I ran into a few problems before I found out that the .125 inch thick material was closer to .115 inches thick.