MAS 863: How to Make (Almost) Anything

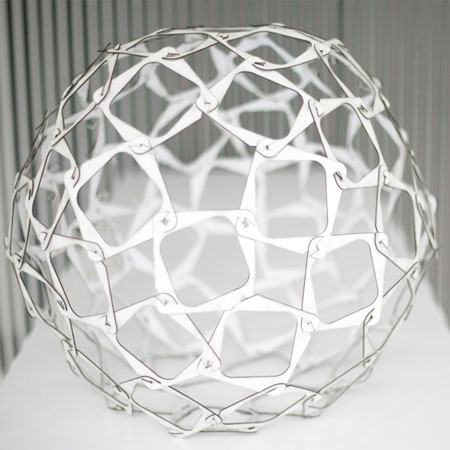

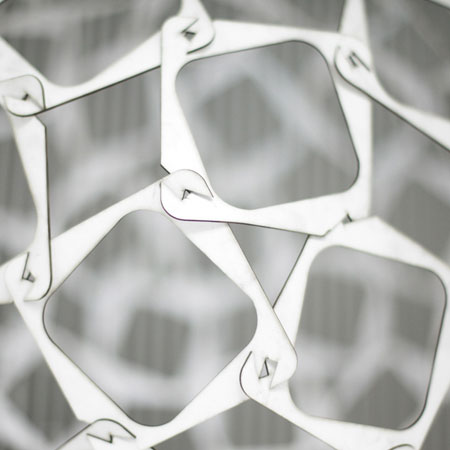

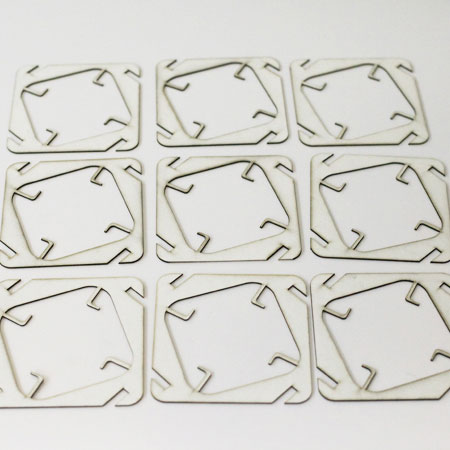

The ball is made of 60 pieces of squares. All the squares have the same size and cut. It doesn't need to be holo in the middle. A cut ismade in each corner to join the two corners from two connected squares.

I made this design based on Yoshinobu Miyamoto's explanation about icosahedron.

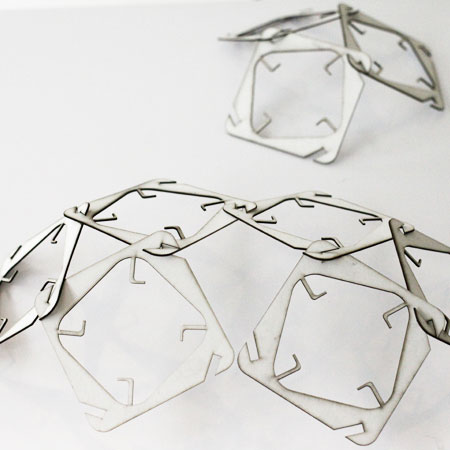

1) Connect 3 pieces into a triangle. Make 20 sets.

2) Connect 5 triangles together. Each two triangles forms a diamond shape in the middle.

3) Connect another 5 around 2), leave one without connection in between.

4)

Connect the other 5 around 3).

The width of the cut is an important parameter. If it's too wide, the ball will fall apart very easily. But if it's too narrow, it's hard to get a smooth surface.

Thinner materials work better.

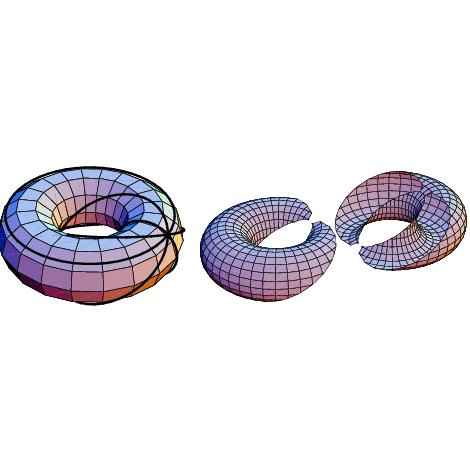

Different from the former ball, which shape is made of the surface pieces, the torus has an entire 3D shaped built out of card board.

Again, I got inspired from Yoshinobu Miyamoto, Architect and Professor at AIT ( Aichi Institute

of Technology, Japan). His origional tutorial is for paper. I am trying to duplicate his result using cardboard with certain thickness. Although each piece can fit very nicely, it was very hard to assemble them together. The main reason was that there was little space for me to arrange 16 pieces at the end. I can imagine it's going to be easier if the unit was bigger.

Each pair of the pieces form a Villarceau Circle, which is the 3rd circle along the torus surface after the verticle and horizontal section.

Download link of the source file for both projects