apply flush cutters to stop on gear

Final Project Update

Welllll....

dumb test:

Vending machine

Right, essentially two weeks until final projects due. Aka time to start cramming on vending machine.

What do I have on hand? Arduino uno, extra servos leftover from when I bought out all the old 2.007 servos., zipties, handheld drill, a corkscrew. Found some rectangular metal thing to act as guiderails lying around MITERS scrap pile. Also found a block of wood lying around the floor.

Mod a servo to be continuous rotation (essentially turn it into a cheap RC motor that comes with motor speed controller) --

aka remove mechanical stop on gear

|

apply flush cutters to stop on gear |

and remove pot, which like all pots doesn't turn infinitely -- make sure to be gentle 'cos pot is held in by internal screw, why it doesn't just fall out normally

|

see blurry screw at bottom. Also, I wasn't gentle and cracked the PCB. Maybe it is inevitable for these servos (motor is soldered onto pcb so not much flexibility there) to get to pot screw. Surprisingly the servo still works... |

|

stick pot on outside, chew a hole for it in the casing -- i abused flush cutters |

see How to Hack a Servo by Daniela Faas http://stellar.mit.edu/S/course/2/sp11/2.007/courseMaterial/topics/topic12/other/Servo_Hack_large/Servo_Hack_large.pdf)

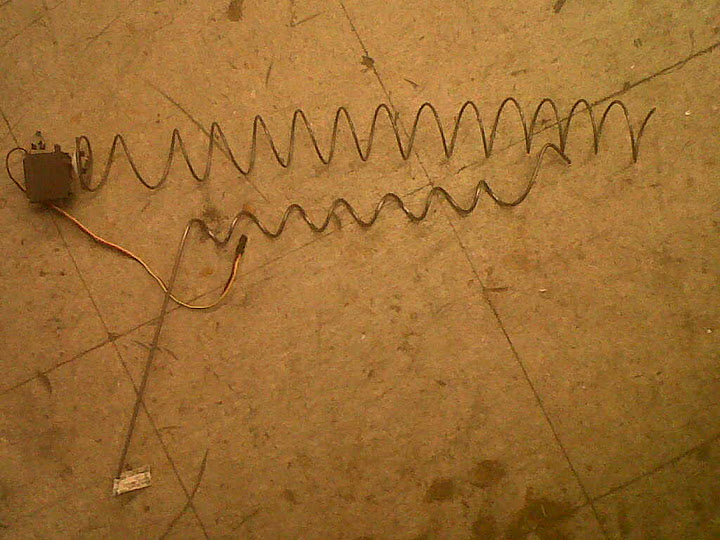

Attach to corkscrew (from real vending machine) I bought off of ebay to see what real mass manufactured ones are like so I can make fake ones DIY like http://www.instructables.com/id/Make-your-own-springs-in-seconds/

Drill out servo horns (1/8'' bit fits zipties I found) and attach to corkscrew with zipties

|

it vends a block! haha. terrible setup is terrible. |

Video here:

https://picasaweb.google.com/113942194695013581888/VendingMachineOpenHardware#5681154916854562050

Yea, not a very interesting proof-of-concept (a "duh are you an idiot" one), but it was very satisfying to me.

Oh right, I tried to use hot glue to hold the pot in one place, since that affects how the servo reacts to servo.write() (pot adjusts when it goes fwd/reverse) -- I just used

myServo.write(50) with a 0.5 sec delay

myServo.write(90) with a 3 sec delay

myServo.write(130) with a 0.5 sec delay

to calibrate the pot so that servo was completely still at 90. And then attempted to hot glue, not good enough for long-term banging around but good enough for dirty proto.

|

yes, i stole arduino from hexarideablepod. arduino uno with a small breadboard on top and 3 male header pins to connect arduino (Vcc, Gnd, and SIG -- arbitrarily pin 2 in my case) and servo. unplugged in this pic. |

Not clear from pics, but to test it I'm holding the servo still with my hand.

====

Spring making as told on instructables

“Many years ago I used to make springs this way on a lathe. We used commercially available untempered spring wire and after we finished we heated up the spring to red hot and dropped it into fish oil to temper it.

Some times we would make special custom springs by soft annealing standard off the shelf springs and straightening them to salvage the wire. Then we would rewind them to suit the job at hand and re-temper.”

very uneven, will need to do more trials (there went $5 of weldable steel rod, ⅛’’). went very quickly, even by hand.

probably still need use light sensor detect when item vended, safer b/c of uneven nature of coils (can’t dead reckon with degrees of rotation)

====

todo: order light-up buttons, rfid reader, more servos (or hijack from hexadancingpod :/)

Doesn't do so hot on the drill. Mess with timing? Although I spun it slow and fast (and in-use yoyo spins quite fast). May require sensors (fan pov as seen on dealextreme -- product designer has better idea of speed of motor while yoyo has more variable speed. maybe they used hall effect sensors, 'cos it was resilient to me slowing down the blades.) to get stable image.

See video:

https://picasaweb.google.com/113942194695013581888/PoVYoyoPersistenceOfVision#5681157457783660930