PCB FABRICATION

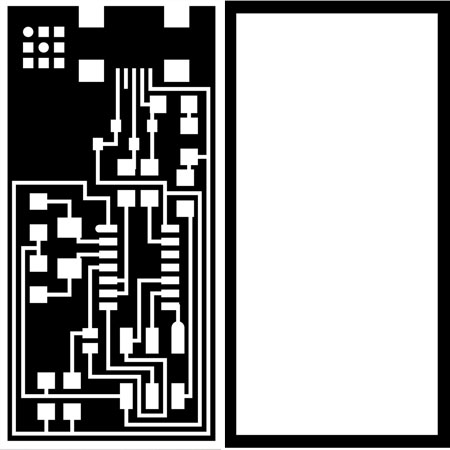

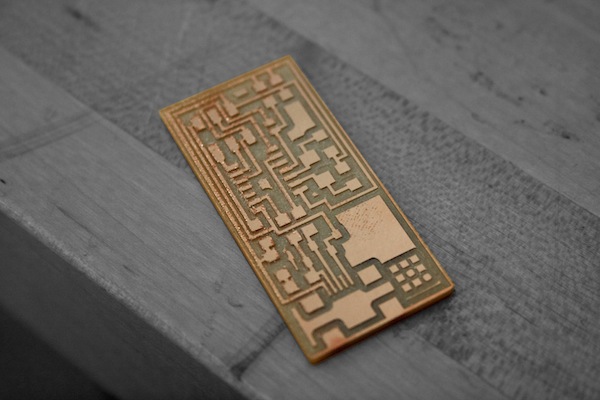

Milling the Board

- I started by pressed view button to allow me to use double stick tape to secure

the board

- Then I pressed view again to allow me to change the bit

Problem: My first problem occurred here. When I was trying the change the bit

the set screw seemed to be missing. As it turned out, there was only one,

which was on the far side of the bit, out of sight. I simply had to turn the

bit to get access to it. It was a silly issue but it cost me 7 minutes (in failed

attempts, looking up instructions, and asking for help).

- After that I opened the Fab Module and selected the option for the Modela.

- I pressed view again and sent the Modela to the x,y zero (5,5) to allow me to set the

z zero by moving the bit down.

- Then I selected the png option to cut two board traces and made the cut lines. I set

the z to -0.3 (by advice of the person that came before me).

Problem: The first time I set all of the options and sent the job. The cuts were

too shallow and didn't look correct. I realized that I the setting of the module

on 'default' instead of 'milling traces.' And so I had to kill the job (by turning

the machine off, then on, the holding up and down buttons, then entering a script

into terminal).

- Finally, after an hour or so, I had milled two boards. Here's one, which seems slightly

defective, maybe due to cutting too deep:

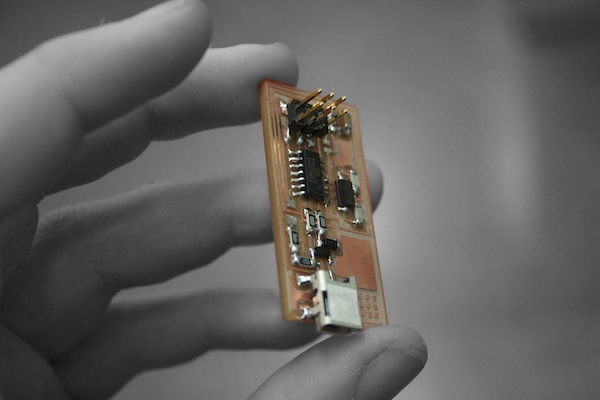

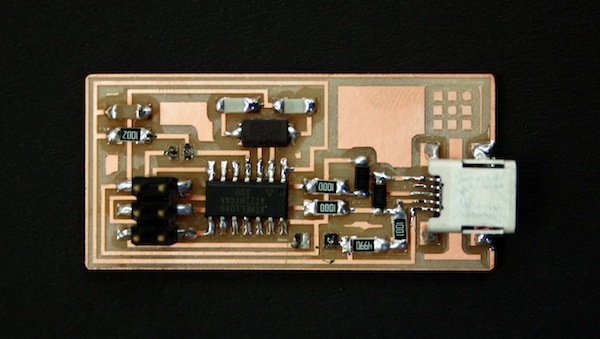

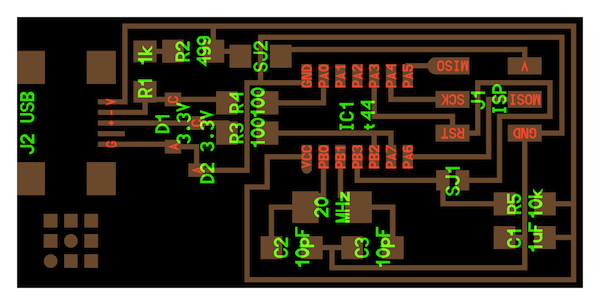

Stuffing the Board

- For me, a person unfamiliar with soldering, these small components are slightly

frightening. But after the tutorial, I found it quite easy.

- I started with the smallest components (such as the resistors) and worked my way up

to the larger ones.

Problem: After soldering all of the components and trying to program it unsuccessfully,

I realized I soldered the wrong microcontroller (Tiny 84 instead of Tiny 44) onto

by board. In order to quickly take it off, Moritz used the heat gun to heat all of

the solder of the board and the microcontroller was able to be pucked off. The heat

gun was used again to heat the leftover solder and I simply placed the correct

microcontroller on the board.

- Then I connected the board to the computer and ran the script to program the board.