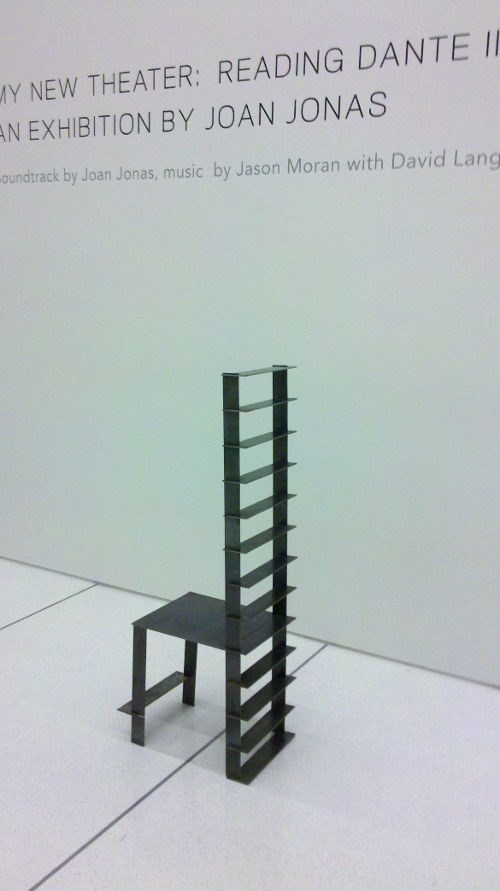

how to make something BIG

King Francis meets Corbusier [cor-BIG]

Watch this video

Watch this video

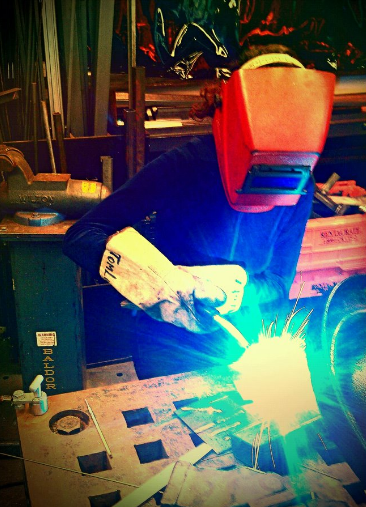

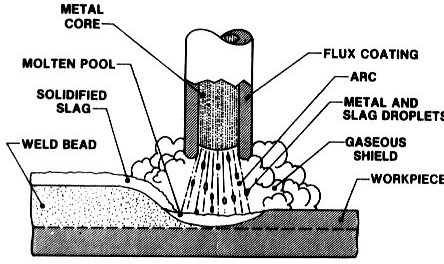

Welding

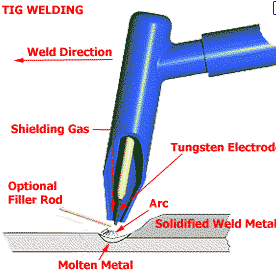

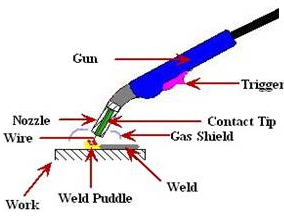

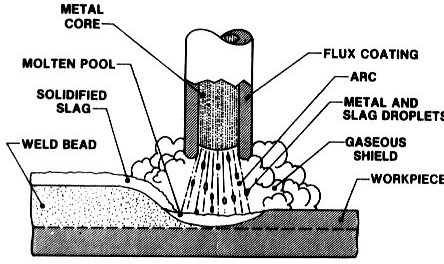

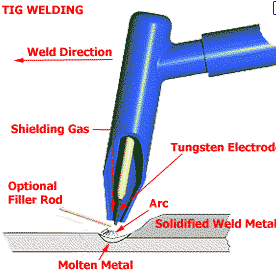

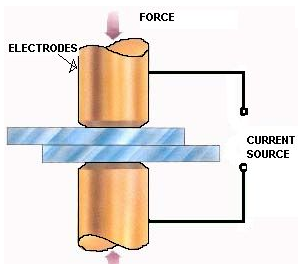

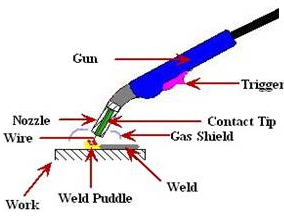

John and Tom gave a nice demonstration for welding techniques. Tig welding can be used for alloys, steel, nickel based alloys, and aluminum.The key feature is that Tig involves a slow weld, where the surface of contact needs to be as clean as possible. Stick Welding is characterized by a stick electrode which is covered with a flux exterior, and upon exposure to gas shields the weld and allows for a robust, simple and under any environment the ability to create a solid weld. Mig welding is the fastest, and all purpose general fabrication technique where the metal does not have to be thoroughly cleaned before it's used. One main feature is the inclusion of a spool, made out of steel or aluminum wire to allow for any type of welding. Tips for Mig include keeping the tip as close to the material as possible, and moving your hand in a figure eight fashion to make sure the weld covers every spot.

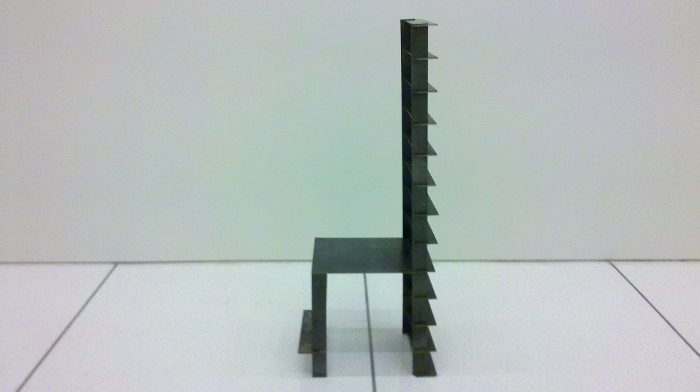

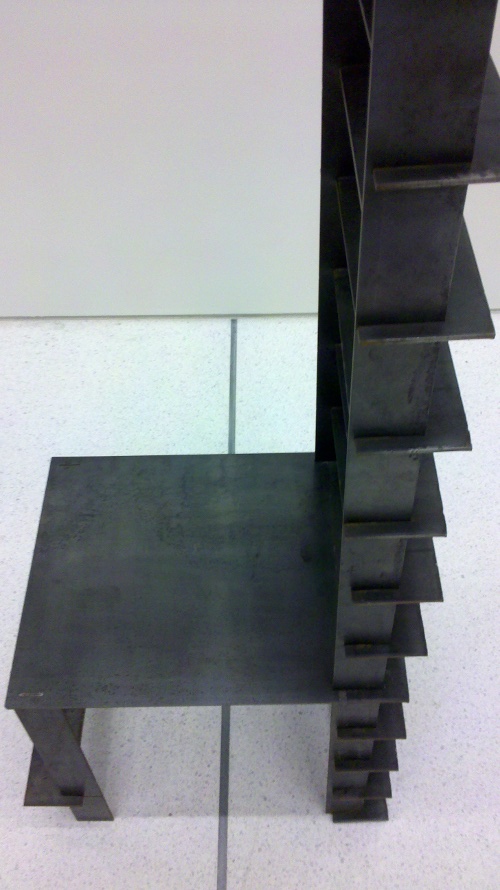

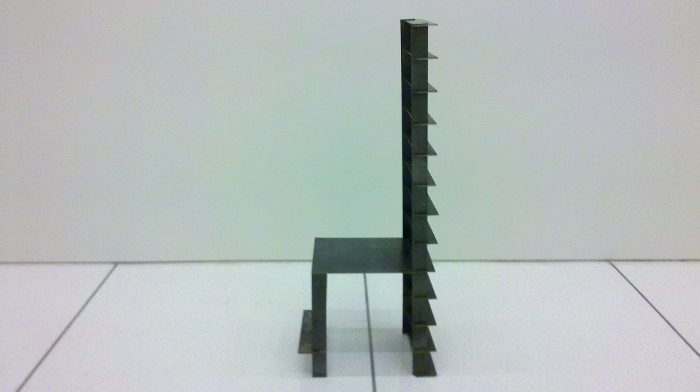

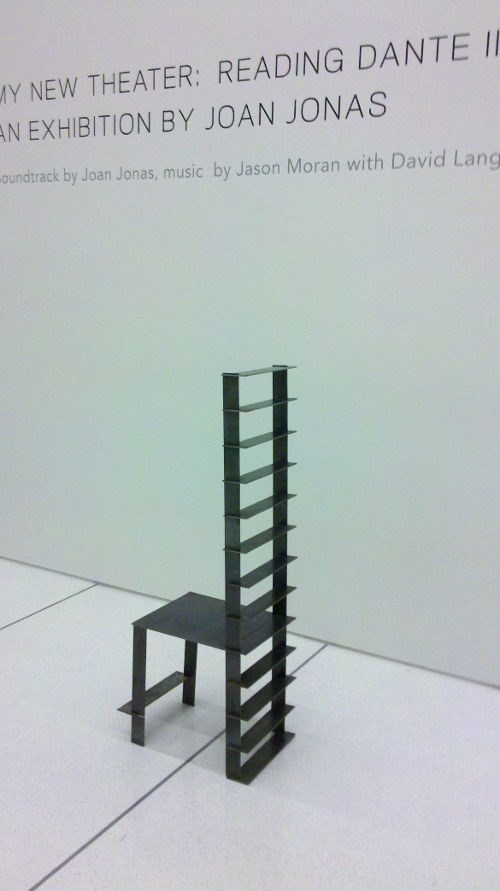

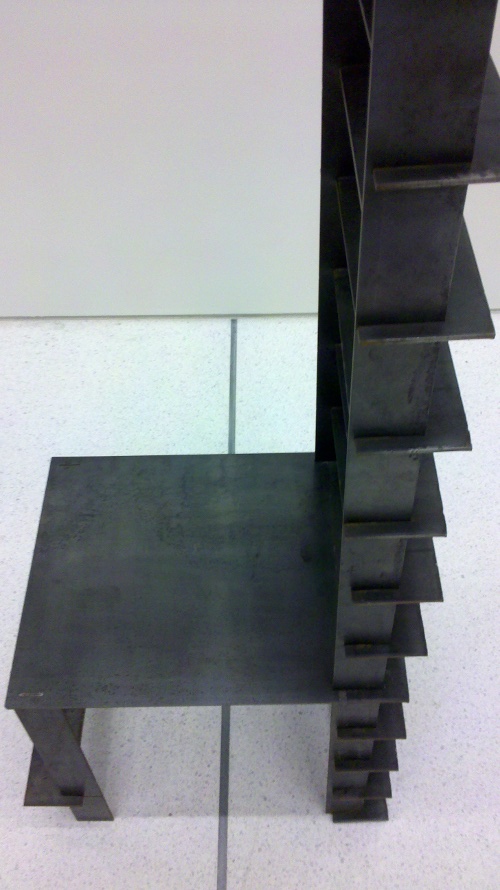

SnapFit Steel Parts

I used the WaterJet a second time to test snap fitting out of aluminum and steel sheets. The process took about a day to debug, from interoperability of the file between CATIA and OMAX Layout, to getting the right tolerances for a good snap together joint that didn't require too much force to assemble. The parts are more difficult to disassemble once in place, and the notches within designed for flexure are weakening the material where it is evident that the extensions are deforming more than they should be in many areas of the structure. This was dealt with by simple hammering all the joints in x,y,z directions to make sure everything fit precisely and that no extra bending was occuring anywhere in the structure. The following video illustrates ease of assembly. Another thing to note: the parts were cut above the water surface, because of the smaller scale of the components which created a lot messier of a process than if they were to be cut underwater. This machine is amazingly powerful, and is close to being my favorite so far, but it takes time to really understand how best to setup your file and tolerances to make the most of the machine. I want to stress: this is not the best setup if you want to cut a lot of parts. It will take an enormous amount of time, and just for 24 parts per sheet, I had a cut time of 1 hour and 30 minutes. It's good to assess why you are using this machine, and to see if you can get the job done quicker on say the 500W laser cutter etc.

Watch this video

Watch this video

Watch this video